random user submitted photo

Revmaster 2100-D: Oil Catch Can Filling Up Quickly

4 posts

• Page 1 of 1

Revmaster 2100-D: Oil Catch Can Filling Up Quickly

Hi all,

I am new to the forums and just purchased Sonex N541SX. For the 10 hrs I've flown her, she's been an absolute blast! However I am having engine oil problems where the aircraft is throwing a substantial amount of oil out of the breather, and I do mean substantial. Drained the oil catch can 2 days ago and have flown 2.6 hours since and it is now completely full of dark looking oil.

Today for instance I took off, flew for an hour, and upon landing had gone from having full oil to being at the min fill line on the dipstick and an oil pressure reading of 28psi (took off with it at between 50-60psi).

I am very concerned as to what is causing such a substantial amount of oil to be thrown out of the breather tube. I have inspected the entire engine exterior to verify that there are no other leaks.The aircraft's belly is also very oily which to me indicates that the breather is the culprit. As to what is making the breather throw out all this oil has yet to be determined.

Has anyone else with a Revmaster Engine or an Aerovee had a similar issue? Currently in contact with Joe Horvath at Revmaster for technical help and possible troubleshooting steps to determine root cause and correction.

I am new to the forums and just purchased Sonex N541SX. For the 10 hrs I've flown her, she's been an absolute blast! However I am having engine oil problems where the aircraft is throwing a substantial amount of oil out of the breather, and I do mean substantial. Drained the oil catch can 2 days ago and have flown 2.6 hours since and it is now completely full of dark looking oil.

Today for instance I took off, flew for an hour, and upon landing had gone from having full oil to being at the min fill line on the dipstick and an oil pressure reading of 28psi (took off with it at between 50-60psi).

I am very concerned as to what is causing such a substantial amount of oil to be thrown out of the breather tube. I have inspected the entire engine exterior to verify that there are no other leaks.The aircraft's belly is also very oily which to me indicates that the breather is the culprit. As to what is making the breather throw out all this oil has yet to be determined.

Has anyone else with a Revmaster Engine or an Aerovee had a similar issue? Currently in contact with Joe Horvath at Revmaster for technical help and possible troubleshooting steps to determine root cause and correction.

- Attachments

Byron Custer

Legacy Sonex N541SX (Conventional Gear)

Revmaster 2100-D

Legacy Sonex N541SX (Conventional Gear)

Revmaster 2100-D

- Aerotechnic

- Posts: 2

- Joined: Tue Jan 10, 2023 9:37 pm

Re: Revmaster 2100-D: Oil Catch Can Filling Up Quickly

Check out this thread, in particular the last 4 or 5 pages. I had a lot going out the breather, and I rigged up an air-oil separator which returns oil back to the valve cover. Took some iterations but I'm pretty happy with it now. I maybe need to add 1/2 quart over the 25 hour oil change. Some portion of that is leaks.

viewtopic.php?f=7&t=4030

Welcome to the forum!

viewtopic.php?f=7&t=4030

Welcome to the forum!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Revmaster 2100-D: Oil Catch Can Filling Up Quickly

So, its been a couple months....

However, the oil issue I'm having still persists. I estimate that the engine blows a quart of oil every hour, which is completely unsustainable. This oil all gets expelled out the breather tube and ends up as black oil in my oil catch can. Since my initial post, I have performed a leak down test with the lowest compression being 69/80 in cylinder 2 (all the others were 72/80) and a compression test that showed cylinder 2 having 160psi compression that increased to 170 when oil was added to the cylinder.

I also bore-scoped the cylinders and discovered metal chips on the walls of cylinder 2 that I believe to be from the piston rings which would at first indicate that cylinder 2's piston rings are what is causing my problems. I have included a picture from this inspection that shows these chips inside the cylinder and on the piston.

However, I am quick to call this the smoking gun. How can it be that both the compression and leak down tests show such high values, yet there is such an immense amount of blow-by? All the other cylinders that I bore-scoped were fine, their leak down and compression values were solid, and there are no other signs of damage or fault in the engine that I can see. Obviously the piston ring or something else in cylinder 2 needs replaced (metal flakes make that pretty obvious haha) but I still am not entirely convinced that this is the solution to my problem.

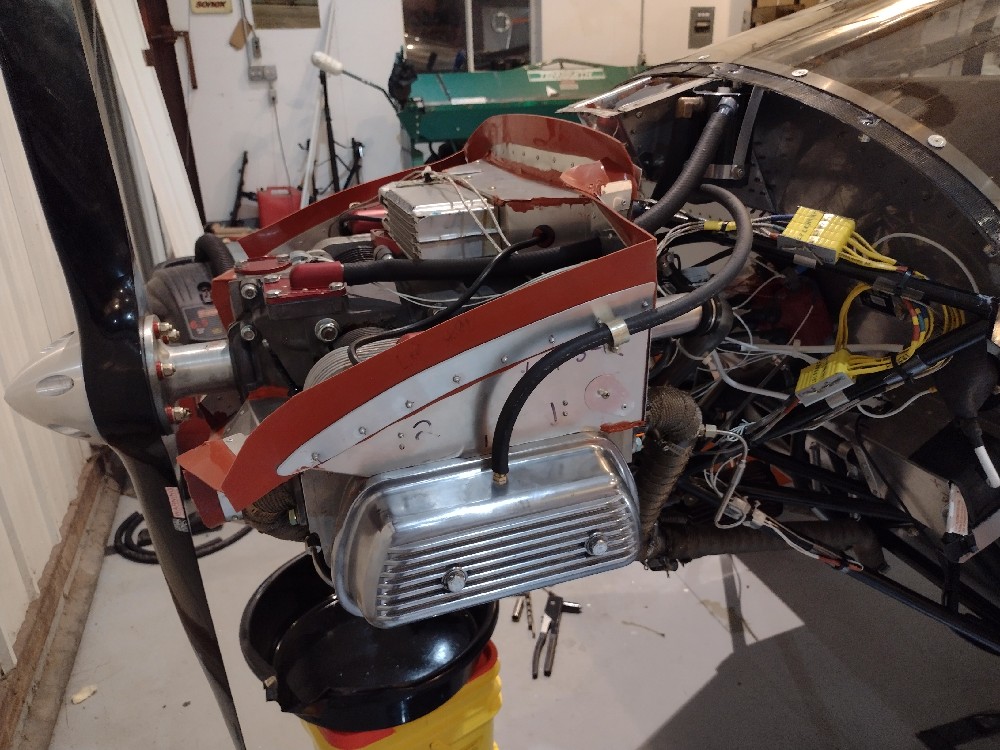

It's also worth mentioning that at the outlet to the breather, there is a copper mesh ball that acts as an air oil separator for the engine. Nominally, it works very well at stopping oil from exiting the crank case, but as of now, a significant amount still manages to make it past while the aircraft is flying. Below is a picture to show it with the cover removed sitting in the engine.

Any further suggestions to help fix this problem would be highly welcomed. As of now it looks like I'm about to yank the heads off and see what I find.

However, the oil issue I'm having still persists. I estimate that the engine blows a quart of oil every hour, which is completely unsustainable. This oil all gets expelled out the breather tube and ends up as black oil in my oil catch can. Since my initial post, I have performed a leak down test with the lowest compression being 69/80 in cylinder 2 (all the others were 72/80) and a compression test that showed cylinder 2 having 160psi compression that increased to 170 when oil was added to the cylinder.

I also bore-scoped the cylinders and discovered metal chips on the walls of cylinder 2 that I believe to be from the piston rings which would at first indicate that cylinder 2's piston rings are what is causing my problems. I have included a picture from this inspection that shows these chips inside the cylinder and on the piston.

However, I am quick to call this the smoking gun. How can it be that both the compression and leak down tests show such high values, yet there is such an immense amount of blow-by? All the other cylinders that I bore-scoped were fine, their leak down and compression values were solid, and there are no other signs of damage or fault in the engine that I can see. Obviously the piston ring or something else in cylinder 2 needs replaced (metal flakes make that pretty obvious haha) but I still am not entirely convinced that this is the solution to my problem.

It's also worth mentioning that at the outlet to the breather, there is a copper mesh ball that acts as an air oil separator for the engine. Nominally, it works very well at stopping oil from exiting the crank case, but as of now, a significant amount still manages to make it past while the aircraft is flying. Below is a picture to show it with the cover removed sitting in the engine.

Any further suggestions to help fix this problem would be highly welcomed. As of now it looks like I'm about to yank the heads off and see what I find.

Byron Custer

Legacy Sonex N541SX (Conventional Gear)

Revmaster 2100-D

Legacy Sonex N541SX (Conventional Gear)

Revmaster 2100-D

- Aerotechnic

- Posts: 2

- Joined: Tue Jan 10, 2023 9:37 pm

Re: Revmaster 2100-D: Oil Catch Can Filling Up Quickly

I had a cylinder in my Aerovee do the same thing. The clue is the spark plug in that cylinder fouled with oil. The cylinder was pumping oil due to a broken oil ring. After pulling the head and cylinder I found the oil ring, which is supported by a spring underneath, had small upturned ends which were supposed to stop it from over lapping the ends. One of the turned up ends was broken off. The new set of rings had molded plastic ends on the oil ring that were color coded with instructions that said to be sure you could see the green end when inserting the piston into the the cylinder. Problem solved.

OneX 107

N2107X

N2107X

- Onex107

- Posts: 506

- Joined: Mon Mar 24, 2014 6:44 pm

- Location: Peoria, IL

4 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 17 guests