random user submitted photo

Waiex #0056 - N569KM First Flight 4/2/2012

44 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Hi Kip,

I now have three test flights completed but have been at FSI in Wilmington for recurrent all week so not much for this week. Thus far all seems to be pretty good...I'm seeing CHT's around 380-390 on climb out, and they drop to 350-360 in cruise when the EGT's are around 1150-1200. At 3000' and 3000 rpm, IAS is around 125 and the MGL calculates around 128 mph true. On my last landing I got a fairly severe brake chatter/shimmy which bent my gear leg fairing a little, so my plane is currently up on a jack to get this annoying brake issue solved before I fly again. I also keep opening the gap between my flywheel ignition magnet and upper primary coil as they were rubbing. The specs call for 0.10" gap but I'm up to 0.16" and still getting just a little rubbing so I need to go a little bigger.

The good news is the airframe itself has been great so far...I have a barely noticeable heavy right wing but it's so close I'll probably ignore it for now. I've also gone through and have written a building and flying story for the Sonex website about my adventures, so hopefully that gets posted soon.

How about you Kip...you flying your plane much?

I now have three test flights completed but have been at FSI in Wilmington for recurrent all week so not much for this week. Thus far all seems to be pretty good...I'm seeing CHT's around 380-390 on climb out, and they drop to 350-360 in cruise when the EGT's are around 1150-1200. At 3000' and 3000 rpm, IAS is around 125 and the MGL calculates around 128 mph true. On my last landing I got a fairly severe brake chatter/shimmy which bent my gear leg fairing a little, so my plane is currently up on a jack to get this annoying brake issue solved before I fly again. I also keep opening the gap between my flywheel ignition magnet and upper primary coil as they were rubbing. The specs call for 0.10" gap but I'm up to 0.16" and still getting just a little rubbing so I need to go a little bigger.

The good news is the airframe itself has been great so far...I have a barely noticeable heavy right wing but it's so close I'll probably ignore it for now. I've also gone through and have written a building and flying story for the Sonex website about my adventures, so hopefully that gets posted soon.

How about you Kip...you flying your plane much?

Mike Farley

Waiex #0056 - N569KM (sold)

Onex #245

Waiex #0056 - N569KM (sold)

Onex #245

- MichaelFarley56

- Posts: 1485

- Joined: Thu Jun 02, 2011 11:38 pm

- Location: Columbus, Ohio

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Hehe, Mike. I was a Wilmington FSI last month!

I'm getting out and around regularly in 1YX, once a week minimum. Looking forward to many fly-ins this year, my NE trip, and Oshkosh of course...!

Keep us posted on your interesting test flights...

I'm getting out and around regularly in 1YX, once a week minimum. Looking forward to many fly-ins this year, my NE trip, and Oshkosh of course...!

Keep us posted on your interesting test flights...

Kip

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

- N111YX

- Posts: 711

- Joined: Fri Jun 03, 2011 9:43 am

- Location: Atlanta, GA USA

Re: Waiex #0056 - N569KM First Flight 4/2/2012

I enjoyed your story at sonexaircraft.com, Mike. I can, like all of us builders, relate to about everything that you described.

Are the Phase I hours ticking off...?

Are the Phase I hours ticking off...?

Kip

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

- N111YX

- Posts: 711

- Joined: Fri Jun 03, 2011 9:43 am

- Location: Atlanta, GA USA

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Thanks Kip...I enjoyed writing it. Although I think I still like watching your videos more!

Phase 1 is going slower than I was hoping. I'm trying to stick with a 5 knot crosswind limit and the winds in central Ohio have been pretty strong lately. I recently took your advice and added a 20 degree notch to my flap detents, as well as installed your tailwheel bracket and a Vans tailwheel.

Hopefully I will be able to get some hours on the plane soon. How's the Pitts project coming along?

Phase 1 is going slower than I was hoping. I'm trying to stick with a 5 knot crosswind limit and the winds in central Ohio have been pretty strong lately. I recently took your advice and added a 20 degree notch to my flap detents, as well as installed your tailwheel bracket and a Vans tailwheel.

Hopefully I will be able to get some hours on the plane soon. How's the Pitts project coming along?

Mike Farley

Waiex #0056 - N569KM (sold)

Onex #245

Waiex #0056 - N569KM (sold)

Onex #245

- MichaelFarley56

- Posts: 1485

- Joined: Thu Jun 02, 2011 11:38 pm

- Location: Columbus, Ohio

Re: Waiex #0056 - N569KM First Flight 4/2/2012

This is it, Mike. All 36 ribs complete. I still have the aileron ribs yet to do before I can a really complain about not having the rest of the wing kit (spars, ect.). That stuff was due in December... :x

- Attachments

-

- 36Ribs2.JPG (71.78 KiB) Viewed 14106 times

-

- 36Ribs1.JPG (65.73 KiB) Viewed 14106 times

Kip

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

- N111YX

- Posts: 711

- Joined: Fri Jun 03, 2011 9:43 am

- Location: Atlanta, GA USA

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Man Kip that's awesome!! Those look great! I have a stupid question for you...are there ailerons on both wings or bottom only? Hopefully your spars and hardware will be here soon. Has the fuselage been ordered yet? Thanks for sharing and keep with the updates.

Mike Farley

Waiex #0056 - N569KM (sold)

Onex #245

Waiex #0056 - N569KM (sold)

Onex #245

- MichaelFarley56

- Posts: 1485

- Joined: Thu Jun 02, 2011 11:38 pm

- Location: Columbus, Ohio

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Mike, I'm building the S-1C model which is the first and most primitive version. It has ailerons only on the bottom wings.

There are three options for the fuselage...order a new one for $14K, find a used one for significantly less or, learn to weld. I'm not sure which path to take yet...:)

There are three options for the fuselage...order a new one for $14K, find a used one for significantly less or, learn to weld. I'm not sure which path to take yet...:)

Kip

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

- N111YX

- Posts: 711

- Joined: Fri Jun 03, 2011 9:43 am

- Location: Atlanta, GA USA

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Welding scares me so I'd probably be looking for a good used one, then as a last resort a new one. Can you find good used ones around?

Mike Farley

Waiex #0056 - N569KM (sold)

Onex #245

Waiex #0056 - N569KM (sold)

Onex #245

- MichaelFarley56

- Posts: 1485

- Joined: Thu Jun 02, 2011 11:38 pm

- Location: Columbus, Ohio

Re: Waiex #0056 - N569KM First Flight 4/2/2012

They are out there. Plenty of time to find one... :lol:

MichaelFarley56 wrote:Welding scares me so I'd probably be looking for a good used one, then as a last resort a new one. Can you find good used ones around?

Kip

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1175 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

- N111YX

- Posts: 711

- Joined: Fri Jun 03, 2011 9:43 am

- Location: Atlanta, GA USA

Re: Waiex #0056 - N569KM First Flight 4/2/2012

Hello All,

I wanted to post a quick update on Waiex #0056 and the progress I've been making. Thus far I'm still working on finishing Phase 1 test hours as the plane has around 25 hours on it. The first 10 took a while as each flight ended up with a list of tweaks and adjustments before the next flight took place. Once I got over 10-15 hours, I've been able to get some more flight time and have been stretching the legs longer and longer.

First off, if you're still building and are wondering if it's worth it, trust me...these planes are a blast to fly!! My Waiex still has my attention on landing ( I'm still a tailwheel newbie) but all aspects of flight in these planes are a complete joy. My AeroVee powered plane gets off the ground in around 800' - 1000' easily and I've been lifting off around 60 mph. Initial climb rates around 100 mph are giving me around 500 fpm, but outside air temperature can have an impact. Now that it's hot and humid in Ohio I'm doing a lot of cruise climbing to keep my CHT's at or below 390. Once I level off I've been seeing CHTs around 350-360 @ 3100 rpm, 1175 on the EGTs and TAS of right around 135 mph. This is at around 6ish GPH.

As for my tweaks, here's my list of adjustments I've made on my plane:

- the primary ignition coil gap between the coils and the flywheel is supposed to be 0.010". I was getting rubbing and it finally stopped once I opened the gap to 0.018". For those with AeroVees, take that metal gap strip and run around 3-4 strips of painters tape on it to open that gap up a little. Trust me, that tiny little gap closes once things warm up.

- I initially started with my COM antenna on the glareshield as per the plans. This led to bad reception as I could only hear airplanes certain directions from me and only up to around 10-15 miles. I moved my antenna to the top of the turtleneck and it was a huge upgrade. I can now talk with other planes up to 100 miles away.

- I'm still working on my brakes but make sure there's no rubbing between the brake shoes and drums. I was getting a lot of shaking on landing that has gotten better but I had to make a lot of small tweaks. Also, when you put your wheels and tires together, try to balance them. It helps.

-my biggest advice thus far... If you make a fuel line from the firewall to the carb, make sure you really clean out the inside of the hose well. I was flying along with over 20 hours on the airplane when I got a glob of fuel line dislodge and plug up my needle valve which killed my engine. Thankfully I was close enough to my airport that I could dead stick back for a landing. This wasn't the airplanes fault...I obviously didn't check that line well enough. Use high pressure air or something to really get that cleaned up well on the inside!

-I'm going to pass along the wonderful advice Kip gave me...take your flap detent bracket out and cut a 20 degree flap notch in it. I started landings at 10 degrees and still do if it's windy, but my normal position is that 20 degree setting. Normally, I'll pull 10 degrees down at 100 on downwind and then 20 degrees once I slow to 90 on base. Final is around 80 until short final which works well. 30 degrees is a huge amount of flap and it's tough to pull the handle back that far.

Other than that, everything has been going very well. My oil pressure has been averaging around 70 psi in cruise which is leading to oil on the belly after every flight. I'm going to order an air/oil separator and see if that helps, but my only other task at this point is to keep polishing and get my wing leading edges painted. I'm really hoping to make it to Oshkosh this year so hopefully the weather stays good and I can finish Phase 1 soon.

Here's a few new pics:

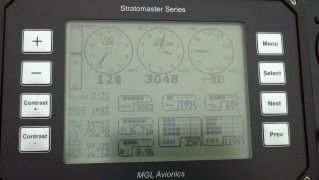

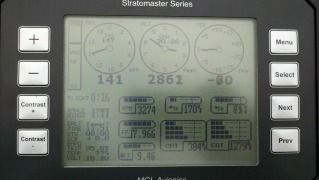

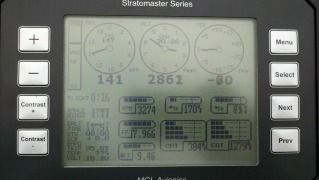

Normal cruise:

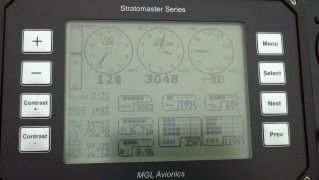

Breaking in engine:

Still polishing wings:

So far...

I wanted to post a quick update on Waiex #0056 and the progress I've been making. Thus far I'm still working on finishing Phase 1 test hours as the plane has around 25 hours on it. The first 10 took a while as each flight ended up with a list of tweaks and adjustments before the next flight took place. Once I got over 10-15 hours, I've been able to get some more flight time and have been stretching the legs longer and longer.

First off, if you're still building and are wondering if it's worth it, trust me...these planes are a blast to fly!! My Waiex still has my attention on landing ( I'm still a tailwheel newbie) but all aspects of flight in these planes are a complete joy. My AeroVee powered plane gets off the ground in around 800' - 1000' easily and I've been lifting off around 60 mph. Initial climb rates around 100 mph are giving me around 500 fpm, but outside air temperature can have an impact. Now that it's hot and humid in Ohio I'm doing a lot of cruise climbing to keep my CHT's at or below 390. Once I level off I've been seeing CHTs around 350-360 @ 3100 rpm, 1175 on the EGTs and TAS of right around 135 mph. This is at around 6ish GPH.

As for my tweaks, here's my list of adjustments I've made on my plane:

- the primary ignition coil gap between the coils and the flywheel is supposed to be 0.010". I was getting rubbing and it finally stopped once I opened the gap to 0.018". For those with AeroVees, take that metal gap strip and run around 3-4 strips of painters tape on it to open that gap up a little. Trust me, that tiny little gap closes once things warm up.

- I initially started with my COM antenna on the glareshield as per the plans. This led to bad reception as I could only hear airplanes certain directions from me and only up to around 10-15 miles. I moved my antenna to the top of the turtleneck and it was a huge upgrade. I can now talk with other planes up to 100 miles away.

- I'm still working on my brakes but make sure there's no rubbing between the brake shoes and drums. I was getting a lot of shaking on landing that has gotten better but I had to make a lot of small tweaks. Also, when you put your wheels and tires together, try to balance them. It helps.

-my biggest advice thus far... If you make a fuel line from the firewall to the carb, make sure you really clean out the inside of the hose well. I was flying along with over 20 hours on the airplane when I got a glob of fuel line dislodge and plug up my needle valve which killed my engine. Thankfully I was close enough to my airport that I could dead stick back for a landing. This wasn't the airplanes fault...I obviously didn't check that line well enough. Use high pressure air or something to really get that cleaned up well on the inside!

-I'm going to pass along the wonderful advice Kip gave me...take your flap detent bracket out and cut a 20 degree flap notch in it. I started landings at 10 degrees and still do if it's windy, but my normal position is that 20 degree setting. Normally, I'll pull 10 degrees down at 100 on downwind and then 20 degrees once I slow to 90 on base. Final is around 80 until short final which works well. 30 degrees is a huge amount of flap and it's tough to pull the handle back that far.

Other than that, everything has been going very well. My oil pressure has been averaging around 70 psi in cruise which is leading to oil on the belly after every flight. I'm going to order an air/oil separator and see if that helps, but my only other task at this point is to keep polishing and get my wing leading edges painted. I'm really hoping to make it to Oshkosh this year so hopefully the weather stays good and I can finish Phase 1 soon.

Here's a few new pics:

Normal cruise:

Breaking in engine:

Still polishing wings:

So far...

Mike Farley

Waiex #0056 - N569KM (sold)

Onex #245

Waiex #0056 - N569KM (sold)

Onex #245

- MichaelFarley56

- Posts: 1485

- Joined: Thu Jun 02, 2011 11:38 pm

- Location: Columbus, Ohio

44 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

Who is online

Users browsing this forum: No registered users and 6 guests