random user submitted photo

Sonex 1534 Photos

Re: Sonex 1534 Photos

I agree with Scott, great photos. I like the 2-33 photo too. Used to work at Schweizer and have a bunch of time in the back of the old gal.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Sonex 1534 Photos

I was able to get a couple hours testing slow flight, stalls, climbs and descents. Heroes link to a video of take off and some flying over Wm. J. Fox Airfield. It was clear, calm and 75 degrees. I moved the throttle from the center to the left side.

https://www.youtube.com/watch?v=2zAbJzb ... e=youtu.be

https://www.youtube.com/watch?v=2zAbJzb ... e=youtu.be

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Re: Sonex 1534 Photos

I noticed your hair blowing a bit, and your side vents don't have directional control from what little I know. Is that just because there's so much air being forced in that it swirls around? I'm just thinking about way in the future when it comes time to do my panel layout whether I would put vents on like so many others or be able to save the space for other avionics. I guess you'll have a better understanding how good your airflow is come summer time.

- mike20sm

- Posts: 88

- Joined: Tue Dec 02, 2014 9:32 pm

- Location: Southern California

Re: Sonex 1534 Photos

I have the van's vents on the side. I had one vent open on my side halfway. It was 75 degrees outside at 7000 ft MSL at 7am here. When I landed it was already 80 degrees at 9am. They work very well and blow air all over. I am very happy with them.

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Re: Sonex 1534 Photos

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

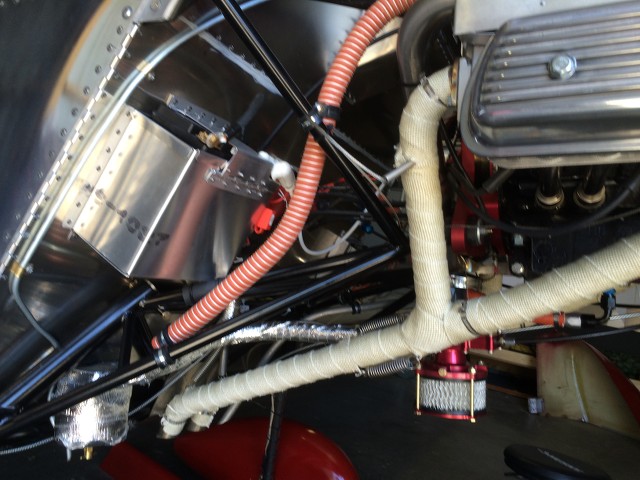

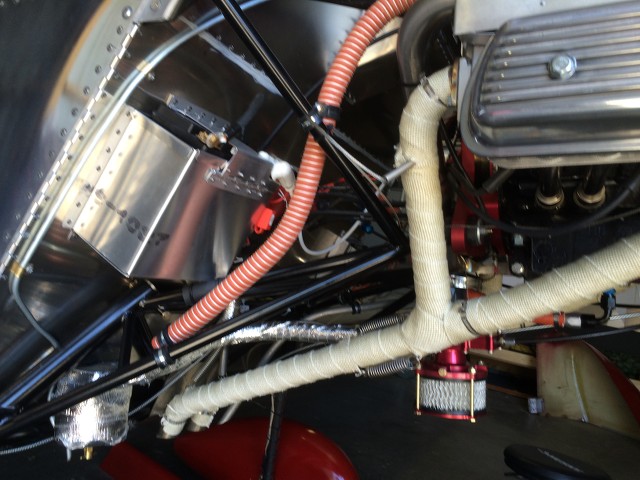

Re: Sonex 1534 Photos-40 hour testing phase

It has been a while since I posted an update on my plane. I am about 15 hours into the test phase. The airframe and engine have performed very well. I have had an issue with fuel vaporization I think. During my slow flight and power off stall testing I had an engine out event. My testing has been done above the airport. My airport has a tower and part of my testing was to go and talk to the controllers in the tower and brief them on my testing plan. Even though I am technically out of their airspace I remain on the tower frequency incase I have an issue such as this so I do not have to deal with the radio. The first thing I did since I was at the onset of a stall when the engine quit was to FLY the plane. I maintained best glide (what others have published) about 70 mph. radioed to the tower that I have an engine out and will be returning to the airport. I had plenty of time since I am a big fan of altitude. I also pulled the mixture to idle cut off and throttle to idle once I got control of the situation. After a short time maybe it was a minute I tried to restart the engine and it started. Reported to the tower that the engine has started and still coming in. I was able to make an uneventful landing and taxied back to the hanger to try to figure out what happened. I thought at first it may have been ice. I found nothing wrong with the fuel system or any part of the engine. I spoke to Sonex and they thought it could be a heat related problem. I do not want to remove the gascolator. So I went ahead and insulated the gascolator and fuel lines and ran a scat tube blasting cold air on the gascolator. Test flew and still had some minor heat issues. Then installed header wrap on the exhaust. Ground tested the engine and went flying for about an hour to heat things up. It was 89 degrees yesterday and I had no more fuel issues and the engine ran better than ever. The temps were a little hotter but the OAT was the highest I have flown the plane. I will be doing more testing to declare the issue is resolved.

My past flight training has always been based on safety. I have had many instructors because I like to get other CFI's teaching/flying styles. When I was doing my commercial instruction that instructor drilled emergency procedures into me. He also would tell me that with the commercial license I should strive to look and act like a professional if I wanted to be a professional. I think that the positive outcome of that day was due to all my instructors different training styles. But the one common theme was safety and emergency training.

My past flight training has always been based on safety. I have had many instructors because I like to get other CFI's teaching/flying styles. When I was doing my commercial instruction that instructor drilled emergency procedures into me. He also would tell me that with the commercial license I should strive to look and act like a professional if I wanted to be a professional. I think that the positive outcome of that day was due to all my instructors different training styles. But the one common theme was safety and emergency training.

Last edited by Gripdana on Wed Apr 29, 2015 2:28 pm, edited 1 time in total.

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Sonex 1534 Photos

Great job Dana! Good to hear the honest feedback on your flight testing.

Another reminder that for those of us that are hobby pilots (i,e. Not flying for a living) we can learn a lot from those that do.

Another reminder that for those of us that are hobby pilots (i,e. Not flying for a living) we can learn a lot from those that do.

Robbie Culver

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

-

Sonex1517 - Posts: 1670

- Joined: Fri Jun 03, 2011 10:11 am

- Location: T25 Aero Estates, Frankston, TX

Re: Sonex 1534 Photos

Dana,

Excellent writeup and pictures. It seems like it would be a good idea to do heat control from the beginning. Are you planning to fly to Oshkosh this year?

Excellent writeup and pictures. It seems like it would be a good idea to do heat control from the beginning. Are you planning to fly to Oshkosh this year?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Sonex 1534 Photos

I wanted to approach the heat if it came up. I did not want to over do things if it was not needed as others have the same set up and not had any issues. I'm not sure about OSH this year because I may not be able to get off work. If I do make out it will be a last minute decision.

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Re: Sonex 1534 Photos

Dana,

Excellent write up on your engine out and restart. Fantastic job flying the plane and handling the situation.

In reviewing your photos, one thing that I did was replace the 90 degree swivel fitting going to the AeroInjector with a solid 90 degree elbow fitting 1/8 NPT to 6an. That moved the fuel line about an inch farther away from the exhaust. I believe that solid elbow fitting was one of the better things I did to eliminate my heat issues.

The one I used was Earl's 982262 Blue Anodized Aluminum -6 AN Male to 1/8" NPT 90-Degee Elbow. I got it from Amazon Aircraft Supply (Amazon.com)

Thank you for sharing your lessons with all of us.

Jake

Excellent write up on your engine out and restart. Fantastic job flying the plane and handling the situation.

In reviewing your photos, one thing that I did was replace the 90 degree swivel fitting going to the AeroInjector with a solid 90 degree elbow fitting 1/8 NPT to 6an. That moved the fuel line about an inch farther away from the exhaust. I believe that solid elbow fitting was one of the better things I did to eliminate my heat issues.

The one I used was Earl's 982262 Blue Anodized Aluminum -6 AN Male to 1/8" NPT 90-Degee Elbow. I got it from Amazon Aircraft Supply (Amazon.com)

Thank you for sharing your lessons with all of us.

Jake

-

SonexN76ET - Posts: 494

- Joined: Tue Aug 27, 2013 2:39 pm

- Location: Atlanta

Who is online

Users browsing this forum: No registered users and 21 guests