Page 1 of 3

Intermittent engine operation

Posted:

Sun Aug 30, 2020 1:29 pmby gethomas

Can't get recently completed Aerovee2.1/AeroInjector running correctly. With tunning I now have set, engine starts easily, runs smoothly, and takes full throttle without balking. Doing ground runs with cowling on, everything is ok until engine heats up (CHT 280up). Then engine quits when throttle is less than 1/2 open. It restarts easily but will not continue running at low throttle.

Any ideas on what's going on?

Re: Intermittent engine operation

Posted:

Sun Aug 30, 2020 6:57 pmby Curry Matherne

Do you have heat shielding on your fuel lines? Possible vapor lock??

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 9:02 amby gethomas

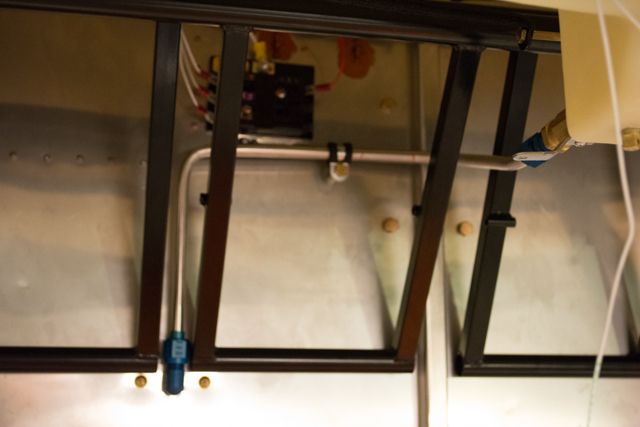

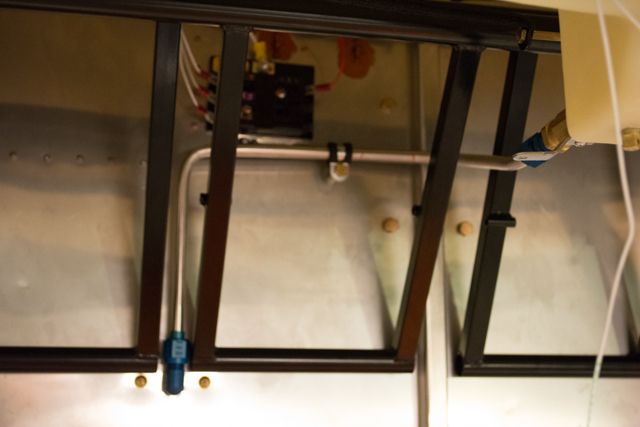

Picture of my installation and installation shown in AeroVee manual.

- FactoryInstallation.JPG (61.42 KiB) Viewed 3839 times

Do you think heating is a problem with my line located as shown (similar to manual)?

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 9:34 amby XenosN42

Hi,

What you are going through must be very frustrating. Have you considered reaching out to someone in your area that has successfully built and flown an AeroVee? I bet there is someone who would fly or drive over to help you out. The Sonex community wants to see everyone succeed. Look at the builder directory on the Sonex site, post here and on the Facebook site if you are a member.

The following is a real story.

A builder at my airport was about to do his first AeroVee engine start. I’m there a lot, but he rarely was. But just so happened we were there at the same time. I looked everything over, helped him adjust the AeroInjector and the engine ran great.

Then I didn’t see him for about 1-1/2 years. My first question: “How’s it running”. Answer, “I haven’t been able to start it in about 14 months.” He then lists all the things he’s done to try to get it to work. I say “well it should still run let me give it a try”. I poked and prodded the engine for about 10 minutes. I didn’t find anything major but I did find one minor problem. I told the builder that most likely the problem wasn’t keeping the engine from running, but since it would only take 2 minutes to fix let’s do that and try again.

Well I was wrong. We fixed that minor problem and the engine fired up and ran perfectly. What was the problem? Doesn’t matter. What is important is to get a fresh pair of experienced eyes directly on your engine.

Just my 2 cent opinion and worth less than that.

BTW – Wrap those exhaust pipes.

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 12:38 pmby Matt541

I'll echo what what Michael said, wrap those exhaust pipes.

FWIW, the previous owner of my Sonex had what sounds like a very similar issue to yours. He ditched the gascolator and went to an inline filter, then wrapped the fuel lines with fire sleeve, insulation and reflective aluminum tape. Never had the issue again. Not saying that's it for you, or if that's the correct way to do it, just what I know someone else did.

YMMV

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 4:22 pmby pappas

I also went without a gascolator. I ran the fuel line from the firewall directly to the Aeroinjector. Firesleeve the fuel line, make sure it is routed as far from the exhaust as you can get it, and wrap the exhaust. Make sure that the Aeroinjector is the lowest point in the ful system.

These are just starting guidelines. Don't worry that the CHT's get to 280 deg f, Sonex gives us 420 or 425, (can't remember exactly), for 5 minutes! they will be hot until you get probably 50 hours on the engine in the air.

I also had problems with the engine dying after landing if I reduced the throttle too much with the mixture full rich. It worked itself out with additional hours, more familiarity on my part with the system, tweaking the mixture and idle settings with smaller and smaller adjustments, and landing with slightly lean mixture. Frustrating, I know, but you will get it.

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 5:42 pmby mike.smith

pappas wrote:I also went without a gascolator. I ran the fuel line from the firewall directly to the Aeroinjector. Firesleeve the fuel line, make sure it is routed as far from the exhaust as you can get it, and wrap the exhaust. Make sure that the Aeroinjector is the lowest point in the ful system.

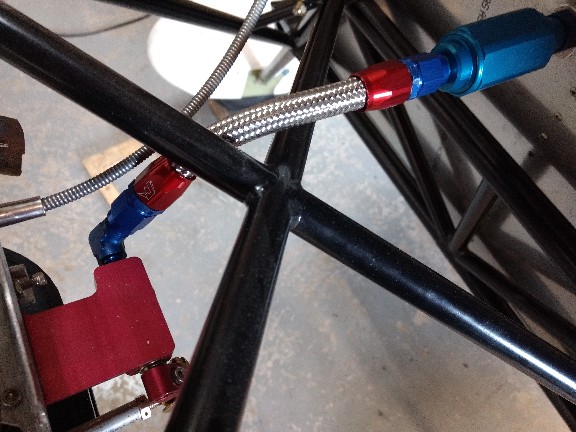

I agree completely. Ditch the gascolator, firesleeve the fuel line (I have another layer of insulation around the firesleeve), and wrap the exhaust. An exposed fuel line next to an unprotected exhaust is asking for a lot of trouble.

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 7:38 pmby Rynoth

The first thing I noticed looking at the pics is the fuel line from the firewall TO the gascolator. The plans setup has all lines leading up to the gascolator in the cockpit, with only the line from gascolator-to-carb in the engine compartment. That extra 8 inches of aluminum tube fuel line in the engine compartment leading to the gascolator is probably adding extra heat to the fuel. I'd look at changing that, along with wrapping the fuel line and perhaps exhaust as well.

I've never had any sort of vapor lock issues with the plans fuel line setup with gascolator, wrapped exhaust and wrapped fuel line, Aerovee Turbo. I think the stock Aerovee has the carb/fuel routing a bit closer to exhaust pipes though.

Re: Intermittent engine operation

Posted:

Mon Aug 31, 2020 8:20 pmby Bryan Cotton

Mine hasn't run yet. But I may have the shortest run ever.

viewtopic.php?f=39&t=578&start=1010And on the page after my link, there are pictures before firesleeve.

Re: Intermittent engine operation

Posted:

Tue Sep 01, 2020 4:52 amby NWade

As others have mentioned: It is important that the Aeroinjector is the *lowest* point in the fuel system. From the photos you showed, it appears that your gascolator is lower than the Aeroinjector. That is going to cause lots of problems. First, any bubbles or vapor will get trapped in the system with that layout. Second, by forcing the fuel to run “uphill” after the gascolator you may see dramatic losses in fuel flow as your tank empties out.

I’d advise doing as others mentioned and ditching the gascolator. Fire-sleeving the lines might also be a good idea. But *also* move the lines and/or the aeroinjector itself to sit as low in the cowling as you can. This will maximize “head pressure” from the tank in addition to helping guarantee a downhill run all the way from the tank to the needle.

From page 6 of the AeroInjector manual (available for download from the AeroConversions website):

“The ideal mounting position for an AeroInjector is in the up- draft configuration, as low as possible, to assure constant gravity fuel flow even in extreme nose high attitudes.”

—Noel