random user submitted photo

Cotton AeroVee 0795

Re: Cotton AeroVee 0795

I am glad the World Series is over. I am not a sports fan but Adam has become one. Now I have my co-builder back. Here is Adam experiencing the ring compressor for the first time.

He got pretty good at getting the piston into the jug. The third cyclinder was killing us though. Every time we tried to push it back out to expose the wristpin we went too far and the oil ring popped out. Adam had 6 tries and I took one. Then we decided this was a sign it was quitting time.

He got pretty good at getting the piston into the jug. The third cyclinder was killing us though. Every time we tried to push it back out to expose the wristpin we went too far and the oil ring popped out. Adam had 6 tries and I took one. Then we decided this was a sign it was quitting time.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

Here is the solution for putting the piston in the right amount. We put about 4.2" of shims in the cylinder. In the picture the cylinder needs to be flipped over before we put the piston in.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

Remember I said we flipped the cylinder over before putting the piston in? I guess not!

First cylinder going on:

Permatex time. The bigger the blob, the better the job- right? Only kidding, I've taught him to use it sparingly.

Going:

And, one side done. Then he was out for a lesson in the J3.

First cylinder going on:

Permatex time. The bigger the blob, the better the job- right? Only kidding, I've taught him to use it sparingly.

Going:

And, one side done. Then he was out for a lesson in the J3.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

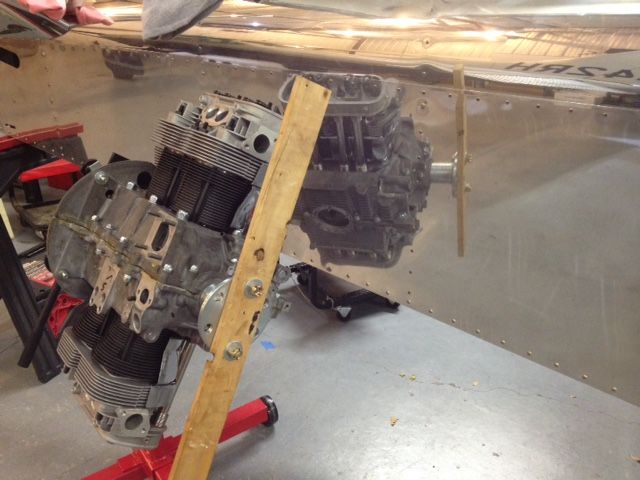

Head in place. Thanks to all who discussed pushrod tubes via the other thread and email. Mine were good.

Adam torquing down head bolts:

Two heads on and torqued.

After we got back Adam went and found his Visible L4 model he built at age 11 or 12. He wants to get it working. It used to sort of work, but his skills were less back then and I didn't want to take over. Smart move.

Adam torquing down head bolts:

Two heads on and torqued.

After we got back Adam went and found his Visible L4 model he built at age 11 or 12. He wants to get it working. It used to sort of work, but his skills were less back then and I didn't want to take over. Smart move.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

You guys almost look ready to install on the airframe and have the first start!

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton AeroVee 0795

Should I run it after it is built or wait until close to taxi & flight?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

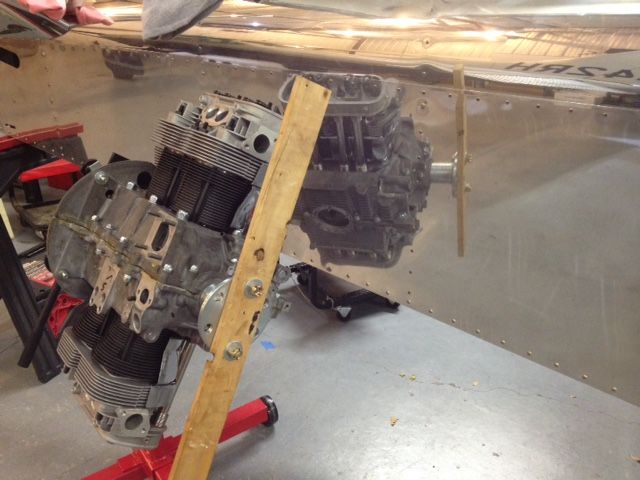

Got the studs trimmed:

This job sucks. Would be totally worth it to dry assemble the engine after the deck height check and trim the pushrods out of the engine.

I discovered the Aerovee uses the same plugs as my Saturn.

This job sucks. Would be totally worth it to dry assemble the engine after the deck height check and trim the pushrods out of the engine.

I discovered the Aerovee uses the same plugs as my Saturn.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

Bryan Cotton wrote:Should I run it after it is built or wait until close to taxi & flight?

Bryan - keep your engine pickled until your ready to do extensive ground runs and taxing, etc. I only pre-oiled mine and then the engine sat for over a year before first start. I'm just trying to encourage you and your son to keep up the good work and get closer to finishing!

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton AeroVee 0795

To trim the pushrods, I first did one by hand and considered it my "reference" pushrod. Next, I got a piece of 2X4 and drilled a couple 3/8" holes in it. The pushrods were a snug fit in the holes. On the left you can see I made a reference gauge out of scrap, so the new pushrod will always stick out of the 2X4 the same amount. This dimension can be anything, it just needs to be repeatable. Then I stuck my reference pushrod in, and squared up the ends with the ball.

Now over to the drill press. I adjusted the height of the table until the cutoff wheel just scraped on the reference pushrod.

And time to cut. The dremel wheel was not holding up so I had to find the big boy wheel.

I don't have a lathe.

And then a major setback- one of the lifters slipped out when we joined the case. We have to split it.

Crap.

Now over to the drill press. I adjusted the height of the table until the cutoff wheel just scraped on the reference pushrod.

And time to cut. The dremel wheel was not holding up so I had to find the big boy wheel.

I don't have a lathe.

And then a major setback- one of the lifters slipped out when we joined the case. We have to split it.

Crap.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton AeroVee 0795

I used a pipe cutter to cut the pushrods.

Sorry about the lifter slipping out. I'm surprised you didn't hear it moving around when you were flipping the engine back and forth. The assembly video shows how to hold the lifters in position using clothespins while assembling the case.

Sorry about the lifter slipping out. I'm surprised you didn't hear it moving around when you were flipping the engine back and forth. The assembly video shows how to hold the lifters in position using clothespins while assembling the case.

- gammaxy

- Posts: 600

- Joined: Wed Sep 04, 2013 9:31 am

Who is online

Users browsing this forum: No registered users and 12 guests