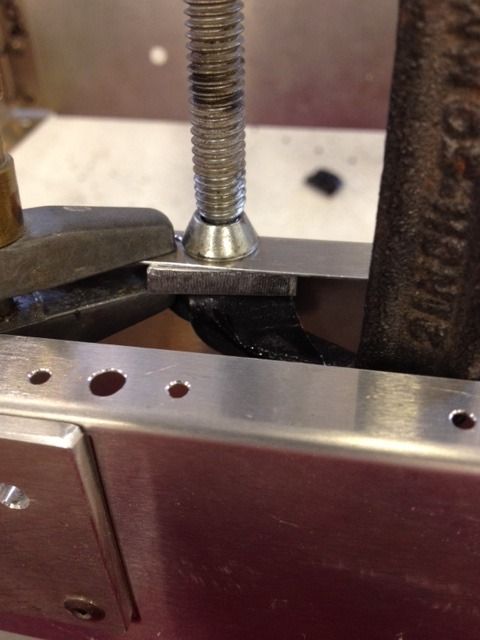

Dimpling in tight places

On my mini rudder, the skin rivets were lined up with the bottom rivets and it looked like I would have an interference when I went to pull the rivets. I decided to use flush AN rivets on the one row of the drive horn. 3 of those rivets went through a forward rib that would need to be dimpled, but the holes were way too close to the radius to get a dimple die. I used a 100 degree pop rivet dimpler half and a #6 screw. It came out slightly over dimpled but good. Maybe using a rivet as the male die would have worked. I used a flush set against the screw head and nothing but the female dimple die on the other side.