random user submitted photo

Are these good enough?

31 posts

• Page 3 of 4 • 1, 2, 3, 4

Re: Are these good enough?

Sounds like a good/conservative plan, a bit of extra work now to potentially save a lot later.

Ryan Roth

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

-

Rynoth - Posts: 1308

- Joined: Fri Jul 26, 2013 1:32 pm

- Location: Knoxville, TN

Re: Are these good enough?

Here's an update on how I'm going fixing my wing rigging issues.

I removed the forward attach block assemblies off the left wing spar and took them apart in order to replace the attach blocks.

As suspected the 3/8" holes are only enlarged on the forward side of the blocks which means the angles are intact. This is good because this means I could use the existing holes in those to drill the blocks on the drill press, otherwise things would have become more complicated.

Doing this was almost too easy, I first clamped the new blocks to the angles and then drilled the 1/4" holes for the bolts using the holes in the angle as a guide. I then installed those bolts and finally drilled the new 3/8" hole through the blocks again using the hole already present in the angle to position the drill correctly.

Everything was done on the drill press and I could not be more pleased with the results this time.

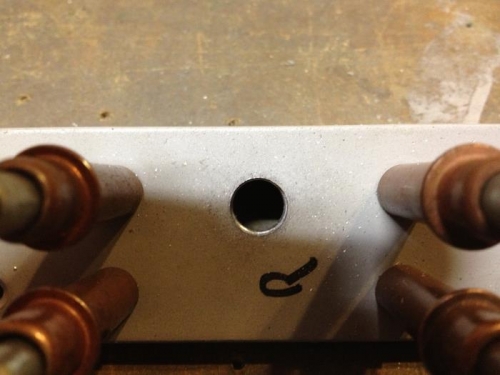

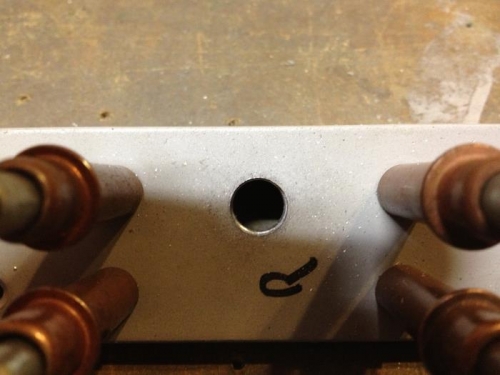

I finally installed the attach block assemblies with the new blocks back on the spar and did various tests and measurements to ensure the holes perfectly straight, round and not enlarged at all.

The bolts need some tapping with a hammer to get in/out of the blocks, this is great, perfect fit!

This was the easy part though, now I need to start on the forward attach angles in the fuselage. I’ve made 2 sets of those, just need to drill out the old broken ones from the fuselage.

The reason I made 2 sets is I have a little experiment I want to do with one set first, using the existing enlarged hole in the existing angles along with a paper-thin bushing as a guide to drill the hole in the new bracket, this I can do on the drill press as well which would mean no more drilling with the wings in place. I will need to but one leg off the old angle so it can be used as a template for drilling all the spar tunnel rivet holes and (on one set) the 3/8" wing pin holes. In theory if everything is still positioned as it was when I messed up my original wing rigging, this should work out.

I'll only cleco that set in place and if it turns out I was not able to get the position of the hole accurate enough, I replace it with the other set and drill the holes from the rear through the wing spars/blocks.

I removed the forward attach block assemblies off the left wing spar and took them apart in order to replace the attach blocks.

As suspected the 3/8" holes are only enlarged on the forward side of the blocks which means the angles are intact. This is good because this means I could use the existing holes in those to drill the blocks on the drill press, otherwise things would have become more complicated.

Doing this was almost too easy, I first clamped the new blocks to the angles and then drilled the 1/4" holes for the bolts using the holes in the angle as a guide. I then installed those bolts and finally drilled the new 3/8" hole through the blocks again using the hole already present in the angle to position the drill correctly.

Everything was done on the drill press and I could not be more pleased with the results this time.

I finally installed the attach block assemblies with the new blocks back on the spar and did various tests and measurements to ensure the holes perfectly straight, round and not enlarged at all.

The bolts need some tapping with a hammer to get in/out of the blocks, this is great, perfect fit!

This was the easy part though, now I need to start on the forward attach angles in the fuselage. I’ve made 2 sets of those, just need to drill out the old broken ones from the fuselage.

The reason I made 2 sets is I have a little experiment I want to do with one set first, using the existing enlarged hole in the existing angles along with a paper-thin bushing as a guide to drill the hole in the new bracket, this I can do on the drill press as well which would mean no more drilling with the wings in place. I will need to but one leg off the old angle so it can be used as a template for drilling all the spar tunnel rivet holes and (on one set) the 3/8" wing pin holes. In theory if everything is still positioned as it was when I messed up my original wing rigging, this should work out.

I'll only cleco that set in place and if it turns out I was not able to get the position of the hole accurate enough, I replace it with the other set and drill the holes from the rear through the wing spars/blocks.

Michael

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

- rizzz

- Posts: 869

- Joined: Tue Jun 21, 2011 2:07 am

- Location: Wollongong, NSW, Australia

Re: Are these good enough?

BTW, I think I now know why my holes got enlarged on the forward side (the side from which you do the final updrilling to 3/8”) got enlarged slightly. SonexAus has a “Wing rigging kit” that gets passed around from builder to builder here in Australia. We used to have a better one (I was told) but that one got lost by Australia Post. The 1/4 - 3/8 piloted drill bit in this kit was donated to us by a kind U.S. builder some time ago but I believe it’s seen its best days. I still have the wing rigging kit at my workshop (nobody is waiting for it at this time) and I did a few test holes with the special bit I find it dances around a bit when the 3/8” part enters the aluminium, well, “dances around” might be a bit exaggerating but it does not seem stable, this gets better as the drill bit goes deeper into the hole.

I decided to order a new drill bit from McMaster which I’ll donate to SonexAus when I’m done with it and arrived yesterday. It seems to handle itself much better BUT, it seems a little short. It’s definitely shorter than the current one included in the Wing rigging kit, I think it will be maybe 1/2" short to go the complete width of the spar tunnel. I think I ordered the same part number everybody else has, have others noticed this one to be a bit short and if so, to you to the last part of the hole just with a normal bit or how does this work?

I decided to order a new drill bit from McMaster which I’ll donate to SonexAus when I’m done with it and arrived yesterday. It seems to handle itself much better BUT, it seems a little short. It’s definitely shorter than the current one included in the Wing rigging kit, I think it will be maybe 1/2" short to go the complete width of the spar tunnel. I think I ordered the same part number everybody else has, have others noticed this one to be a bit short and if so, to you to the last part of the hole just with a normal bit or how does this work?

Michael

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

- rizzz

- Posts: 869

- Joined: Tue Jun 21, 2011 2:07 am

- Location: Wollongong, NSW, Australia

Re: Are these good enough?

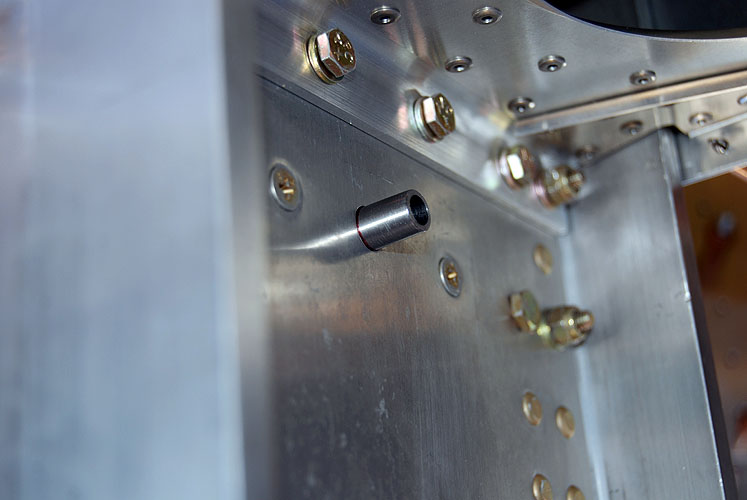

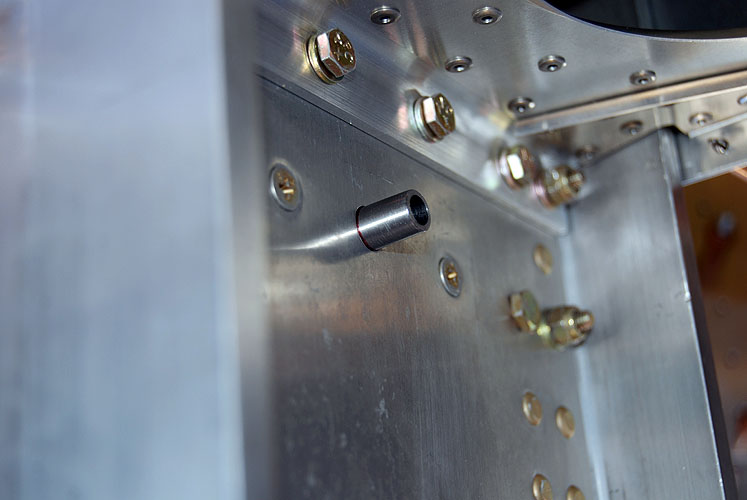

After removing the old forward wing attach angles from the fuselage I cut the side leg off the angles so they could be used as a template to copy the holes that attach them to the spar tunnel.

As you can see in the last picture I've made 2 sets of new forward angles, as mentioned before I will use one set to try and use the enlarged 3/8" hole to drill the new ones in the new angles, I think I'm going to cut up a Coke can to make a small bushing which will allow me to center the 3/8 drill in the enlarged hole. I'm not sure if this will work, the position of the new hole might not fit the hole in the attach blocks precisely, we'll see, if it doesn't work I'll be able to swap the angles with the second set and drill a hole through them from the back of the fuselage.

As you can see in the last picture I've made 2 sets of new forward angles, as mentioned before I will use one set to try and use the enlarged 3/8" hole to drill the new ones in the new angles, I think I'm going to cut up a Coke can to make a small bushing which will allow me to center the 3/8 drill in the enlarged hole. I'm not sure if this will work, the position of the new hole might not fit the hole in the attach blocks precisely, we'll see, if it doesn't work I'll be able to swap the angles with the second set and drill a hole through them from the back of the fuselage.

Michael

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

- rizzz

- Posts: 869

- Joined: Tue Jun 21, 2011 2:07 am

- Location: Wollongong, NSW, Australia

Re: Are these good enough?

I went through a similar problem with my wing rigging. The forward vertical angle and attach block on the right side had a divet in the hole. Left over from the drill not following the pilot hole. I made a bushing to align the good holes to drill the new pilot hole. In the builders log section of my website around 1/21/2014 I have some pictures and narrative if you are interested in what I did. The idea was not mine I had read about it on one of the forums awhile back.

http://stewartaircraft.net/log.php?sub=F02

John Stewart

Sonex 1462

Aerovee, TriGear, Dual Controls

http://stewartaircraft.net

http://stewartaircraft.net/log.php?sub=F02

John Stewart

Sonex 1462

Aerovee, TriGear, Dual Controls

http://stewartaircraft.net

- Sonex1462

- Posts: 135

- Joined: Thu May 16, 2013 8:08 pm

Re: Are these good enough?

Hi All,

I’m happy to say my wing rigging issues are resolved, it set me back about a month but what’s that in the grand scheme of things anyway.

Here’s how things went this weekend.

As mentioned before I'm first trying to copy the existing (enlarged) holes to the first set of the new attach angles so that I don't have to do the scary drilling with the wings installed on the fuselage anymore.

If it doesn't work I have a second set of attach angles with no holes pre-drilled to do it the classic way.

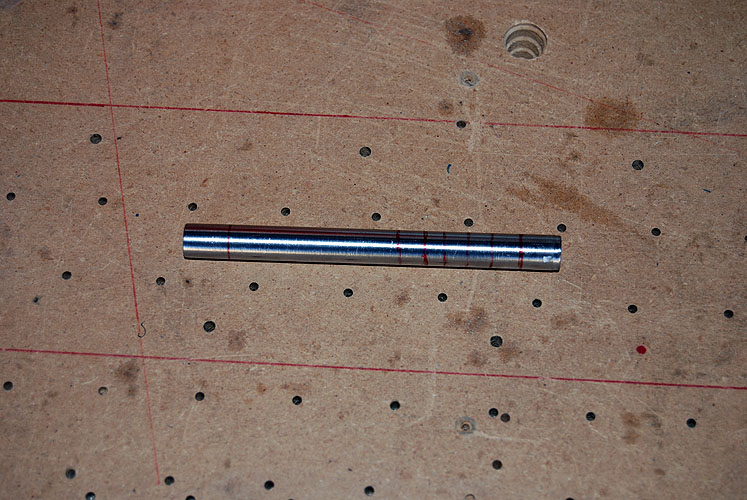

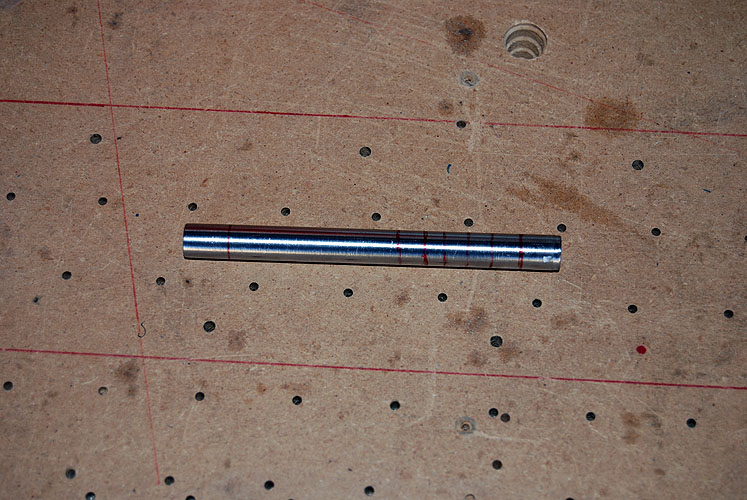

The holes in the old angles were only slightly enlarged, too small to make any sort of bushing from tubes or whatever so I made a bushing from a coke can, cutting it into small strips and rolling one into the enlarged hole. This worked perfectly, I was able to drill a new hole precisely centred in the old enlarged hole.

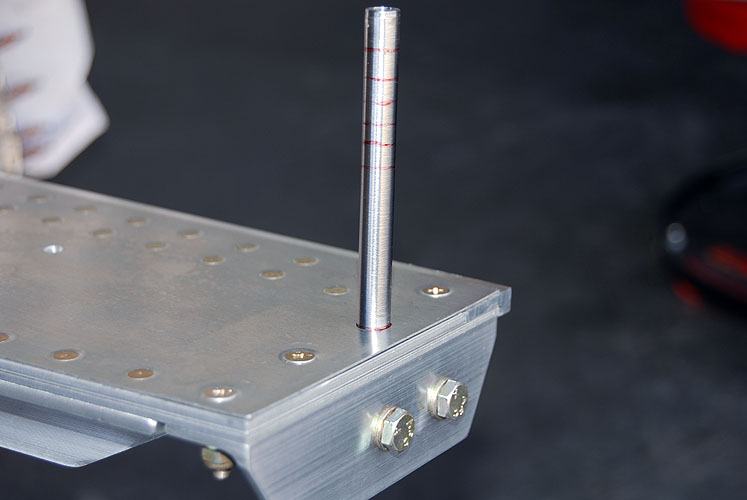

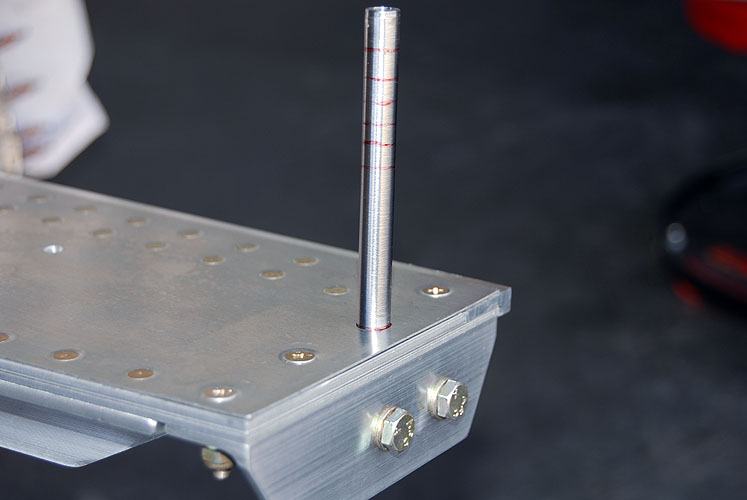

Before I put my wings back onto the fuselage, first I needed to check the spars actually still mate correctly. Remember I took the angles off the spars, attached new blocks and drilled those on the drill press, in theory everything should still be in line but you never know, better to check this before installing them into the fuselage.

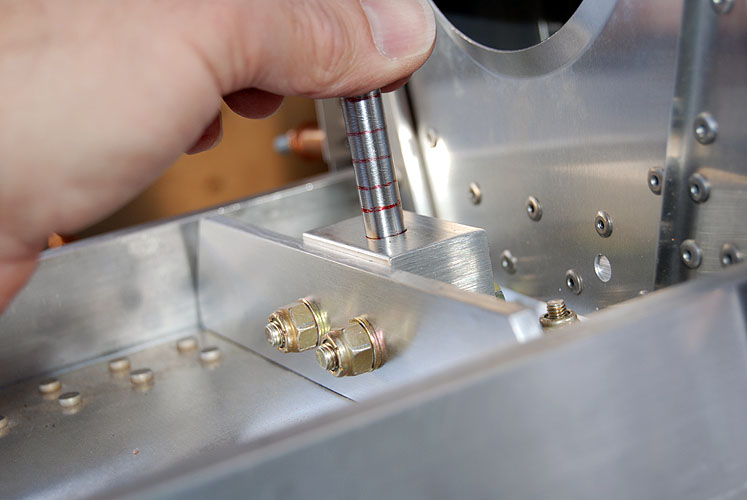

As expected, everything is still in line, the pins need to be tapped in/out with a hammer but that is how it should be. Perfect, so far so good!

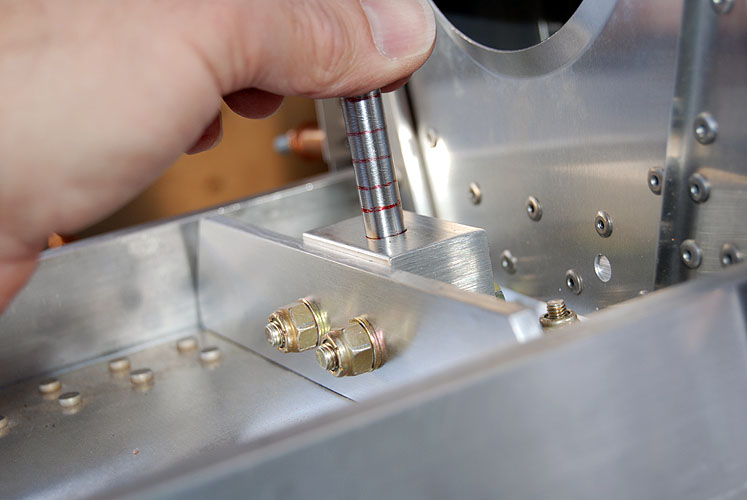

After checking the spars still mate ok, it was time to re-install the wings and hope my experiment with the first set of attach angles so I won't have to do any more drilling.

I had my friend Austin come over to give me a hand installing them again.

And guess what, they fit perfectly, I could not be more pleased with the result, I must say I expected to have to need at least one of the extra angles I made but no, everything matches and lines up.

The pins fit, very, very snug into the holes, a really good result indeed, again I am very happy. I can sleep again! (I've lost quite a bit of sleep over this issue).

After we were done I put the wings in the new stand I made yesterday, looks good and works well.

Also, if you’re wondering about the hitch pins I’m using instead of the AN6 bolts they are a set of 3/8" x 4" hitch pins from McMaster, part number 98497A595. I believe these are the ones Sonex use in their aircraft. When I was talking to Kerry about my rigging issues he said he also had hitch pins in his aircraft. Because they have a tapered tip they are much easier to install than the bolts. They are grade 5 steel (imperial) so should be more than strong enough.

Now, I can finally move on to my panel, wiring and soon after the engine installation.

I’m happy to say my wing rigging issues are resolved, it set me back about a month but what’s that in the grand scheme of things anyway.

Here’s how things went this weekend.

As mentioned before I'm first trying to copy the existing (enlarged) holes to the first set of the new attach angles so that I don't have to do the scary drilling with the wings installed on the fuselage anymore.

If it doesn't work I have a second set of attach angles with no holes pre-drilled to do it the classic way.

The holes in the old angles were only slightly enlarged, too small to make any sort of bushing from tubes or whatever so I made a bushing from a coke can, cutting it into small strips and rolling one into the enlarged hole. This worked perfectly, I was able to drill a new hole precisely centred in the old enlarged hole.

Before I put my wings back onto the fuselage, first I needed to check the spars actually still mate correctly. Remember I took the angles off the spars, attached new blocks and drilled those on the drill press, in theory everything should still be in line but you never know, better to check this before installing them into the fuselage.

As expected, everything is still in line, the pins need to be tapped in/out with a hammer but that is how it should be. Perfect, so far so good!

After checking the spars still mate ok, it was time to re-install the wings and hope my experiment with the first set of attach angles so I won't have to do any more drilling.

I had my friend Austin come over to give me a hand installing them again.

And guess what, they fit perfectly, I could not be more pleased with the result, I must say I expected to have to need at least one of the extra angles I made but no, everything matches and lines up.

The pins fit, very, very snug into the holes, a really good result indeed, again I am very happy. I can sleep again! (I've lost quite a bit of sleep over this issue).

After we were done I put the wings in the new stand I made yesterday, looks good and works well.

Also, if you’re wondering about the hitch pins I’m using instead of the AN6 bolts they are a set of 3/8" x 4" hitch pins from McMaster, part number 98497A595. I believe these are the ones Sonex use in their aircraft. When I was talking to Kerry about my rigging issues he said he also had hitch pins in his aircraft. Because they have a tapered tip they are much easier to install than the bolts. They are grade 5 steel (imperial) so should be more than strong enough.

Now, I can finally move on to my panel, wiring and soon after the engine installation.

Michael

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

- rizzz

- Posts: 869

- Joined: Tue Jun 21, 2011 2:07 am

- Location: Wollongong, NSW, Australia

Are these good enough?

Excellent news!

I have been following your posts closely as I am weeks away from this...

Congratulations.

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

I have been following your posts closely as I am weeks away from this...

Congratulations.

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

Robbie Culver

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

-

Sonex1517 - Posts: 1670

- Joined: Fri Jun 03, 2011 10:11 am

- Location: T25 Aero Estates, Frankston, TX

Re: Are these good enough?

Hooray!

Ryan Roth

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

-

Rynoth - Posts: 1308

- Joined: Fri Jul 26, 2013 1:32 pm

- Location: Knoxville, TN

Re: Are these good enough?

2 victories here Micheal. Getting McMaster Carr to ship outside the States is almost as difficult as rigging the wings. ;)

Well done.

Steve

Sonex 892

Well done.

Steve

Sonex 892

- sonex892

- Posts: 169

- Joined: Fri Jun 03, 2011 4:49 am

- Location: Port Macquarie Australia

Re: Are these good enough?

sonex892 wrote:2 victories here Micheal. Getting McMaster Carr to ship outside the States is almost as difficult as rigging the wings. ;)

Well done.

Steve

Sonex 892

Thanks Steve,

I use MyUS (http://www.myus.com/) to order stuff from suppliers in the U.S. that won’t ship to Australia.

They give you an address in the U.S. that suppliers ship to, they will forward from there.

It’s cheap, easy to use, and they’ve got pretty good shipping rates with DHL as well.

Also, if you’re ordering from multiple suppliers you can ask them to hold on to your items until they’ve received them all and then send them in one package. You can save heaps on shipping costs that way.

Michael

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

- rizzz

- Posts: 869

- Joined: Tue Jun 21, 2011 2:07 am

- Location: Wollongong, NSW, Australia

31 posts

• Page 3 of 4 • 1, 2, 3, 4

Who is online

Users browsing this forum: No registered users and 103 guests