random user submitted photo

Bending 1/4 in aluminum stock?

10 posts

• Page 1 of 1

Bending 1/4 in aluminum stock?

I am working on page WXB-F23 (Waiex tail parts). It has several calls for bending 1/4 in thick parts 5 degrees. Now, we are supposed to be able to build without any special equipment… What have others done to make the bends of such thick parts? Danke Steve J

- sjakulski

- Posts: 60

- Joined: Mon Mar 22, 2021 8:35 am

Re: Bending 1/4 in aluminum stock?

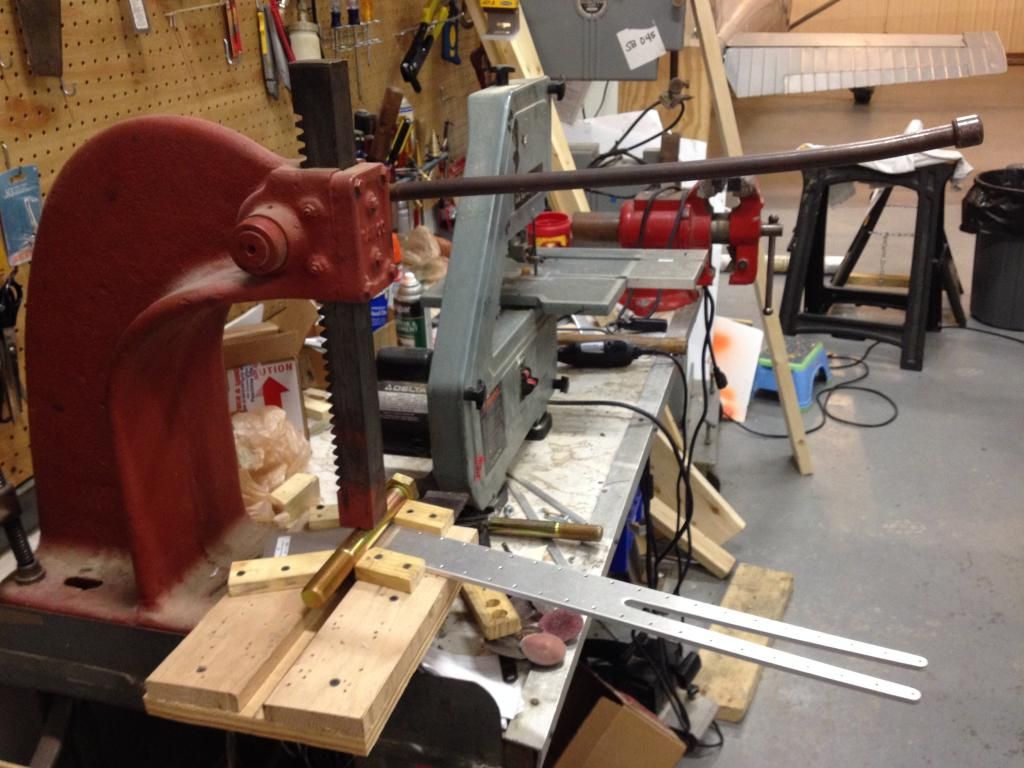

I used an arbor press

Hopefully the Photobucket image still sort of works. Else there is an earlier version in the first couple pages of my thread.

viewtopic.php?f=39&t=578

Hopefully the Photobucket image still sort of works. Else there is an earlier version in the first couple pages of my thread.

viewtopic.php?f=39&t=578

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Bending 1/4 in aluminum stock?

Harbor Frieght has a cheap press that I used to make

those small bends in thicker material.

those small bends in thicker material.

Peter Hoey

SEL Pvt, Comm Glider, CFIG, Pawnee & L19 Towpilot

Philadelphia Glider Council

Sonex B SNB0021, N561PH, Taildragger, Aerovee Turbo, MGL MX1, First flight Dec 18, 2022

Also built Sonerai IIL N86PH

SEL Pvt, Comm Glider, CFIG, Pawnee & L19 Towpilot

Philadelphia Glider Council

Sonex B SNB0021, N561PH, Taildragger, Aerovee Turbo, MGL MX1, First flight Dec 18, 2022

Also built Sonerai IIL N86PH

- pfhoeycfi

- Posts: 384

- Joined: Wed Jun 28, 2017 3:45 pm

Re: Bending 1/4 in aluminum stock?

sjakulski wrote:I am working on page WXB-F23 (Waiex tail parts). It has several calls for bending 1/4 in thick parts 5 degrees. Now, we are supposed to be able to build without any special equipment… What have others done to make the bends of such thick parts? Danke Steve J

Steve,

You will need more tools than Sonex mentions in their marketing material to build the kit. As a reference: https://www.sonexaircraft.com/required-tools/

In my experience, more tools are required than this. But the additional tools that I decided I needed are neither expensive nor hard to find.

Bending the "hockey sticks" was a profound moment for me in my Waiex A kit. It was the first time I had ever bent metal using a press, was at the very beginning of my build (as it seems for you), and was before I ever drove a single rivet.

You will need a press to bend the material. An arbor press or a hydraulic press will work.

I'll link my blog post with my first press bend here:

http://www.rynoth.com/wordpress/waiex/2 ... pennage-1/

Ryan Roth

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

-

Rynoth - Posts: 1308

- Joined: Fri Jul 26, 2013 1:32 pm

- Location: Knoxville, TN

Re: Bending 1/4 in aluminum stock?

I also did these at the beginning of the build. I thought I was close, but years later when I went to mount them they were way off. I ended up buying another tail kit since I didn't want to disassemble everything to get to the spars. Building them again was much quicker. I ended up finding a shop locally with press that could bend the spars and they fit perfectly (but I had to trim the skins a bunch). Not every place will have a nearby shop to do this.

- Zack

- Posts: 75

- Joined: Fri Nov 24, 2017 11:45 am

Re: Bending 1/4 in aluminum stock?

I am a hammer mechanic. Would it be too crude to use a hammer, vice and iPhone if jigged correctly? The hammer (with a wood protector) would "persuade" the metal into the correct angle. An iPhone can measure angles with .1 degree resolution.

Building electric Xenos

President, EAA Chapter 1250

President, EAA Chapter 1250

-

taildragger - Posts: 48

- Joined: Wed Aug 04, 2021 6:13 am

- Location: Pottstown, PA

Re: Bending 1/4 in aluminum stock?

taildragger wrote:I am a hammer mechanic. Would it be too crude to use a hammer, vice and iPhone if jigged correctly? The hammer (with a wood protector) would "persuade" the metal into the correct angle. An iPhone can measure angles with .1 degree resolution.

Visions of putting the iPhone between the workpiece and the hammer and pounding it into oblivion raced before my eyes - then I read the rest of your post! :-)

Graeme JW Smith

-

GraemeSmith - Posts: 939

- Joined: Sat May 18, 2019 8:58 am

- Location: RI

Re: Bending 1/4 in aluminum stock?

taildragger wrote:I am a hammer mechanic. Would it be too crude to use a hammer, vice and iPhone if jigged correctly? The hammer (with a wood protector) would "persuade" the metal into the correct angle. An iPhone can measure angles with .1 degree resolution.

Yes, too crude. Works fine for bending utility trailer parts. As you persuade the metal to bend with the hammer you are really not controlling where the bend takes place.

This thought process for building an airplane is rather scary to me.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Bending 1/4 in aluminum stock?

sjakulski wrote:I am working on page WXB-F23 (Waiex tail parts). It has several calls for bending 1/4 in thick parts 5 degrees. Now, we are supposed to be able to build without any special equipment… What have others done to make the bends of such thick parts? Danke Steve J

The Sonex Builders & Pilots Foundation has links to many great videos showing build techniques. One shows how to bend aluminum. https://sonexfoundation.com/safety-%26-education All the videos are short and should be worth your time. Enjoy.

-- Michael

OneX N169XE

author of the 'Flight Data Viewer'

OneX N169XE

author of the 'Flight Data Viewer'

- XenosN42

- Posts: 421

- Joined: Thu Jul 24, 2014 4:45 pm

- Location: PA, USA

Re: Bending 1/4 in aluminum stock?

I've used the vise and hammer method many times in my build. You need custom smooth vise jaws with an appropriate radius. You can use a block between the part and the hammer to get a uniform application of force and break the bend on the vise jaws. However, these spars are not suited to this method. They are too thick to get the precision you need. Later when you bolt them to the fuselage you cannot use the bolts to take up any gap, they need to be perfect. I had to replace my spars because of this and ended up building another tail kit because of the work required to open up the stabilators, remove the original spars, match drill them and install new ones was so great.

- Zack

- Posts: 75

- Joined: Fri Nov 24, 2017 11:45 am

10 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 27 guests