random user submitted photo

Implementing XNS-SB-001 During Build

12 posts

• Page 1 of 2 • 1, 2

Implementing XNS-SB-001 During Build

We are riveting together the tail cone box on our project, and came to a sticking point when trying to set the aft-most line of vertical rivets – the ones that hold the back end of the side skins to the rudder post assembly. We received the extra doubler plate to accomplish the Mandatory Service bulletin along with our kit, and dutifully constructed the tail post with it incorporated (BTW, the hardware list has not been updated, so you better have an assortment of AN3 bolts so that you can upsize those that need to be longer) in the assembly. All was fine until we tried to set those two lines of rivets – and found that the extra doubler interferes with the un-pulled rivets. If you try to cheat the rivets in by pushing the factory heads in while upsetting the rivet, the shank swells before you can get them flush – so that’s a No Go.

The instructions on the Service Bulletin appear to be for a completed airplane that already has these rivets in place, and I noodled over the problem for a few days before finally deciding that the only way to do this right is to remove the plate (fifteen bolts, all of the nuts inside the tail cone), then set the rivets, and then replace the plate – in essence, doing the mod as if it was a completed airplane. It would have been nice to know that before I fully assembled the tail-post….. Oh well!

We have the plate removed right now, will pull the rivets, then reinstall – that should finish up the tail cone box, and we can move on to the turtledeck.

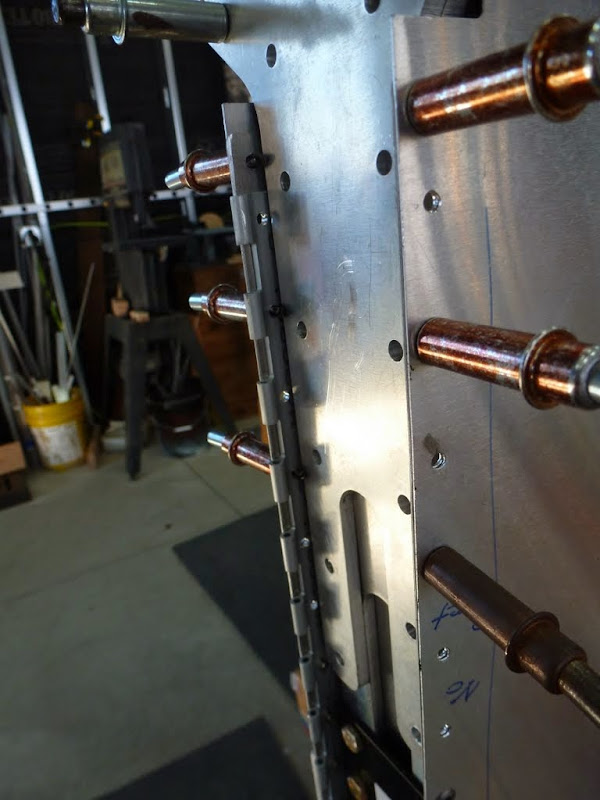

This is with the doubler plate still in place, with all but one of the bolts removed. The rivet holes all line up with the center of the doubler, so it stops you from inserting the unpulled rivets fully:

With the doubler plate removed, you can now see the tips of the clecos in the holes – and the rivets should insert fully before pulling:

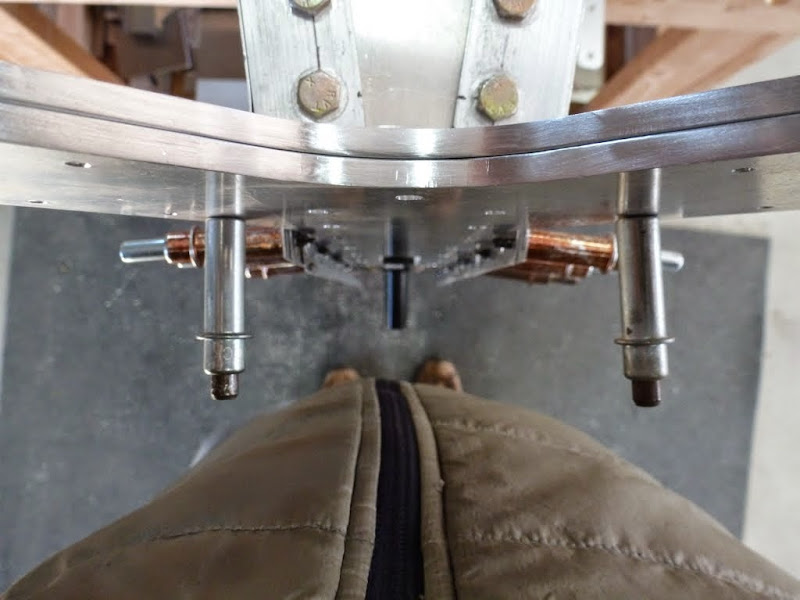

View looking down with the doubler plate removed – it is easier to see how the rivet holes line up with the plate in this view:

Hopefully, the pulled rivets won’t be so long as to interfere with getting the plate in place (the Service Bulletin instructions talk about prying the sheet metal out of the way to allow it to clear the rivets – we’ll see if that is necessary). I have considered squeezing solid rivets in those holes, as the shop head side would be shorter than with pulled rivets – but it looks like it will probably be OK with pulled rivets, and I think that the Cherry’s, with steel mandrels, are stronger than aluminum solids. This looks like an important area to get right!

Paul

The instructions on the Service Bulletin appear to be for a completed airplane that already has these rivets in place, and I noodled over the problem for a few days before finally deciding that the only way to do this right is to remove the plate (fifteen bolts, all of the nuts inside the tail cone), then set the rivets, and then replace the plate – in essence, doing the mod as if it was a completed airplane. It would have been nice to know that before I fully assembled the tail-post….. Oh well!

We have the plate removed right now, will pull the rivets, then reinstall – that should finish up the tail cone box, and we can move on to the turtledeck.

This is with the doubler plate still in place, with all but one of the bolts removed. The rivet holes all line up with the center of the doubler, so it stops you from inserting the unpulled rivets fully:

With the doubler plate removed, you can now see the tips of the clecos in the holes – and the rivets should insert fully before pulling:

View looking down with the doubler plate removed – it is easier to see how the rivet holes line up with the plate in this view:

Hopefully, the pulled rivets won’t be so long as to interfere with getting the plate in place (the Service Bulletin instructions talk about prying the sheet metal out of the way to allow it to clear the rivets – we’ll see if that is necessary). I have considered squeezing solid rivets in those holes, as the shop head side would be shorter than with pulled rivets – but it looks like it will probably be OK with pulled rivets, and I think that the Cherry’s, with steel mandrels, are stronger than aluminum solids. This looks like an important area to get right!

Paul

Paul Dye

"Ironflight"

Building a Xenos!

"Ironflight"

Building a Xenos!

- Ironflight

- Posts: 25

- Joined: Fri Sep 19, 2014 12:18 pm

Re: Implementing XNS-SB-001 During Build

Paul,

I had to bend out the aft part of the side skins with seaming pliers to be able to set the rivets. When I ran into the issue I asked the group and the consensus was bend the skins out like the SB says. It is tight otherwise!

Edit: here is my thread on the subject.

viewtopic.php?f=15&t=785

I had to bend out the aft part of the side skins with seaming pliers to be able to set the rivets. When I ran into the issue I asked the group and the consensus was bend the skins out like the SB says. It is tight otherwise!

Edit: here is my thread on the subject.

viewtopic.php?f=15&t=785

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Implementing XNS-SB-001 During Build

Thanks for the reply Bryan. I really didn't feel I could pry those flanges far enough out of the way to insert the -42 rivets without putting a permanent bend in the skins. I pulled the rivets just now, and put the plate back in place. Will have to fidget with a couple of the nuts to get them back on, but I'd guess a half hour should see them all torqued back the way they should be.

At least the tail wasn't installed and in the way!

At least the tail wasn't installed and in the way!

Paul Dye

"Ironflight"

Building a Xenos!

"Ironflight"

Building a Xenos!

- Ironflight

- Posts: 25

- Joined: Fri Sep 19, 2014 12:18 pm

Re: Implementing XNS-SB-001 During Build

Paul,

My skins have a permanent bend. I bent as minimally as possible and flexed the skin & flange out temporarily where it was tightest. From my thread you may have noted that at least one or two folks were able to setthe rivets with no permanent bend, but I did not see how I could. If you can get them set without the bend, it will look better! In truth though I don't think it came out poorly withthe bend.

My skins have a permanent bend. I bent as minimally as possible and flexed the skin & flange out temporarily where it was tightest. From my thread you may have noted that at least one or two folks were able to setthe rivets with no permanent bend, but I did not see how I could. If you can get them set without the bend, it will look better! In truth though I don't think it came out poorly withthe bend.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Implementing XNS-SB-001 During Build

All done - it probably took a total of an hour to pull the plate off, set the rivets, and then get the plate back where it belonged - and there are no signs at all of bending the skins - they are nice and smooth. I probably spent way more time trying to figure out how to do the rivets without pulling the plate off than I eventually did just biting the bullet and doing it the way I did, and the results are very nice. I used a combination of extensions on the socket wrench to get the nuts back on, and it was very simple.

Paul Dye

"Ironflight"

Building a Xenos!

"Ironflight"

Building a Xenos!

- Ironflight

- Posts: 25

- Joined: Fri Sep 19, 2014 12:18 pm

Re: Implementing XNS-SB-001 During Build

Hi there,

A further iteration on the incorporation of XNS-SB-001 during build is to use solid rivets in place of the pop rivets. I built mine up using the AN470 AD 4-4 rivets (and countersunk solid in the lower section) and a hand rivet squeezer (I have a pneumatic but the hand one is a little more precise). These items are ones I was using in another project. The tail of the squeezed rivet being just 1/16 inch high allows them to clear the SB-001 mod, even on the left side that has the rudder hinge, without any bending out of the side skins. I did use a rubber grommet under the squeezer on the tail side to keep the skins firmly together. The 4-4 worked on both sides, although the hinge adds to the thickness, the manufactured head is still within limits. I got the initial idea of doing this from another posting on this site - my build was a little tedious as I built up the Y tail with all the brackets and pre-assembled everything including the stabilators to be sure it would all fit on final assembly - drilling the angle cross piece under the hockey sticks after everything else was bolted in place. And then diassembling all the fittings on the tail section to squeeze the rivets.

I anyone would like to see some photos I'll include them if someone can explain how!

Brian Rebbechi Xenos #0058

Welshmans Reef VIC

Australia

A further iteration on the incorporation of XNS-SB-001 during build is to use solid rivets in place of the pop rivets. I built mine up using the AN470 AD 4-4 rivets (and countersunk solid in the lower section) and a hand rivet squeezer (I have a pneumatic but the hand one is a little more precise). These items are ones I was using in another project. The tail of the squeezed rivet being just 1/16 inch high allows them to clear the SB-001 mod, even on the left side that has the rudder hinge, without any bending out of the side skins. I did use a rubber grommet under the squeezer on the tail side to keep the skins firmly together. The 4-4 worked on both sides, although the hinge adds to the thickness, the manufactured head is still within limits. I got the initial idea of doing this from another posting on this site - my build was a little tedious as I built up the Y tail with all the brackets and pre-assembled everything including the stabilators to be sure it would all fit on final assembly - drilling the angle cross piece under the hockey sticks after everything else was bolted in place. And then diassembling all the fittings on the tail section to squeeze the rivets.

I anyone would like to see some photos I'll include them if someone can explain how!

Brian Rebbechi Xenos #0058

Welshmans Reef VIC

Australia

- brian_rebbechi

- Posts: 7

- Joined: Wed Mar 04, 2015 3:00 am

Re: Implementing XNS-SB-001 During Build

Hi there,

Attached are some photos of the solid riveting for SB-001

Attached are some photos of the solid riveting for SB-001

- Attachments

-

- tail section before re-assembly. Note rivet shop head (tail) only 1/16 inch

- S5000200 resize2.jpg (111.45 KiB) Viewed 9868 times

-

- S5000215 resize2.jpg (119.09 KiB) Viewed 9868 times

-

- S5000216 resize 2.jpg (132.01 KiB) Viewed 9868 times

- brian_rebbechi

- Posts: 7

- Joined: Wed Mar 04, 2015 3:00 am

Re: Implementing XNS-SB-001 During Build

As a Waiex builder I still don't see how you guys can get those nuts on and torqued after the channel is riveted in. Looks good!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Implementing XNS-SB-001 During Build

Bryan,

Thanks for the kind words. You're right that its tricky to get all the nuts torqued - I used a combination of some long extensions (built up to 12" or more for my 1/4" drive socket set), a small (accurate) 7" long torque wrench. It was aided by leaving out a couple of the side pieces on the forward tail wheel tube attach, until the aft most pieces were done. Actually the most difficult to torque were the attach brackets on the lower longerons. As a footnote, if using solid rivets, I would recommend using a hand rivet squeezer (Avery or like) rather than a rivet gun and bucking bar, as due to the slightly inward angle of the rivets, it doesn't lend itself to a bucking bar suitable to react the 1/8" rivets. And a rubber grommet around the tail of the rivet before squeezing, helps to keep the skin and channel close together- solid rivets don't seem to pull the skins together naturally like the pop rivets appear to.

Brian Rebbechi Xenos #0058

Thanks for the kind words. You're right that its tricky to get all the nuts torqued - I used a combination of some long extensions (built up to 12" or more for my 1/4" drive socket set), a small (accurate) 7" long torque wrench. It was aided by leaving out a couple of the side pieces on the forward tail wheel tube attach, until the aft most pieces were done. Actually the most difficult to torque were the attach brackets on the lower longerons. As a footnote, if using solid rivets, I would recommend using a hand rivet squeezer (Avery or like) rather than a rivet gun and bucking bar, as due to the slightly inward angle of the rivets, it doesn't lend itself to a bucking bar suitable to react the 1/8" rivets. And a rubber grommet around the tail of the rivet before squeezing, helps to keep the skin and channel close together- solid rivets don't seem to pull the skins together naturally like the pop rivets appear to.

Brian Rebbechi Xenos #0058

- brian_rebbechi

- Posts: 7

- Joined: Wed Mar 04, 2015 3:00 am

Re: Implementing XNS-SB-001 During Build

Is there any good reason one could not install nutplates on the forward / aft spar attach points?

- Xenos helper

- Posts: 4

- Joined: Tue Jan 20, 2015 1:58 pm

12 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 8 guests