random user submitted photo

General Info wanted about temps

29 posts

• Page 3 of 3 • 1, 2, 3

Re: General Info wanted about temps

Honestly, I've never found sealing the heck out of the baffles to change anything. I think sealing every little crack and opening is over rated in the Sonex cowl. That said, I did put a piece of heat resistant tape over the hole in the engine case that you point to.

Your engine is going to run hot at the beginning. That's the nature of new engines. Just try the suggestions people have presented here, keeping the CHT temps below 400F, and run at 3,000 rpm or more as much as possible within temperature limits. Don't worry too much about EGTs. It's the CHTs that really mean something. EGTs are just an indicator rather than an absolute.

Your engine is going to run hot at the beginning. That's the nature of new engines. Just try the suggestions people have presented here, keeping the CHT temps below 400F, and run at 3,000 rpm or more as much as possible within temperature limits. Don't worry too much about EGTs. It's the CHTs that really mean something. EGTs are just an indicator rather than an absolute.

Mike Smith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

- mike.smith

- Posts: 1430

- Joined: Tue Jan 29, 2013 8:45 pm

Re: General Info wanted about temps

Darick,

It looks like you paid a lot of attention to detail on the baffles. There's a couple places that could be improved like the forward left corner and the gap at the aft left corner. I agree with Mike, though, and don't think it needs to be perfect. I might be misinterpreting the picture, but the aft left rubber extrusion seems to not be "P" shaped. If you had to modify it, are you sure it isn't getting blown backwards and allowing air to leak past?

In the picture of the cowl exit, it looks like the right exhaust doesn't stick out below the bottom of the fuselage. I don't think this would only effect one side of the engine, though, and I might just be misinterpreting the picture.

From the extra information you provided, I now feel it is less likely to be a secondary ignition timing issue, since #1 and #3 use the same ignition module and coil.

Some more ideas:

Anything different about the way the thermocouples are wired? Something like one had to be spliced to copper wire inside the engine compartment and the other was able to run through the firewall? This can cause errors since each splice of dissimilar metals acts like an extra thermocouple.

Are there any problems with flashing closing gaps between the cylinder head fins of cylinder 1?

Have you removed the rocker cover on the left side to make sure there's plenty of oil getting to the left side? This could cause the oil temperature to be low while the cylinder is hot. Is there any discoloration inside yet to visually tell that the left side really is hotter than the right?

It looks like you paid a lot of attention to detail on the baffles. There's a couple places that could be improved like the forward left corner and the gap at the aft left corner. I agree with Mike, though, and don't think it needs to be perfect. I might be misinterpreting the picture, but the aft left rubber extrusion seems to not be "P" shaped. If you had to modify it, are you sure it isn't getting blown backwards and allowing air to leak past?

In the picture of the cowl exit, it looks like the right exhaust doesn't stick out below the bottom of the fuselage. I don't think this would only effect one side of the engine, though, and I might just be misinterpreting the picture.

From the extra information you provided, I now feel it is less likely to be a secondary ignition timing issue, since #1 and #3 use the same ignition module and coil.

Some more ideas:

Anything different about the way the thermocouples are wired? Something like one had to be spliced to copper wire inside the engine compartment and the other was able to run through the firewall? This can cause errors since each splice of dissimilar metals acts like an extra thermocouple.

Are there any problems with flashing closing gaps between the cylinder head fins of cylinder 1?

Have you removed the rocker cover on the left side to make sure there's plenty of oil getting to the left side? This could cause the oil temperature to be low while the cylinder is hot. Is there any discoloration inside yet to visually tell that the left side really is hotter than the right?

Last edited by gammaxy on Mon Dec 04, 2017 10:42 am, edited 1 time in total.

- gammaxy

- Posts: 601

- Joined: Wed Sep 04, 2013 9:31 am

Re: General Info wanted about temps

Chris...

P shaped baffle...yes I slit it so the cowl would go down easier. No I'm not sure it's not blowing back. I will bend it forward instead of back when putting the cowl on...just how to do that?...I don't know yet.

Yes, left exhaust is below cowl in that pic, but that was before I trimmed it to match the right. They are actually cut even with the fuselage bottom. Did I mistakenly cut them too short?

As I remember, the t-couples are spliced the same way, same place inside the cockpit.

No obvious problems with flashing gaps.

No, I haven't removed the rocker cover but will check that.

Thanks for your input.

P shaped baffle...yes I slit it so the cowl would go down easier. No I'm not sure it's not blowing back. I will bend it forward instead of back when putting the cowl on...just how to do that?...I don't know yet.

Yes, left exhaust is below cowl in that pic, but that was before I trimmed it to match the right. They are actually cut even with the fuselage bottom. Did I mistakenly cut them too short?

As I remember, the t-couples are spliced the same way, same place inside the cockpit.

No obvious problems with flashing gaps.

No, I haven't removed the rocker cover but will check that.

Thanks for your input.

Darick Gundy

Sonex #1646

N417DG

Taildragger, Aerovee, center stick, Prince P-Tip Prop

MGL E1, F2, V6 radio, Sandia Xponder, Reserve lift indicator (AOA), iFly 520

First flight! 10/21/2017

Sonex #1646

N417DG

Taildragger, Aerovee, center stick, Prince P-Tip Prop

MGL E1, F2, V6 radio, Sandia Xponder, Reserve lift indicator (AOA), iFly 520

First flight! 10/21/2017

-

Darick - Posts: 496

- Joined: Mon Aug 05, 2013 9:39 pm

- Location: PA

Re: General Info wanted about temps

I think Chris has a point about the baffle seal on that back left top corner.....maybe it IS blowing back and losing it's seal? Personally I don't like the baffle seal material that Sonex uses and plan to go with the traditional seal material that I used on my RV/Lycoming installation. With that type of seal, as the cowl "blows up" slightly at high speed, it doesn't lose it's seal and will hold the air pressure.

Something to think about.

Gordon........Onex......Hummel 2400

Something to think about.

Gordon........Onex......Hummel 2400

- Gordon

- Posts: 178

- Joined: Thu Sep 07, 2017 9:20 pm

Re: General Info wanted about temps

Darick,

Max oil temp of 145 deg F confirms that you're over-cooling your oil. This means you're bringing in excessive air into the oil cooler inlet, and that air in turn is pressurizing the lower cowl and reducing the pressure differential from top to bottom. You should tape over half of the oil cooler cowl inlet using some blue painter's tape for your next couple flights and see how that affects the oil temp. I suspect that even then you will have low oil temps (maybe 180 or so).

The exhaust exits look like a significant portion of the cross sectional area is being obstructed by the lower firewall structure and the engine mount cross tube. You can try and measure the area of the exit as it sits on the plane to get a better feel for how much, but the simple thing would be to just cut the opening bigger. I suggest you drill out the rivets holding the deflector lips in place, cut the fiberglass cowling opening two inches forward (towards the spinner), and re-install the deflector lips. This will give you better draw of cooling air thru the cowl and help your CHTs.

The left-right difference in CHT's suggest that cooling air is able to pass thru the right (passenger) side of the baffles easier than the left (pilot side). Look at the undersides of the cylinders and see how big the airflow gaps are (especially at the back of the baffles between the rear cylinder and back baffle fence). If the gaps are larger, more air will flow on that side, and cooling will be uneven, like you're reporting. If the gaps appear the same, it could be due to the cowling inlets, and/or the corkscrewing air entering the cowling and/or flowing over the bottom of the cowling. Smoothing out your cowl inlet lips on the inside will help (at least 10-20 deg F), and you might need to make the right side exit slightly larger than the left to do the final tweaking to airflow thru the baffles.

I Know this situation is frustrating, but these adjustments and some additional hours on the engine will get you to where you need to be. Modify your cowl exits, tape over some of your oil cooler inlet, and go fly for 2 or 3 2-hr flights. It's OK if the engine runs at the top of the allowable range for a short time while you takeoff and climb to 1500 ft, but once you are there, set it for 3000 rpm and just let it cruise for at least an hour at a time. During this time you can experiment with turning off your secondary ignition and observing the trend. That will answer your timing question. This is the quickest way to get your engine broken in.

PM me if you want to talk in more detail.

Jeff

Max oil temp of 145 deg F confirms that you're over-cooling your oil. This means you're bringing in excessive air into the oil cooler inlet, and that air in turn is pressurizing the lower cowl and reducing the pressure differential from top to bottom. You should tape over half of the oil cooler cowl inlet using some blue painter's tape for your next couple flights and see how that affects the oil temp. I suspect that even then you will have low oil temps (maybe 180 or so).

The exhaust exits look like a significant portion of the cross sectional area is being obstructed by the lower firewall structure and the engine mount cross tube. You can try and measure the area of the exit as it sits on the plane to get a better feel for how much, but the simple thing would be to just cut the opening bigger. I suggest you drill out the rivets holding the deflector lips in place, cut the fiberglass cowling opening two inches forward (towards the spinner), and re-install the deflector lips. This will give you better draw of cooling air thru the cowl and help your CHTs.

The left-right difference in CHT's suggest that cooling air is able to pass thru the right (passenger) side of the baffles easier than the left (pilot side). Look at the undersides of the cylinders and see how big the airflow gaps are (especially at the back of the baffles between the rear cylinder and back baffle fence). If the gaps are larger, more air will flow on that side, and cooling will be uneven, like you're reporting. If the gaps appear the same, it could be due to the cowling inlets, and/or the corkscrewing air entering the cowling and/or flowing over the bottom of the cowling. Smoothing out your cowl inlet lips on the inside will help (at least 10-20 deg F), and you might need to make the right side exit slightly larger than the left to do the final tweaking to airflow thru the baffles.

I Know this situation is frustrating, but these adjustments and some additional hours on the engine will get you to where you need to be. Modify your cowl exits, tape over some of your oil cooler inlet, and go fly for 2 or 3 2-hr flights. It's OK if the engine runs at the top of the allowable range for a short time while you takeoff and climb to 1500 ft, but once you are there, set it for 3000 rpm and just let it cruise for at least an hour at a time. During this time you can experiment with turning off your secondary ignition and observing the trend. That will answer your timing question. This is the quickest way to get your engine broken in.

PM me if you want to talk in more detail.

Jeff

- sonex1374

- Posts: 605

- Joined: Thu Mar 27, 2014 1:02 am

Re: General Info wanted about temps

I found a potential restriction today. The baffle aft of the #1 cylinder has a small bent shape at the bottom (using your imagination it sort of resembles a teardrop) which goes between the super tin and the cylinder. It fit really tight and extended down in between about 1-1/2".

I pushed the baffle aft so that the teardrop was withdrawn which is what the picture shows. It is outlined in red. The arrow points to the space between the cylinder and the super tin which is where the teardrop was located. Instead of directing the air down around the cylinder it may have just obstructed the passage way.

It is now in its new position, as in the picture, with red RTV added after this pic was taken. I will be blocking off at least half of the oil intake cooling hole, enlarging the cowl exit as suggested by Jeff and go fly as soon as the weather clears up and is above 40 degrees. But looking at the forecast, that could now be March 2018.

I realize you should only be doing one change at a time, but these changes should have been part of the original construction and will now be closer to the intended design...my error as a newbie builder.

If this works I'll really be happy, since the #3 cylinder which is usually the hottest, was never above 390.

To all new builders...watching the Sonex videos and podcasts are a great way to stay pumped...just watched Mike Smith aerobatic YouTube videos, the Alaska adventures and listened to the latest Subsonex podcasts!

I pushed the baffle aft so that the teardrop was withdrawn which is what the picture shows. It is outlined in red. The arrow points to the space between the cylinder and the super tin which is where the teardrop was located. Instead of directing the air down around the cylinder it may have just obstructed the passage way.

It is now in its new position, as in the picture, with red RTV added after this pic was taken. I will be blocking off at least half of the oil intake cooling hole, enlarging the cowl exit as suggested by Jeff and go fly as soon as the weather clears up and is above 40 degrees. But looking at the forecast, that could now be March 2018.

I realize you should only be doing one change at a time, but these changes should have been part of the original construction and will now be closer to the intended design...my error as a newbie builder.

If this works I'll really be happy, since the #3 cylinder which is usually the hottest, was never above 390.

To all new builders...watching the Sonex videos and podcasts are a great way to stay pumped...just watched Mike Smith aerobatic YouTube videos, the Alaska adventures and listened to the latest Subsonex podcasts!

Darick Gundy

Sonex #1646

N417DG

Taildragger, Aerovee, center stick, Prince P-Tip Prop

MGL E1, F2, V6 radio, Sandia Xponder, Reserve lift indicator (AOA), iFly 520

First flight! 10/21/2017

Sonex #1646

N417DG

Taildragger, Aerovee, center stick, Prince P-Tip Prop

MGL E1, F2, V6 radio, Sandia Xponder, Reserve lift indicator (AOA), iFly 520

First flight! 10/21/2017

-

Darick - Posts: 496

- Joined: Mon Aug 05, 2013 9:39 pm

- Location: PA

Re: General Info wanted about temps

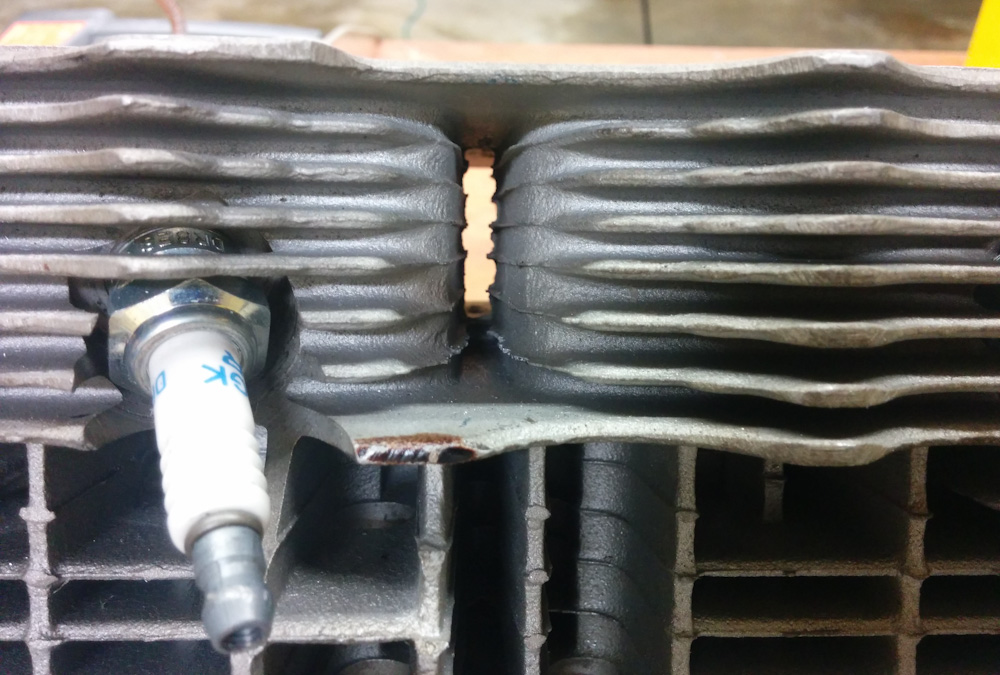

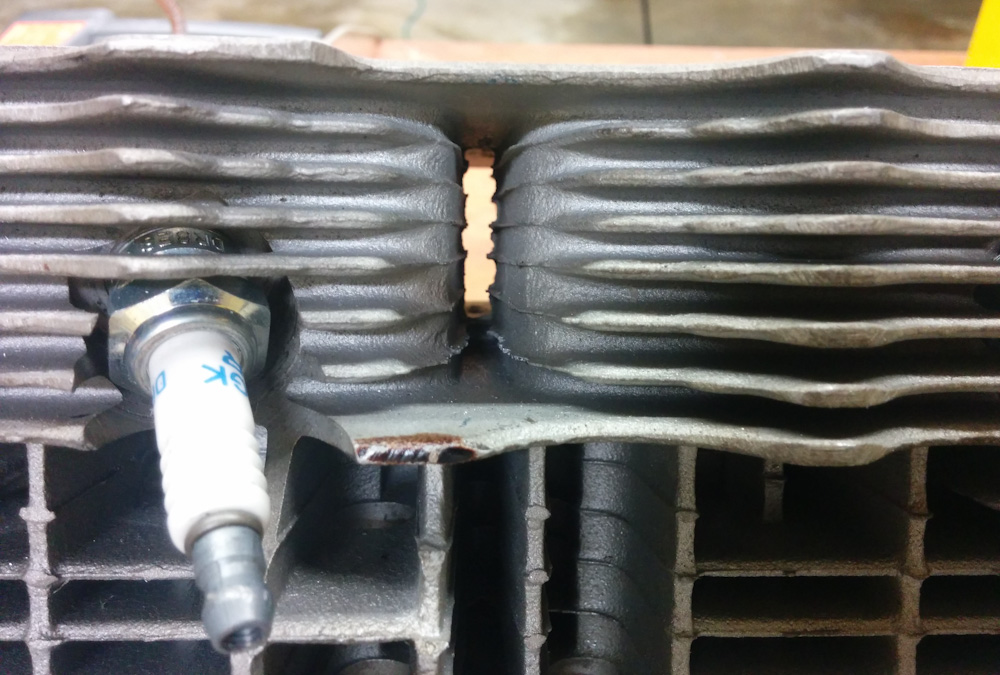

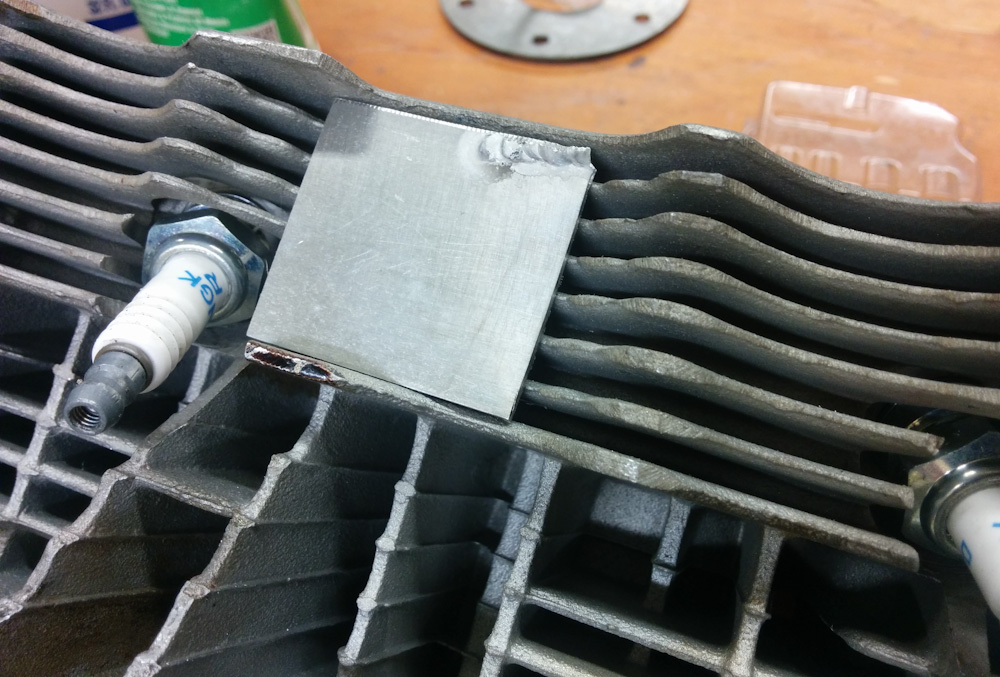

I just came across an interesting post by Bob Hoover about head cooling. I can't find it now (edit: here), but he states that on stock VW heads there is supposed to be a (frequently absent) blocking plate on the bottom, between the cylinders. In this area:

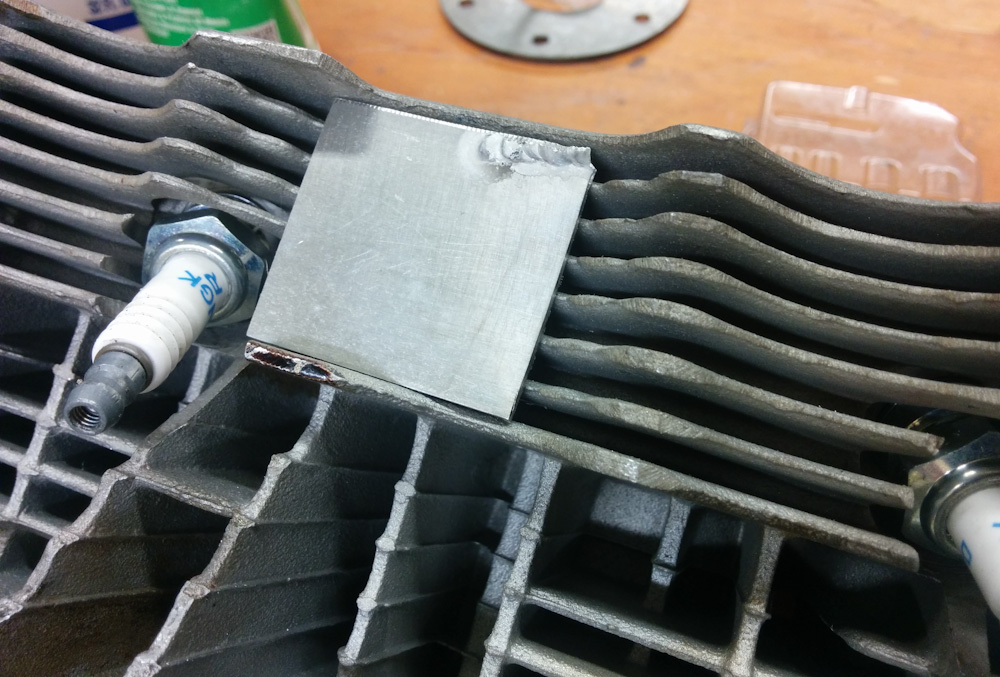

It prevents the air from flowing straight down and out through this rather large hole and instead forces it through the cooling fins on the bottom of the heads. The fins on the Aerovee heads also have an indentation in this area, indicating that something's supposed to be located here. Something like this:

I've never come across anything about this in the Aerovee instructions or on this forum. Has anyone heard about it and added such a plate? It makes sense that you don't want air to flow freely through this rather large hole but instead force it through the fins. I'm going to make some squares and RTV them in place on our heads, it certainly can't hurt, but I wonder if anyone's heard of or tried this before?

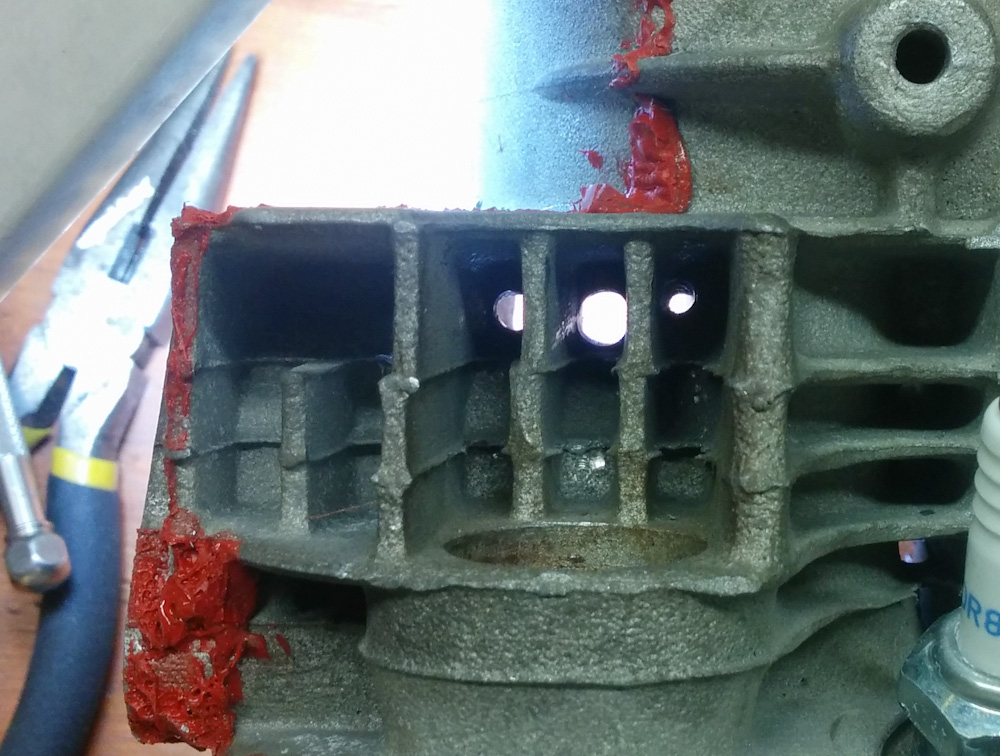

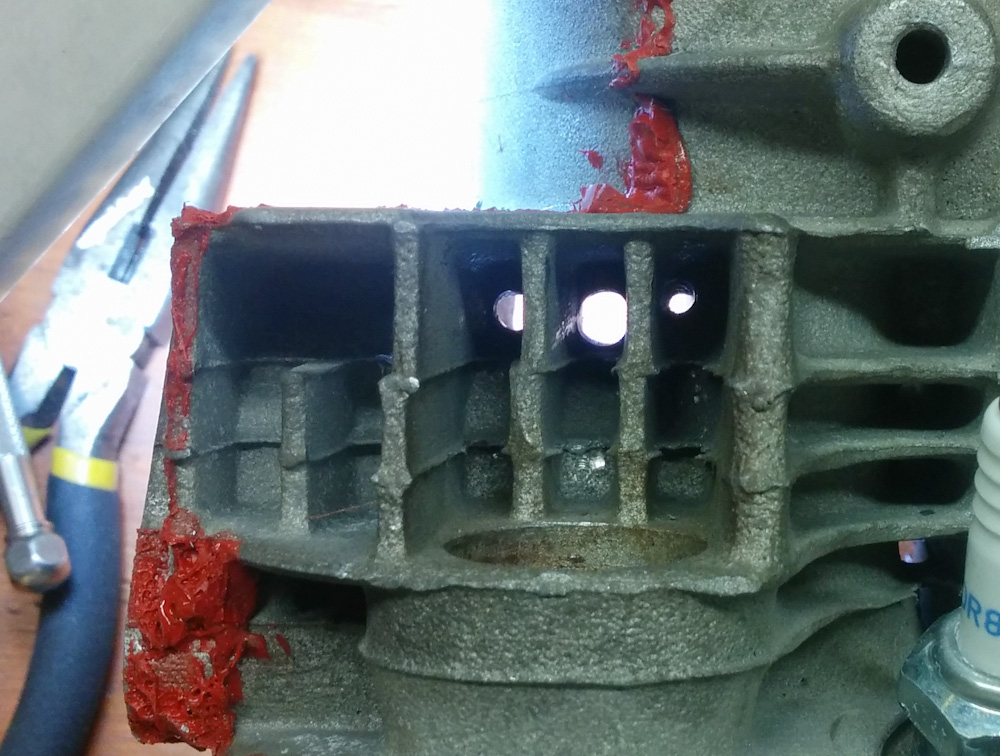

I also went all out on drilling out the air passages around the exhaust port:

I'm not sure the hole on the right, next to the exhaust valve guide, really should be there. I had to drill through maybe 5mm of material to get through there. But it seems weird to not have any airflow there since you just get a bunch of stagnant air in that pocket otherwise.

I also got a bit innovative and drilled an air passage hole for the fin cavity on the left in the picture above, next to the exhaust flange. You can't drill through the head here, the exhaust studs are in the way, but you can drill diagonally. Like this:

This hole will still exit below the baffles, so it should work normally, and having a through-hole in all the cavities here should improve cooling a lot over just having stagnant air sit in them. And there's a lot of clearance to the exhaust port itself, I'm not at all worried about the material being too thin.

What do you guys think? Crazy?

(The images are a bit cut off when viewed in-line, it seems. If you right-click on them and "open in new tab", you'll see the whole thing. Nothing important is missing, though.

It prevents the air from flowing straight down and out through this rather large hole and instead forces it through the cooling fins on the bottom of the heads. The fins on the Aerovee heads also have an indentation in this area, indicating that something's supposed to be located here. Something like this:

I've never come across anything about this in the Aerovee instructions or on this forum. Has anyone heard about it and added such a plate? It makes sense that you don't want air to flow freely through this rather large hole but instead force it through the fins. I'm going to make some squares and RTV them in place on our heads, it certainly can't hurt, but I wonder if anyone's heard of or tried this before?

I also went all out on drilling out the air passages around the exhaust port:

I'm not sure the hole on the right, next to the exhaust valve guide, really should be there. I had to drill through maybe 5mm of material to get through there. But it seems weird to not have any airflow there since you just get a bunch of stagnant air in that pocket otherwise.

I also got a bit innovative and drilled an air passage hole for the fin cavity on the left in the picture above, next to the exhaust flange. You can't drill through the head here, the exhaust studs are in the way, but you can drill diagonally. Like this:

This hole will still exit below the baffles, so it should work normally, and having a through-hole in all the cavities here should improve cooling a lot over just having stagnant air sit in them. And there's a lot of clearance to the exhaust port itself, I'm not at all worried about the material being too thin.

What do you guys think? Crazy?

(The images are a bit cut off when viewed in-line, it seems. If you right-click on them and "open in new tab", you'll see the whole thing. Nothing important is missing, though.

- lutorm

- Posts: 259

- Joined: Mon May 15, 2017 1:35 pm

- Location: The Island of Hawai

Re: General Info wanted about temps

Patrik,

I drilled the holes out between the cooling fins as you describe. I did not see any notable difference in CHTs as a result.

On the Aerovee we use the “Super Tin” underneath the cylinder and heads. Perhaps that is why the plate between the cylinders is not typically found on the heads now a days. Does your engine have the Super Tins?

Jake

I drilled the holes out between the cooling fins as you describe. I did not see any notable difference in CHTs as a result.

On the Aerovee we use the “Super Tin” underneath the cylinder and heads. Perhaps that is why the plate between the cylinders is not typically found on the heads now a days. Does your engine have the Super Tins?

Jake

Sonex Tri Gear, Rotax 912 ULS, Sensenich 3 Blade Ground Adjustable Propeller

MGL Velocity EMS, Garmin GTR 200 Comm, GTX 335 ADS B Out Transponder

ILevil AW AHRS & ADS-B In, UAvionix AV20S

200+ hours previously with Aerovee engine

Sarasota, Florida

MGL Velocity EMS, Garmin GTR 200 Comm, GTX 335 ADS B Out Transponder

ILevil AW AHRS & ADS-B In, UAvionix AV20S

200+ hours previously with Aerovee engine

Sarasota, Florida

-

SonexN76ET - Posts: 494

- Joined: Tue Aug 27, 2013 2:39 pm

- Location: Atlanta

Re: General Info wanted about temps

SonexN76ET wrote:Patrik,

I drilled the holes out between the cooling fins as you describe. I did not see any notable difference in CHTs as a result.

On the Aerovee we use the “Super Tin” underneath the cylinder and heads. Perhaps that is why the plate between the cylinders is not typically found on the heads now a days. Does your engine have the Super Tins?

Jake

It has the SuperTins, but apart from two sections on the sides of the heads, they only wrap around the cylinders. This area is not covered by them.

- lutorm

- Posts: 259

- Joined: Mon May 15, 2017 1:35 pm

- Location: The Island of Hawai

29 posts

• Page 3 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 7 guests