random user submitted photo

Jab burping Update - issue resolved

21 posts

• Page 1 of 3 • 1, 2, 3

Jab burping Update - issue resolved

All,

I've been requested by several Sonex flyers to provide an update to the group on my resolution to the Jab3300 burping issues I've been continuously experiencing over the last 2 years. I had 90 hours on my plane (Jab3300 Waiex) at the point in time when the below event happened. I had originally implemented the plans stock setup for fuel line plumbing with gascolator. There was no dips in the system, it was a good climbing run from the firewall penetration to the Aerocarb. I had heavily insulated the whole system after experiencing burping originally - which helped only moderately. I then removed the gascolator and replaced with a filter on the forward side of the firewall. This helped some, but I still had burp issues at times. After a 1.9 hour flight from central Iowa down to Kansas City two months ago, I grounded the Waiex for safety reasons upon my return. One other note - the times when I ran pure 100LL with no Auto fuel mix, I never really experienced this burping issue. However, since Av gas at my home airport has been near $6.75 per gallon a lot of the times - from a fiscal responsibility standpoint, I needed to put due diligence into solving the Auto fuel issue before standardizing only on Av gas.

Below is the sequence of events and conditions on the trip to Kansas:

1)During the last 15 minutes of flight down I began to experience hiccups and surges of the engine, some moderately severe. I was using only auto fuel on the way down (premium, no Ethanol or 100LL mix). Temps were cool at the start of flight, but I kept the engine at 2700 rpm and the engine compartment heated up eventually as the hottest CHT's were around 300f and the hottest EGT's around 1320f the majority of the flight. Oil temps hit up to 210f.

2)Upon arrival in Gardner, Ks, I put about 9 gallons of 100LL in the tank (about 6 gallons of premium auto fuel left), then stayed there for 10 hrs watching a bunch of WW1 replicas flying. Temps during the day were mid 80"s outside, probably 120+ in the cockpit with the canopy cracked open a tad.

3) At takeoff, temps were still in the 80's. During climb out I pushed the plane pretty hard to get to altitude. CHT's hit low 300's again and the engine compartment really heated up. Within about 5 minutes, the burps were back in full force. During the entire first hour flight back (just about 5.5 gallons of fuel burn), the engine continued to burp (and at times stutter) every 15-20 seconds or so. Oil temps hit 212-215f. I was very close to landing the plane somewhere and trailering it back. (In retrospect, I absolutely should have - lesson learned). I'd never seen it burping this bad and throttled back significantly (2500rpm) to take some heat out of the engine compartment.

4) After one hour of flight, the burping began to decrease and then stopped all-together. Ambient temps had dropped to the mid 70's and the CHT's had cooled to 290's.

What I couldn't figure out was if the auto-fuel and 100ll had separated somewhat during the day and I was now burning mostly 100LL (different density?), or if the engine compartment had cooled enough that I wasn't vaporizing the fuel anymore. Either way, I had to change the system.

I finally realized that there were an number of issues with the original setup that could pretty easily be mitigated:

1) Air off the back of the oil cooler was preheating the carb and fuel significantly. It is a direct shot from the cooler to the carb, and the carb was HOT when I checked it after a flight one time. This was probably a major issue for me.

2) The air out of the oil cooler was basically piling up in the back of the cowling and not allowing for smooth air flow out through the bottom. The cowling was HOT all the way back to the firewall. This was a possible source for oil temp issues. Air inlet and exhaust were sized correctly.

3) The exhaust collectors and pipe are pretty close to the fuel line going into the carb. At one point, you will be within about 4-5".

4) I needed to simplify the fuel system to reduce the exposure to heat.

My solution to this was to yank the entire fuel system out and start over. I took the following mitigation steps:

1) Changed the fuel line routing to a straight line descending path from bottom of header tank, directly through the firewall to the Aerocarb. Since the line is straight, short and constantly descending, any vapor bubbles would easily migrate up the line into the fuel tank. By removing the stock setup, I removed at least 18" of fuel line and four 90 degree bends out of the system (3 inside the cockpit, 1 on the engine side of the firewall.

2) I moved the Stratomaster Flowscan fuel flow measurement device from the front of the firewall to just downstream of the fuel on/off valve inside the cockpit. This removed another potential heat sink in the firewall forward area.

3) I moved the fuel filter to near the inlet of the Aerocarb - a moderate 90 degree AN adaptor between the two.

4) All hoses are very heavily insulated and fire wrapped. They also have heating duct reflective tape wrapped around them. (Same as before)

5) I made a 14" wide heat deflector and installed it on the top of the oil cooler and it bends down in a curve in front of the carb yet still remains behind the exhaust pipes- redirecting air directly out the bottom of the cowl. 14" is wide enough to block the back of both exhaust pipes. Since it is also directly behind the exhaust pipes, it is deflecting the heat from them directly out the bottom of the cowl also. This has had huge impact - I'll explain result at the bottom of this message.

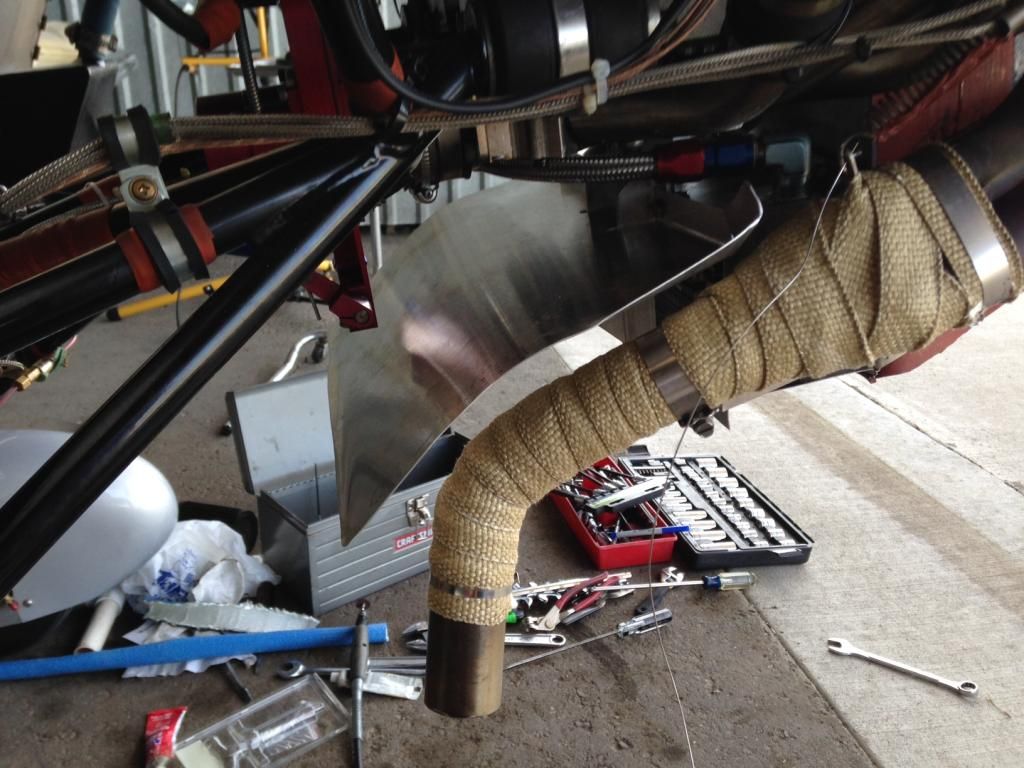

6) I wrapped racing exhaust tape around the lower pipe collectors and exhaust pipe ONLY. I did not wrap the individual pipes above the collector.

Results to date after 10 hours over abusive flying in warm weather

1) Burps are completely gone. Even when the system is heat soaked and I'm taxiing back to the hanger, I get no engine surges. I can make multiple flights during a hot afternoon and not worry about heat soaking the fuel system and vapor bubble issues. I am now comfortable on long flights (did 2+ hours yesterday at 2850rpm)

2) Oil temps dropped from 190/200+ continuously down to 170 continuously. This is a direct result of the air flow being directed immediately out the bottom of the cowling.

3) Cowling that was very hot all the way back to the firewall is now much cooler midway back and ambient temp at the firewall.

4) I need to install a new #3 needle and retune it. Since I removed a significant amount of parasitic line resistance to fluid flow due to the removal of the extra line and multiple 90 degree turns, head pressure is up and the existing needle is carved way too aggressive. I currently have to do a lot of aggressive leaning. I do get near 3300WOT finally however...

5) I was unable to cruise at higher than 2700rpm previously, otherwise the cowling temps got high enough that the engine started burping. Now I can run at 2850 - 2950rpm for extended periods of time and lean it out for great fuel economy.

Anyway - long winded, but I wanted the group to be aware. I hope this helps somebody.

Lorin Miller

N81YX

I've been requested by several Sonex flyers to provide an update to the group on my resolution to the Jab3300 burping issues I've been continuously experiencing over the last 2 years. I had 90 hours on my plane (Jab3300 Waiex) at the point in time when the below event happened. I had originally implemented the plans stock setup for fuel line plumbing with gascolator. There was no dips in the system, it was a good climbing run from the firewall penetration to the Aerocarb. I had heavily insulated the whole system after experiencing burping originally - which helped only moderately. I then removed the gascolator and replaced with a filter on the forward side of the firewall. This helped some, but I still had burp issues at times. After a 1.9 hour flight from central Iowa down to Kansas City two months ago, I grounded the Waiex for safety reasons upon my return. One other note - the times when I ran pure 100LL with no Auto fuel mix, I never really experienced this burping issue. However, since Av gas at my home airport has been near $6.75 per gallon a lot of the times - from a fiscal responsibility standpoint, I needed to put due diligence into solving the Auto fuel issue before standardizing only on Av gas.

Below is the sequence of events and conditions on the trip to Kansas:

1)During the last 15 minutes of flight down I began to experience hiccups and surges of the engine, some moderately severe. I was using only auto fuel on the way down (premium, no Ethanol or 100LL mix). Temps were cool at the start of flight, but I kept the engine at 2700 rpm and the engine compartment heated up eventually as the hottest CHT's were around 300f and the hottest EGT's around 1320f the majority of the flight. Oil temps hit up to 210f.

2)Upon arrival in Gardner, Ks, I put about 9 gallons of 100LL in the tank (about 6 gallons of premium auto fuel left), then stayed there for 10 hrs watching a bunch of WW1 replicas flying. Temps during the day were mid 80"s outside, probably 120+ in the cockpit with the canopy cracked open a tad.

3) At takeoff, temps were still in the 80's. During climb out I pushed the plane pretty hard to get to altitude. CHT's hit low 300's again and the engine compartment really heated up. Within about 5 minutes, the burps were back in full force. During the entire first hour flight back (just about 5.5 gallons of fuel burn), the engine continued to burp (and at times stutter) every 15-20 seconds or so. Oil temps hit 212-215f. I was very close to landing the plane somewhere and trailering it back. (In retrospect, I absolutely should have - lesson learned). I'd never seen it burping this bad and throttled back significantly (2500rpm) to take some heat out of the engine compartment.

4) After one hour of flight, the burping began to decrease and then stopped all-together. Ambient temps had dropped to the mid 70's and the CHT's had cooled to 290's.

What I couldn't figure out was if the auto-fuel and 100ll had separated somewhat during the day and I was now burning mostly 100LL (different density?), or if the engine compartment had cooled enough that I wasn't vaporizing the fuel anymore. Either way, I had to change the system.

I finally realized that there were an number of issues with the original setup that could pretty easily be mitigated:

1) Air off the back of the oil cooler was preheating the carb and fuel significantly. It is a direct shot from the cooler to the carb, and the carb was HOT when I checked it after a flight one time. This was probably a major issue for me.

2) The air out of the oil cooler was basically piling up in the back of the cowling and not allowing for smooth air flow out through the bottom. The cowling was HOT all the way back to the firewall. This was a possible source for oil temp issues. Air inlet and exhaust were sized correctly.

3) The exhaust collectors and pipe are pretty close to the fuel line going into the carb. At one point, you will be within about 4-5".

4) I needed to simplify the fuel system to reduce the exposure to heat.

My solution to this was to yank the entire fuel system out and start over. I took the following mitigation steps:

1) Changed the fuel line routing to a straight line descending path from bottom of header tank, directly through the firewall to the Aerocarb. Since the line is straight, short and constantly descending, any vapor bubbles would easily migrate up the line into the fuel tank. By removing the stock setup, I removed at least 18" of fuel line and four 90 degree bends out of the system (3 inside the cockpit, 1 on the engine side of the firewall.

2) I moved the Stratomaster Flowscan fuel flow measurement device from the front of the firewall to just downstream of the fuel on/off valve inside the cockpit. This removed another potential heat sink in the firewall forward area.

3) I moved the fuel filter to near the inlet of the Aerocarb - a moderate 90 degree AN adaptor between the two.

4) All hoses are very heavily insulated and fire wrapped. They also have heating duct reflective tape wrapped around them. (Same as before)

5) I made a 14" wide heat deflector and installed it on the top of the oil cooler and it bends down in a curve in front of the carb yet still remains behind the exhaust pipes- redirecting air directly out the bottom of the cowl. 14" is wide enough to block the back of both exhaust pipes. Since it is also directly behind the exhaust pipes, it is deflecting the heat from them directly out the bottom of the cowl also. This has had huge impact - I'll explain result at the bottom of this message.

6) I wrapped racing exhaust tape around the lower pipe collectors and exhaust pipe ONLY. I did not wrap the individual pipes above the collector.

Results to date after 10 hours over abusive flying in warm weather

1) Burps are completely gone. Even when the system is heat soaked and I'm taxiing back to the hanger, I get no engine surges. I can make multiple flights during a hot afternoon and not worry about heat soaking the fuel system and vapor bubble issues. I am now comfortable on long flights (did 2+ hours yesterday at 2850rpm)

2) Oil temps dropped from 190/200+ continuously down to 170 continuously. This is a direct result of the air flow being directed immediately out the bottom of the cowling.

3) Cowling that was very hot all the way back to the firewall is now much cooler midway back and ambient temp at the firewall.

4) I need to install a new #3 needle and retune it. Since I removed a significant amount of parasitic line resistance to fluid flow due to the removal of the extra line and multiple 90 degree turns, head pressure is up and the existing needle is carved way too aggressive. I currently have to do a lot of aggressive leaning. I do get near 3300WOT finally however...

5) I was unable to cruise at higher than 2700rpm previously, otherwise the cowling temps got high enough that the engine started burping. Now I can run at 2850 - 2950rpm for extended periods of time and lean it out for great fuel economy.

Anyway - long winded, but I wanted the group to be aware. I hope this helps somebody.

Lorin Miller

N81YX

Last edited by ldmill on Mon Aug 11, 2014 9:58 pm, edited 1 time in total.

- ldmill

- Posts: 90

- Joined: Mon Nov 21, 2011 2:30 am

Re: Jab burping Update - issue resolved

Lorin,

Thanks for the report. Do you have any pics of the oil cooler air deflector?

Thanks for the report. Do you have any pics of the oil cooler air deflector?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Jab burping Update - issue resolved

Hi Bryan,

Yes, will get them posted this evening when I get home.

Lorin

Yes, will get them posted this evening when I get home.

Lorin

- ldmill

- Posts: 90

- Joined: Mon Nov 21, 2011 2:30 am

Re: Jab burping Update - issue resolved

I'm glad you've been able to solve the problem of running auto-fuel in your airplane.

I made this chart that shows the boiling ranges of 100LL and auto fuel. It was surprising to me that such a large percentage of the mass of auto-fuel can boil at such low temperatures.

The data for this graph assumes standard atmospheric pressure--it would be useful to see how the curves change at higher pressures due to our use of a header tank. It would also be interesting to see how it changes with altitude.

I made this chart that shows the boiling ranges of 100LL and auto fuel. It was surprising to me that such a large percentage of the mass of auto-fuel can boil at such low temperatures.

The data for this graph assumes standard atmospheric pressure--it would be useful to see how the curves change at higher pressures due to our use of a header tank. It would also be interesting to see how it changes with altitude.

- gammaxy

- Posts: 600

- Joined: Wed Sep 04, 2013 9:31 am

Re: Jab burping Update - issue resolved

Bryan,

I attempted to do the "Upload attachment", but got an error that the "board quota" had been hit - whatever that means. I can email it to you if you want.

Lorin Miller

I attempted to do the "Upload attachment", but got an error that the "board quota" had been hit - whatever that means. I can email it to you if you want.

Lorin Miller

- ldmill

- Posts: 90

- Joined: Mon Nov 21, 2011 2:30 am

Re: Jab burping Update - issue resolved

Lorin,

Sure! My email is my first and last name together with no spaces, at yahoo dot com.

Sure! My email is my first and last name together with no spaces, at yahoo dot com.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Jab burping Update - issue resolved

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Jab burping Update - issue resolved

Update on the update: After the fuel system change I was burning so rich at idle with my modified #3 needle that I was gassing myself out of the cockpit. I removed my modified #3 needle today and put in a stock non-modified #3 back in - following the factory procedure on how to initially set the needle. First start and run-up was flawless with WOT of 2850rpm static. I made absolutely no changes to the needle or setting beyond first installation. Below are results after 4 solid hours of flying today in mid 80 temps day with humidity of 45%+ and density altitudes that were getting up to 2900ft at a 950' high airfield. I performed 12 takeoff and landings to a full stop. I stopped and let the engine heat soak each time at my hanger for about 10 minutes before takeoff:

1) No vapor bubble stumbles or issues at all. Even during taxi.

2) In flight at full rich and 2850 rpm, my EGT's were low 1200's (significant drop from before). Lean of peak, they would rise to 1320 or so max. CHT's rich highest cylinder temp (#4) was in the 280's. CHT rich coldest temp (#6) would be at 255f. LoP CHT highest temp would be 307f.

3) At 2750rpm, Rich EGT's would drop to mid 1100's. LoP they would go to upper 1200's. CHT's rich - highest cylinder (#4) would drop to 270's. Coldest (#6) would be at mid 240's. LoP CHT highest temp would be 305f.

4) Putzing around at 2500 rpm and rich would put EGT's in the mid 1000f degree range. CHT's would be in the 250 degree range with all 6 cylinders within a temp spread of 15- 20 degrees f. LoP at 2500rpm and the EGT's would be in the 1250 range, CHT's would get to 270's with a max temp spread of about 30 degree's.

5) WOT was 3150rpm.

6) Oil temps never got above 185f.

Something new happened - during the takeoff run at full rich, when I would move the throttle forward, the engine would cough at me at least once, then get right back up and accelerate. Sometimes it would cough a couple of times. Not a nice thing to happen - it gets your attention. I found that if I didn't go full rich until after I hit 2200-2300rpm, then there would be no coughing. It appears to be slightly too rich at idle to be able to take a full throttle movement to run-up, even if not very abrupt. I may need to lean the needle a little.

One lesson I learned in this whole 100 hour burping/needle carving/carb tuning saga: tuning the Aerocarb means you absolutely have to have good fuel pressure. Carving on the needle for me was just a work around (hiding the fact) that I had a fuel pressure issue. Back several years ago when I set the needle originally per factory specs just like I did this time, and couldn't get over 2200rpm, that should have been a big hint that I had a fuel pressure issue. Instead I just started carving away...

All in all, it was the most satisfying day flying.

Lorin Miller

N81YX

Jab3300

1) No vapor bubble stumbles or issues at all. Even during taxi.

2) In flight at full rich and 2850 rpm, my EGT's were low 1200's (significant drop from before). Lean of peak, they would rise to 1320 or so max. CHT's rich highest cylinder temp (#4) was in the 280's. CHT rich coldest temp (#6) would be at 255f. LoP CHT highest temp would be 307f.

3) At 2750rpm, Rich EGT's would drop to mid 1100's. LoP they would go to upper 1200's. CHT's rich - highest cylinder (#4) would drop to 270's. Coldest (#6) would be at mid 240's. LoP CHT highest temp would be 305f.

4) Putzing around at 2500 rpm and rich would put EGT's in the mid 1000f degree range. CHT's would be in the 250 degree range with all 6 cylinders within a temp spread of 15- 20 degrees f. LoP at 2500rpm and the EGT's would be in the 1250 range, CHT's would get to 270's with a max temp spread of about 30 degree's.

5) WOT was 3150rpm.

6) Oil temps never got above 185f.

Something new happened - during the takeoff run at full rich, when I would move the throttle forward, the engine would cough at me at least once, then get right back up and accelerate. Sometimes it would cough a couple of times. Not a nice thing to happen - it gets your attention. I found that if I didn't go full rich until after I hit 2200-2300rpm, then there would be no coughing. It appears to be slightly too rich at idle to be able to take a full throttle movement to run-up, even if not very abrupt. I may need to lean the needle a little.

One lesson I learned in this whole 100 hour burping/needle carving/carb tuning saga: tuning the Aerocarb means you absolutely have to have good fuel pressure. Carving on the needle for me was just a work around (hiding the fact) that I had a fuel pressure issue. Back several years ago when I set the needle originally per factory specs just like I did this time, and couldn't get over 2200rpm, that should have been a big hint that I had a fuel pressure issue. Instead I just started carving away...

All in all, it was the most satisfying day flying.

Lorin Miller

N81YX

Jab3300

- ldmill

- Posts: 90

- Joined: Mon Nov 21, 2011 2:30 am

Re: Jab burping Update - issue resolved

This is very interesting reading indeed. What kind of fuel filter are you using?

Reserved LN-ENX for Onex #134

Onex build log

Onex build log

- SvingenB

- Posts: 125

- Joined: Tue Oct 08, 2013 5:38 pm

21 posts

• Page 1 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 31 guests