random user submitted photo

The demise of my engine

15 posts

• Page 1 of 2 • 1, 2

The demise of my engine

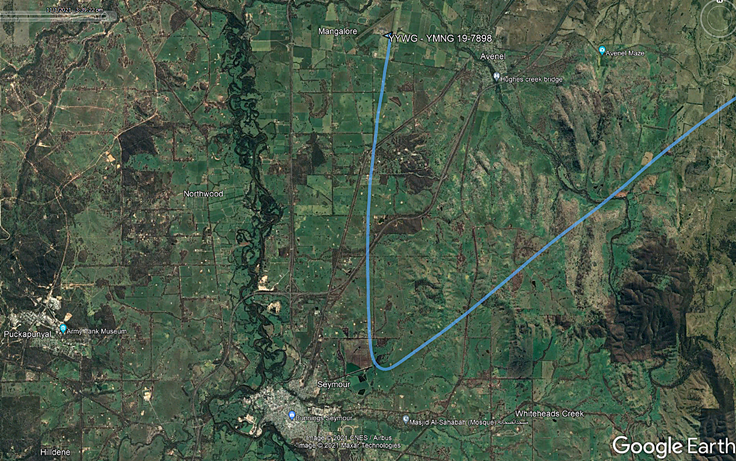

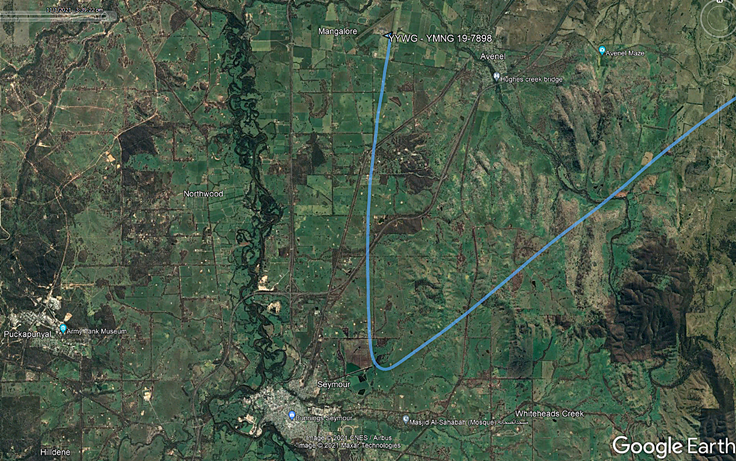

I had my first ever forced landing while taking my grandson for a flight. If you are going to have a forced landing, I highly recommend having it within gliding distance of a large airfield.

By chance we were within gliding range of Mangalore airfield so the airframe is intact but my engine is toast.

The cause of all the damage, a broken exhaust valve. I have plenty more to say on it. If you'd like to read the details, here's a link to my website: http://www.ansoneng.com/sample-page/other-stuff-of-interest/the-demise-of-my-engine/

Peter

By chance we were within gliding range of Mangalore airfield so the airframe is intact but my engine is toast.

The cause of all the damage, a broken exhaust valve. I have plenty more to say on it. If you'd like to read the details, here's a link to my website: http://www.ansoneng.com/sample-page/other-stuff-of-interest/the-demise-of-my-engine/

Peter

- peter anson

- Posts: 558

- Joined: Thu Jul 31, 2014 2:34 am

- Location: Mount Macedon, Australia

Re: The demise of my engine

Wow! I am very glad that ended well Peter! Great job!

Robbie Culver

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

-

Sonex1517 - Posts: 1670

- Joined: Fri Jun 03, 2011 10:11 am

- Location: T25 Aero Estates, Frankston, TX

Re: The demise of my engine

Congratulations, Peter, on keeping your cool and having a successful outcome. Having the same vintage 3300 engine as yours, I was most interested in reading your detailed report. Question for you: prior to the #5 cylinder exhaust valve failure, say the previous 5 to 10 hours, had you noticed any relatively subtle increase in the vibration level of your engine? I ask because I believe I may be detecting a small increase in vibration in my engine. Searching for external causes or even internal causes that may be picked up with a scope of each cylinder, I find nothing. I do have a spare set of new valves on the shelf. Maybe it's time to install them.

Thanks for any insight you may have,

Art,,,,,,,,,,,,,,,,,,,,Sonex taildragger #95,,,,,,,,,,,,,,,,,,,Jabiru 3300 #261 (800 hours, original valves)

Thanks for any insight you may have,

Art,,,,,,,,,,,,,,,,,,,,Sonex taildragger #95,,,,,,,,,,,,,,,,,,,Jabiru 3300 #261 (800 hours, original valves)

- builderflyer

- Posts: 441

- Joined: Sat Jul 09, 2016 12:13 pm

Re: The demise of my engine

Peter,

It's great to hear that you and your grandson are safe. So fortunate to be near an airfield and have 5 minutes of glide time. It also speaks to your piloting skill. Thank you for your detailed write up so we can all learn from what your engine experienced.

Best,

Paul

It's great to hear that you and your grandson are safe. So fortunate to be near an airfield and have 5 minutes of glide time. It also speaks to your piloting skill. Thank you for your detailed write up so we can all learn from what your engine experienced.

Best,

Paul

- thomas

- Posts: 59

- Joined: Sat Aug 27, 2016 9:45 am

Re: The demise of my engine

builderflyer wrote:Congratulations, Peter, on keeping your cool and having a successful outcome. Having the same vintage 3300 engine as yours, I was most interested in reading your detailed report. Question for you: prior to the #5 cylinder exhaust valve failure, say the previous 5 to 10 hours, had you noticed any relatively subtle increase in the vibration level of your engine? I ask because I believe I may be detecting a small increase in vibration in my engine. Searching for external causes or even internal causes that may be picked up with a scope of each cylinder, I find nothing. I do have a spare set of new valves on the shelf. Maybe it's time to install them.

Thanks for any insight you may have,

Art,,,,,,,,,,,,,,,,,,,,Sonex taildragger #95,,,,,,,,,,,,,,,,,,,Jabiru 3300 #261 (800 hours, original valves)

Absolutely no warning whatsoever Art, which is not surprising with a fatigue failure. I still have to disassemble three heads. I'm intending to section a couple of the valves and the broken stem and have a look at them with a metallurgical microscope but that won't happen until I get a bit of spare time. Fatigue cracks usually start from some sort of flaw, and my best guess is a surface pit. It might be that some sort of pit is more likely to form at high temperatures. I thought I might have found a possible clue. I had just done the 25 hour service and found all the valve clearances on the right side of the engine tight. I put it down at the time to things settling in after the engine reassembly, but after the failure I pulled all the right side valves out expecting to find cracks, but nothing.

Peter

- peter anson

- Posts: 558

- Joined: Thu Jul 31, 2014 2:34 am

- Location: Mount Macedon, Australia

Re: The demise of my engine

Peter, others, in the e-manual written by Roger Lewis and entitled "The Jabiru Engine: Cylinder Head Service and Overhaul", Lewis says that when inspecting the valves, that cleaning the valve stems can mask cracks. He goes on to describe a technique to sandblast the valve stems in a certain way to make any possible cracks visible. Lewis also goes on to say that the valves in a Jabiru engine need to be lapped-in every 300 hours. I haven't followed any of Lewis's recommendation in maintaining my engine, probably few do, but I can see where if we did what he suggests, there would likely never be a valve failure.

For what's it's worth,

Art,,,,,,,,,,,,,,,,,,,Sonex taildragger #95,,,,,,,,,,,,,,,,,,,,Jabiru 3300 #261

For what's it's worth,

Art,,,,,,,,,,,,,,,,,,,Sonex taildragger #95,,,,,,,,,,,,,,,,,,,,Jabiru 3300 #261

- builderflyer

- Posts: 441

- Joined: Sat Jul 09, 2016 12:13 pm

Re: The demise of my engine

Wow peter,

glad you got down ok! i was always under the opinion to replace exhaust valves anytime the engine being rebuilt.

Due to the added heat and stress of combustion.

I was flying a C-152 about 32 yrs ago now, over lake winnebago just north of fond du lac.wi.

A loud bang happened with good vibration and loss of rpm but engine still running, partial power.

i didnt touch the throttle , as the engine continued to run.

made a direct path to rwy 18 at KFLD . announced a mayday on unicom and asked other planes to clear a path.

i eeked out a little climb, flew a military overhead pattern , over the numbers rwy 18 reduced pwr, and rt break,came

in for landing which was assured even if the engine quit. landed and pulled the mixture. Did my best bob hoover

act with a rollout to the ramp in front of fbo. got out and ran for the self fuel island for the fire extingusher.

came back, saw lots of oil dripping and oil smoke. plane put in hangar. monday morning the mechanics pulled the cowl

and engine cylinder.. an exhaust valve head broke off, lyc O-235. it imbeded itself vertically in the piston, which then broke out a section of the cylinder head. a new cylinder and piston was installed and the plane was flying again in a few days.

looks like you had the exhaust valve head rattle around in the cylinder and trashed other components of the motor.

sorry to see. glad you got it down safe.

whats your next plan for a motor?

WaiexN143NM

Michael

glad you got down ok! i was always under the opinion to replace exhaust valves anytime the engine being rebuilt.

Due to the added heat and stress of combustion.

I was flying a C-152 about 32 yrs ago now, over lake winnebago just north of fond du lac.wi.

A loud bang happened with good vibration and loss of rpm but engine still running, partial power.

i didnt touch the throttle , as the engine continued to run.

made a direct path to rwy 18 at KFLD . announced a mayday on unicom and asked other planes to clear a path.

i eeked out a little climb, flew a military overhead pattern , over the numbers rwy 18 reduced pwr, and rt break,came

in for landing which was assured even if the engine quit. landed and pulled the mixture. Did my best bob hoover

act with a rollout to the ramp in front of fbo. got out and ran for the self fuel island for the fire extingusher.

came back, saw lots of oil dripping and oil smoke. plane put in hangar. monday morning the mechanics pulled the cowl

and engine cylinder.. an exhaust valve head broke off, lyc O-235. it imbeded itself vertically in the piston, which then broke out a section of the cylinder head. a new cylinder and piston was installed and the plane was flying again in a few days.

looks like you had the exhaust valve head rattle around in the cylinder and trashed other components of the motor.

sorry to see. glad you got it down safe.

whats your next plan for a motor?

WaiexN143NM

Michael

- WaiexN143NM

- Posts: 1206

- Joined: Mon Sep 15, 2014 1:04 am

- Location: palm springs CA

Re: The demise of my engine

hi peter,

also curious , where is the head of that valve? did it bust thru the piston and in the case sump ?

WaiexN143NM

Michael

also curious , where is the head of that valve? did it bust thru the piston and in the case sump ?

WaiexN143NM

Michael

- WaiexN143NM

- Posts: 1206

- Joined: Mon Sep 15, 2014 1:04 am

- Location: palm springs CA

Re: The demise of my engine

Valve head and rest of piston presumably in the sump or embedded in the crankcase. Incidentally, bits of debris up to a couple of millimetres got into the intake manifold and even into other cylinders.

I have a gen 4 engine on order but waiting time is 6 months. Obviously I have a few reservations but I no longer have the workshop space to make major changes.

Peter

I have a gen 4 engine on order but waiting time is 6 months. Obviously I have a few reservations but I no longer have the workshop space to make major changes.

Peter

- peter anson

- Posts: 558

- Joined: Thu Jul 31, 2014 2:34 am

- Location: Mount Macedon, Australia

Re: The demise of my engine

All,

Could I respectfully again(!) point out that you have NO IDEA about your maximum egt’s!

The instrument shows an avarage value in a process cycle. To get 720C’s as an average, you’re likely to exceed the 800 mark as a top- which is excessive in anybody’s language. The only thing common instrumentation like we usually install could provide, is an eventual change from previous readings given that it is precise enough to pick up small variations: deviations from older readings.

Many of them are not. And a good sender/instrument combo could have an error of 25C’s- the low quality stuff probably more.

The precise way to monitor the combustion process, is to weld on a bung on each cylinder exhaust outlet pipe and stick in oxygen sensors, connected to an Air/Fuel ratio gage. Yes- I know: costs a small fortune :-(

Could minuscule traces of burnt oil be detected at the bottom of the cylinder/head sealing surface? If so, there has been a leak. A leak will invariably result in a leaner running cylinder: not good! Your already struggling exhaust valve is suddenly looking at en early demise. And the leak itself is the result of inefficient cooling. Problem is, the head is often insufficiently cooled around the bottom bolt, notwithstandin the fact that the cht sensor up there close to the spark plug (where it benefits from lots of cooling air!) provides reassuring readings. This will gradually result in the aluminium loosing its temper (going ‘plastic’ is a popular expression), the head bolt looses its pretension- and voilà: gremlins are at work to ruin your flight.

Somehow the cooling air must also be forced to cool this lower half of the head: a lot of cool air is needed over the fins down there. Unless, of course, you could come up with something better!

Could I respectfully again(!) point out that you have NO IDEA about your maximum egt’s!

The instrument shows an avarage value in a process cycle. To get 720C’s as an average, you’re likely to exceed the 800 mark as a top- which is excessive in anybody’s language. The only thing common instrumentation like we usually install could provide, is an eventual change from previous readings given that it is precise enough to pick up small variations: deviations from older readings.

Many of them are not. And a good sender/instrument combo could have an error of 25C’s- the low quality stuff probably more.

The precise way to monitor the combustion process, is to weld on a bung on each cylinder exhaust outlet pipe and stick in oxygen sensors, connected to an Air/Fuel ratio gage. Yes- I know: costs a small fortune :-(

Could minuscule traces of burnt oil be detected at the bottom of the cylinder/head sealing surface? If so, there has been a leak. A leak will invariably result in a leaner running cylinder: not good! Your already struggling exhaust valve is suddenly looking at en early demise. And the leak itself is the result of inefficient cooling. Problem is, the head is often insufficiently cooled around the bottom bolt, notwithstandin the fact that the cht sensor up there close to the spark plug (where it benefits from lots of cooling air!) provides reassuring readings. This will gradually result in the aluminium loosing its temper (going ‘plastic’ is a popular expression), the head bolt looses its pretension- and voilà: gremlins are at work to ruin your flight.

Somehow the cooling air must also be forced to cool this lower half of the head: a lot of cool air is needed over the fins down there. Unless, of course, you could come up with something better!

Sonex A #0525- SG, DS.

EdgePerfomance EP915ECI, 123HP

EdgePerfomance EP915ECI, 123HP

- Kai

- Posts: 305

- Joined: Wed Jul 30, 2014 1:36 am

- Location: ICAO ENHS

15 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 14 guests