random user submitted photo

Dimpling in tight places

5 posts

• Page 1 of 1

Dimpling in tight places

On my mini rudder, the skin rivets were lined up with the bottom rivets and it looked like I would have an interference when I went to pull the rivets. I decided to use flush AN rivets on the one row of the drive horn. 3 of those rivets went through a forward rib that would need to be dimpled, but the holes were way too close to the radius to get a dimple die. I used a 100 degree pop rivet dimpler half and a #6 screw. It came out slightly over dimpled but good. Maybe using a rivet as the male die would have worked. I used a flush set against the screw head and nothing but the female dimple die on the other side.

- Attachments

-

- image.jpg (83.64 KiB) Viewed 16554 times

-

- image.jpg (63.19 KiB) Viewed 16554 times

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Dimpling in tight places

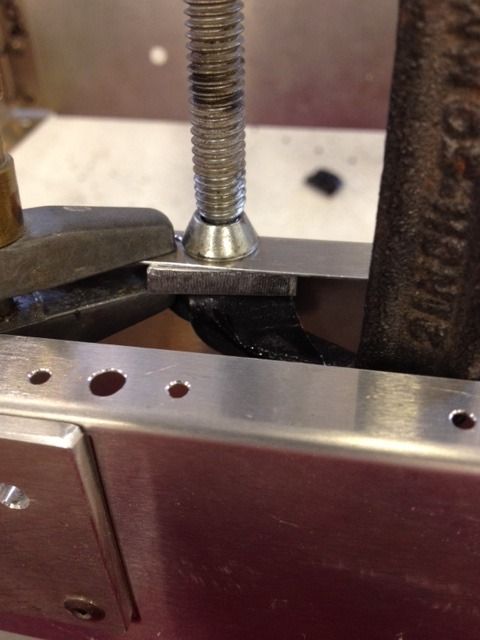

Here is an update on this technique for super tight places. I took a stainless 3/32" flush pop and removed the mandrel. I countersunk a piece of 3/16 scrap. On the C clamp I taped a couple washers to it in cas the rivet stuck out. A thicker piece of scrap would probably be better.

Then you squash it in with the C clamp.

On these dimples I recommend doing them BEFORE you rivet the parts together. Whoops!

Then you squash it in with the C clamp.

On these dimples I recommend doing them BEFORE you rivet the parts together. Whoops!

Last edited by Bryan Cotton on Mon May 11, 2015 11:34 pm, edited 1 time in total.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Dimpling in tight places

That seems kindof clever. Are you talking about countersinking the holes for the aluminum rivets on the "wings" of the nutplates? I used my deburring tool to remove just enough material from those holes so the rivets were flush.

- gammaxy

- Posts: 601

- Joined: Wed Sep 04, 2013 9:31 am

Re: Dimpling in tight places

Whoops, I posted the wrong second picture. It is fixed now. I dimpled rather than countersunk because .025 is too thin to properly countersink, not that it can't be done. Material that is at least .032" is ok to countersink for 3/32" flush rivets. I am going to put a little .032 countersunk shim between the channel and nutplate.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Dimpling in tight places

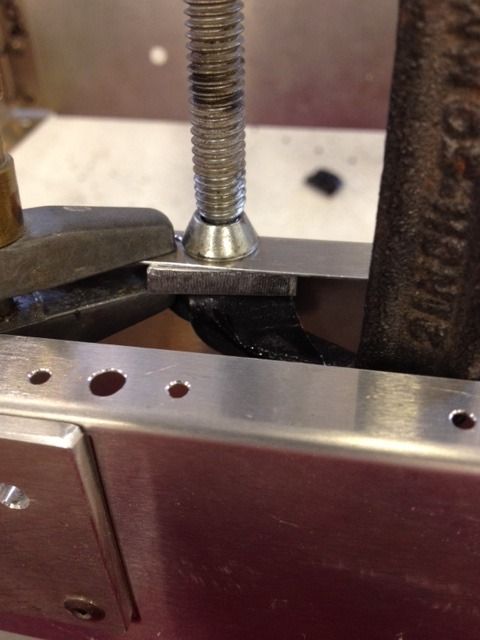

Here is another technique, as I forgot the first one and did something new. Countersink a piece of scrap for a 3/32" flush rivet. Then screw a #4 flush screw through the piece and into the countersink.

Edit: here it is in action. Not perfect as it oversizes the hole a bit but workable. Better for solid rivets than pops.

Edit: here it is in action. Not perfect as it oversizes the hole a bit but workable. Better for solid rivets than pops.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

5 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 1 guest