random user submitted photo

Alternate Baffle Seal

15 posts

• Page 1 of 2 • 1, 2

Alternate Baffle Seal

All -

Like many others I've had a dickens of a time with the default rubber seal material supplied with the kit - it is *so* hard and unyielding that I cannot get the baffles trimmed to a good level that allow for sealing without requiring so much force that the fiberglass cowling distorts. The rigid leg of the "D" seems to really resist compression! I've re-trimmed my fence baffles 3 or 4 times trying to find the "sweet spot", but still can't get a good compromise of consistent sealing while allowing the cowling to sit (or be pulled down with fasteners) without major distortion.

Anyone have thoughts on this alternate seal available at McMaster-Carr Aerospace?

https://www.mcmaster.com/9141K117

This version of the "D" or "P" shaped baffle seal is much more pliable. If it was barely contacting the cowling on the inside then I'd be worried about it "blowing out" under pressure and allowing the air to leak past the top of the engine instead of being directed down through the cylinders; but if its compressed quite a bit (i.e. your baffle itself is within a quarter-inch of the cowling) then the thick foam compresses down strongly and seems like it'll hold.

The major downside is that this material is only rated up to 350 degrees F. On the one hand, that seems low compared to most engine compartment items. On the other hand, if something in contact with the fiberglass cowling is 350 degrees, the cowling itself will be melting already, right? CHT redline is 450, and realistically you probably don't want it above 380 or so for any length of time (per Mike Bush) and the baffle seals are several inches away from the heads... so they shouldn't get anywhere near that hot in normal ops, right?

Anyone have thoughts; or any actual measurements of under-cowling temps after shutdown (with the attendant heat-soak)?

--Noel

Like many others I've had a dickens of a time with the default rubber seal material supplied with the kit - it is *so* hard and unyielding that I cannot get the baffles trimmed to a good level that allow for sealing without requiring so much force that the fiberglass cowling distorts. The rigid leg of the "D" seems to really resist compression! I've re-trimmed my fence baffles 3 or 4 times trying to find the "sweet spot", but still can't get a good compromise of consistent sealing while allowing the cowling to sit (or be pulled down with fasteners) without major distortion.

Anyone have thoughts on this alternate seal available at McMaster-Carr Aerospace?

https://www.mcmaster.com/9141K117

This version of the "D" or "P" shaped baffle seal is much more pliable. If it was barely contacting the cowling on the inside then I'd be worried about it "blowing out" under pressure and allowing the air to leak past the top of the engine instead of being directed down through the cylinders; but if its compressed quite a bit (i.e. your baffle itself is within a quarter-inch of the cowling) then the thick foam compresses down strongly and seems like it'll hold.

The major downside is that this material is only rated up to 350 degrees F. On the one hand, that seems low compared to most engine compartment items. On the other hand, if something in contact with the fiberglass cowling is 350 degrees, the cowling itself will be melting already, right? CHT redline is 450, and realistically you probably don't want it above 380 or so for any length of time (per Mike Bush) and the baffle seals are several inches away from the heads... so they shouldn't get anywhere near that hot in normal ops, right?

Anyone have thoughts; or any actual measurements of under-cowling temps after shutdown (with the attendant heat-soak)?

--Noel

- NWade

- Posts: 527

- Joined: Mon Aug 08, 2011 3:58 pm

Re: Alternate Baffle Seal

Noel,

I can't answer your question on the D seal but here is an alternative solution that I used when I ran into the baffle seal difficulty way back when I was building my RV6. I started cutting rubber for the seals on a Saturday morning and soon realized that I needed 19 pieces and getting all to seal 100% didn't seem likely. So I switched gears, dug out some scrap extruded poly foam and put it between the aluminum baffles around the engine. Less than an hour with a surform plane and sandpaper, the shape was done where it just fit under the cowling. I taped on some Seran Wrap, mixed up some old Safetypoxy and laid on about four plies of 6 oz, Eglass, with more around the edges. By the end of the day, the resin was set up enough to remove it to get the foam out, trim the edges where needed, and push the laminate back in position for a tight fit onto the baffles for a full cure overnight. Yep, one day to make the plenum and rid the hassle of fitting rubber seals. But it took the rest of the next week of evening work sessions to fit the rubber strips to the top cowling to seal the inlet to the plenum.

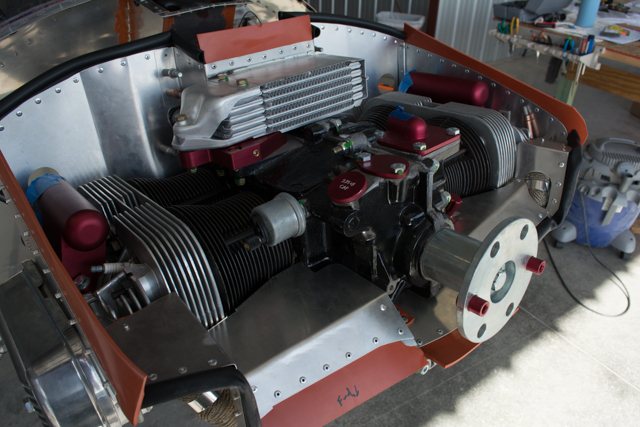

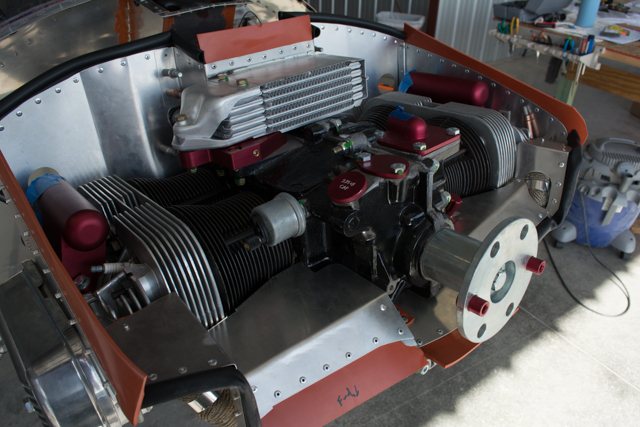

That was done in 1999 and I now have 1011 hrs on it. This is a picture from last month during the annual inspection (prop overhaul, etc.) and the engine temps have not bothered the plenum materials. My Lycoming in an RV6 cowl runs in the 400-425 F range so it is hotter than what you will see. My recommendation is to make a plenum. Also keeps the forces on the cowl to a minimum.

Rick Caldwell

Xenos 0057

I can't answer your question on the D seal but here is an alternative solution that I used when I ran into the baffle seal difficulty way back when I was building my RV6. I started cutting rubber for the seals on a Saturday morning and soon realized that I needed 19 pieces and getting all to seal 100% didn't seem likely. So I switched gears, dug out some scrap extruded poly foam and put it between the aluminum baffles around the engine. Less than an hour with a surform plane and sandpaper, the shape was done where it just fit under the cowling. I taped on some Seran Wrap, mixed up some old Safetypoxy and laid on about four plies of 6 oz, Eglass, with more around the edges. By the end of the day, the resin was set up enough to remove it to get the foam out, trim the edges where needed, and push the laminate back in position for a tight fit onto the baffles for a full cure overnight. Yep, one day to make the plenum and rid the hassle of fitting rubber seals. But it took the rest of the next week of evening work sessions to fit the rubber strips to the top cowling to seal the inlet to the plenum.

That was done in 1999 and I now have 1011 hrs on it. This is a picture from last month during the annual inspection (prop overhaul, etc.) and the engine temps have not bothered the plenum materials. My Lycoming in an RV6 cowl runs in the 400-425 F range so it is hotter than what you will see. My recommendation is to make a plenum. Also keeps the forces on the cowl to a minimum.

Rick Caldwell

Xenos 0057

- racaldwell

- Posts: 400

- Joined: Thu May 22, 2014 4:52 pm

Re: Alternate Baffle Seal

I went with this when building my plane:

https://www.aircraftspruce.com/catalog/ ... ckkey=3611

I trimmed the metal baffles about a 1/2" short of reaching the cowling and then left about 1.25" of the baffle material sticking out above that. I ran it all the way around in one continuous piece from the front of the cowling, across the back, and back to the front on the other side. It is held on with rivets and backing strips made from aluminum. After 100 hours of flying it is holding up well. The material folds inward when I put the top cowling on so the harder the air blows the tighter the seal gets against the cowl. I think I had the baffles trimmed and the seal installed in about 2 nights worth of work. It seemed much easier than trying to get a perfect trim with the p-seal.

Keith

#554

https://www.aircraftspruce.com/catalog/ ... ckkey=3611

I trimmed the metal baffles about a 1/2" short of reaching the cowling and then left about 1.25" of the baffle material sticking out above that. I ran it all the way around in one continuous piece from the front of the cowling, across the back, and back to the front on the other side. It is held on with rivets and backing strips made from aluminum. After 100 hours of flying it is holding up well. The material folds inward when I put the top cowling on so the harder the air blows the tighter the seal gets against the cowl. I think I had the baffles trimmed and the seal installed in about 2 nights worth of work. It seemed much easier than trying to get a perfect trim with the p-seal.

Keith

#554

- kmacht

- Posts: 772

- Joined: Tue Jun 21, 2011 11:30 am

Re: Alternate Baffle Seal

racaldwell wrote:Noel,

I can't answer your question on the D seal but here is an alternative solution that I used ...

Nicely done! This is the way to go I think. How complicated is it to remove/install when needing access to the engine?

- lutorm

- Posts: 259

- Joined: Mon May 15, 2017 1:35 pm

- Location: The Island of Hawai

Re: Alternate Baffle Seal

It does look nice. How much does it weigh?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Alternate Baffle Seal

To answer your questions, there are 18 screws to unscrew to remove the plenum. With a screwgun, maybe 2-3 minutes to remove. The screws have nutplates (#8) and are SS.

I haven't weighed the plenum. I would guess maybe 1 lb. It's not much. The rubber baffle seals weigh much more. Those are sitting in the junk cabinet in the back of the hangar.

I will be doing this again when the time comes for my CAMit 3300 installation.

Rick Caldwell

Xenos 0057

I haven't weighed the plenum. I would guess maybe 1 lb. It's not much. The rubber baffle seals weigh much more. Those are sitting in the junk cabinet in the back of the hangar.

I will be doing this again when the time comes for my CAMit 3300 installation.

Rick Caldwell

Xenos 0057

- racaldwell

- Posts: 400

- Joined: Thu May 22, 2014 4:52 pm

Re: Alternate Baffle Seal

I used the product Keith linked for much of my baffle seal, and ended up with a combination of both seals.

The Sonex-provided "D" seal worked well enough when it was perpendicular contact with the cowling, but I liked the wider/softer (orange) silicon flap seal where it met the cowling at an angle, and/or where the gaps between baffle and cowling were larger than ~1/2 inch.

The Sonex-provided "D" seal worked well enough when it was perpendicular contact with the cowling, but I liked the wider/softer (orange) silicon flap seal where it met the cowling at an angle, and/or where the gaps between baffle and cowling were larger than ~1/2 inch.

Ryan Roth

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

-

Rynoth - Posts: 1308

- Joined: Fri Jul 26, 2013 1:32 pm

- Location: Knoxville, TN

Re: Alternate Baffle Seal

My roll of baffle material weighs 0.814 lbs.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Alternate Baffle Seal

Yep, same problems here...solved with the red baffle seal from ACS...see page 16 on the photo album Darick's Sonex...

I also noticed the factory seal, which I kept in place at the sides and front, and have come in contact with oil, have become sticky, soft, gooie which is a sign of incompatibility with oil. I suspect it may be EPDM rubber (ethelyene propolyene) used mainly for water exposure. Silicone rubber, the red stuff sold by ACS for baffle seal, has the best qualities for heat and oil resistance.

Not to blow my own horn but, my work experience for 30 years in the fluid power business was solving problems with sealing devices made of all kinds of rubber and plastics...buna/nitrile, viton, Teflon, nylon, etc.

I also noticed the factory seal, which I kept in place at the sides and front, and have come in contact with oil, have become sticky, soft, gooie which is a sign of incompatibility with oil. I suspect it may be EPDM rubber (ethelyene propolyene) used mainly for water exposure. Silicone rubber, the red stuff sold by ACS for baffle seal, has the best qualities for heat and oil resistance.

Not to blow my own horn but, my work experience for 30 years in the fluid power business was solving problems with sealing devices made of all kinds of rubber and plastics...buna/nitrile, viton, Teflon, nylon, etc.

Darick Gundy

Sonex #1646

N417DG

Taildragger, Aerovee, center stick, Prince P-Tip Prop

MGL E1, F2, V6 radio, Sandia Xponder, Reserve lift indicator (AOA), iFly 520

First flight! 10/21/2017

Sonex #1646

N417DG

Taildragger, Aerovee, center stick, Prince P-Tip Prop

MGL E1, F2, V6 radio, Sandia Xponder, Reserve lift indicator (AOA), iFly 520

First flight! 10/21/2017

-

Darick - Posts: 496

- Joined: Mon Aug 05, 2013 9:39 pm

- Location: PA

Re: Alternate Baffle Seal

Here we got our rear and side baffles installed as one piece.

This corner is puckering up. The seal in the previous picture is one continuous strip. I snipped the corner a bit but it still doesn't behave. Any suggestions?

This corner is puckering up. The seal in the previous picture is one continuous strip. I snipped the corner a bit but it still doesn't behave. Any suggestions?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

15 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: Google [Bot] and 1 guest