Stabilizers Complete!

We’ve been enjoying nice building weather out in our shop the past week or so, and are happy to report that we’ve gone as far as we can go on the tail surfaces at this time. With the Ruddervators and Rudder complete, and the stabilizers as far as we can get them without a fuselage on which to mount them, I guess it is time to move on to that fuselage. Looks like lots of little pieces to fabricate for the next few sessions.

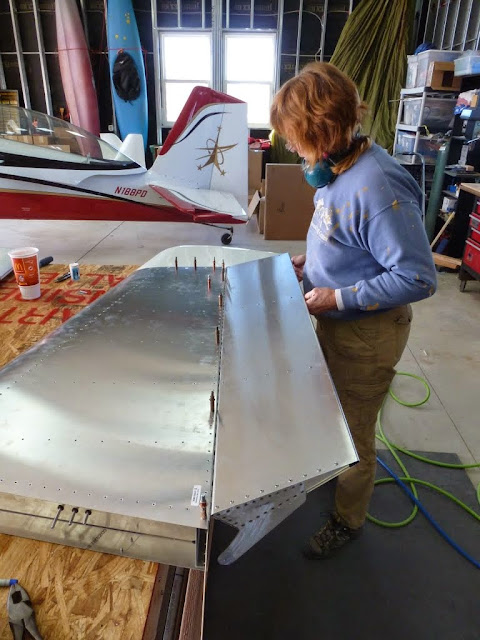

Right Stab complete – doing a fit check with the Ruddervator:

A very quick way to countersink the holes for the skin dimples that fit the screws to hold the tips on the stabs. We just use a countersink bit in a “suicide Mandrel” mounted in the hand drill. This is the final step after mounting the nutplates – the nutplates centers the countersink bit and acts as a stop when it has gone deep enough. The fit? Perfect!

The tip rib is easy to install with a few measurements and some clecos:

Paul

Right Stab complete – doing a fit check with the Ruddervator:

A very quick way to countersink the holes for the skin dimples that fit the screws to hold the tips on the stabs. We just use a countersink bit in a “suicide Mandrel” mounted in the hand drill. This is the final step after mounting the nutplates – the nutplates centers the countersink bit and acts as a stop when it has gone deep enough. The fit? Perfect!

The tip rib is easy to install with a few measurements and some clecos:

Paul