random user submitted photo

Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

So here is my technique for drilling the critical 1/4" tail hold down holes. First I took out the rivets at the front corners of the shear panel (by the green arrows).

Then I clecoed down my tail mount angle, put a scrap piece of angle behind, and clamped them together:

Brought the two angles over to the vise and transferred the holes using my 3/16" HF transfer punch:

I shot those 6 holes on the drill press, clecoed the angles back together, and clecoed them down using the two holes that want to become 1/4" tail hold downs. I then transferred the holes from the spots where I removed the rivets. That scrap angle now becomes a tool to hold the lower tail mount angle:

Here are all the clecoes in:

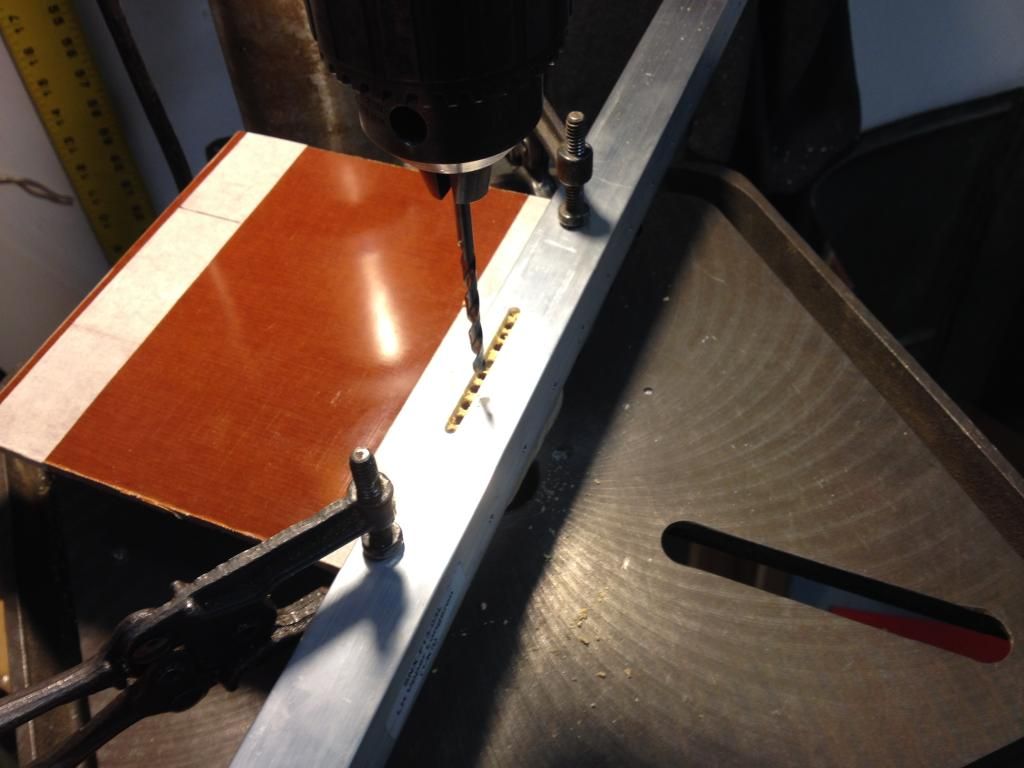

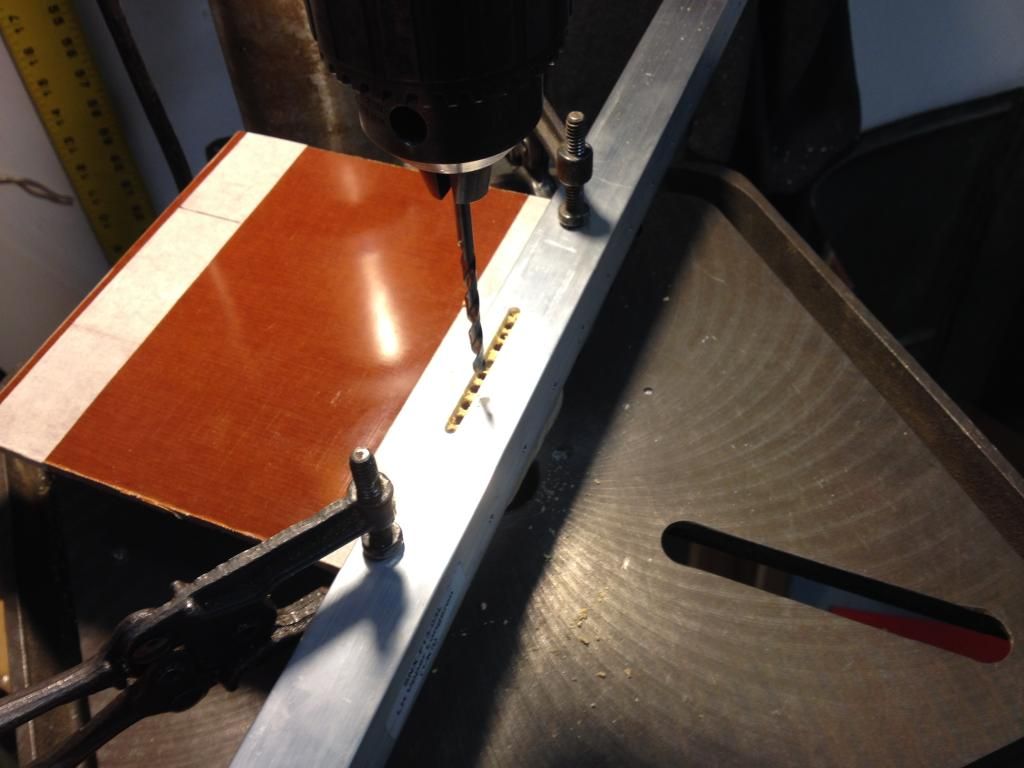

Now I bring up the hole in the block and angle to the next size. In this case I am going from #40 to #30:

The block and angle now act as a 1" thick guide block to drill the longeron, shear panel, and the angle underneath.

It's almost too easy. For all these holes I have been averaging one hour per hole to final size. Much better than rebuilding the tail. Almost forgot to mention, I used some aluminum pops to rivet the shear panel to the angle underneath temporarily. The angle is clecoed to the verticals underneath. I will take the angle out to deburr then it goes back in for keeps.

Then I clecoed down my tail mount angle, put a scrap piece of angle behind, and clamped them together:

Brought the two angles over to the vise and transferred the holes using my 3/16" HF transfer punch:

I shot those 6 holes on the drill press, clecoed the angles back together, and clecoed them down using the two holes that want to become 1/4" tail hold downs. I then transferred the holes from the spots where I removed the rivets. That scrap angle now becomes a tool to hold the lower tail mount angle:

Here are all the clecoes in:

Now I bring up the hole in the block and angle to the next size. In this case I am going from #40 to #30:

The block and angle now act as a 1" thick guide block to drill the longeron, shear panel, and the angle underneath.

It's almost too easy. For all these holes I have been averaging one hour per hole to final size. Much better than rebuilding the tail. Almost forgot to mention, I used some aluminum pops to rivet the shear panel to the angle underneath temporarily. The angle is clecoed to the verticals underneath. I will take the angle out to deburr then it goes back in for keeps.

Last edited by Bryan Cotton on Sun Sep 07, 2014 9:06 am, edited 1 time in total.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Looking great Bryan. I must say that tail assembly is much more complicated on the Waiex then the Sonex.

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton Waiex 191 - N191YX

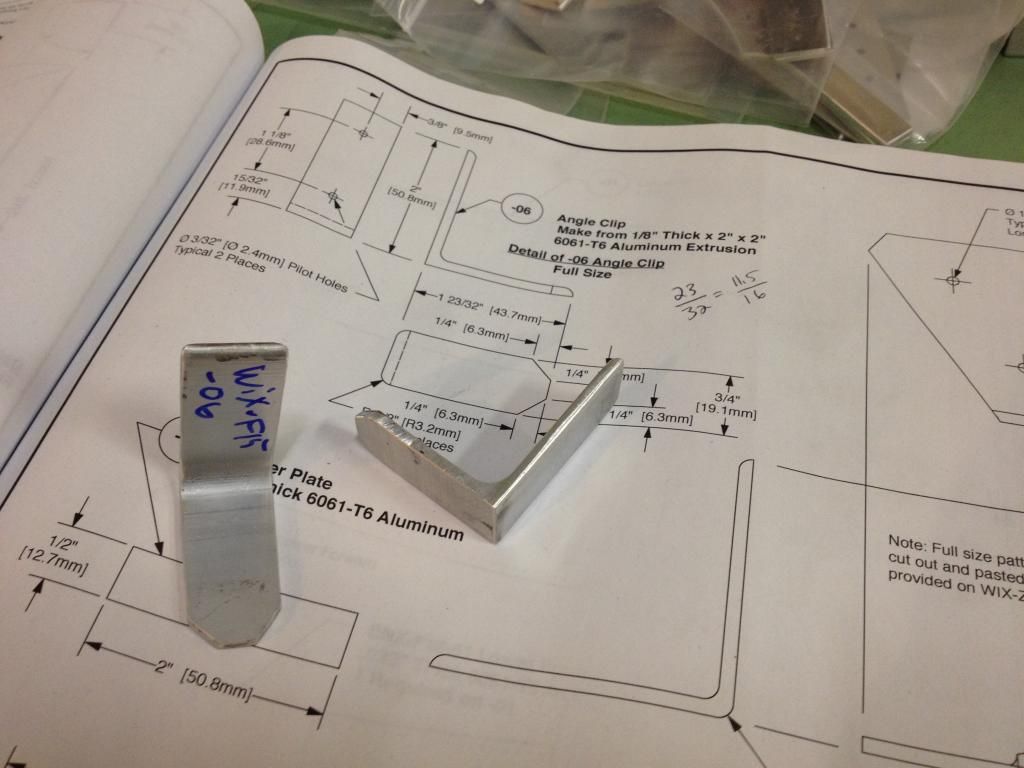

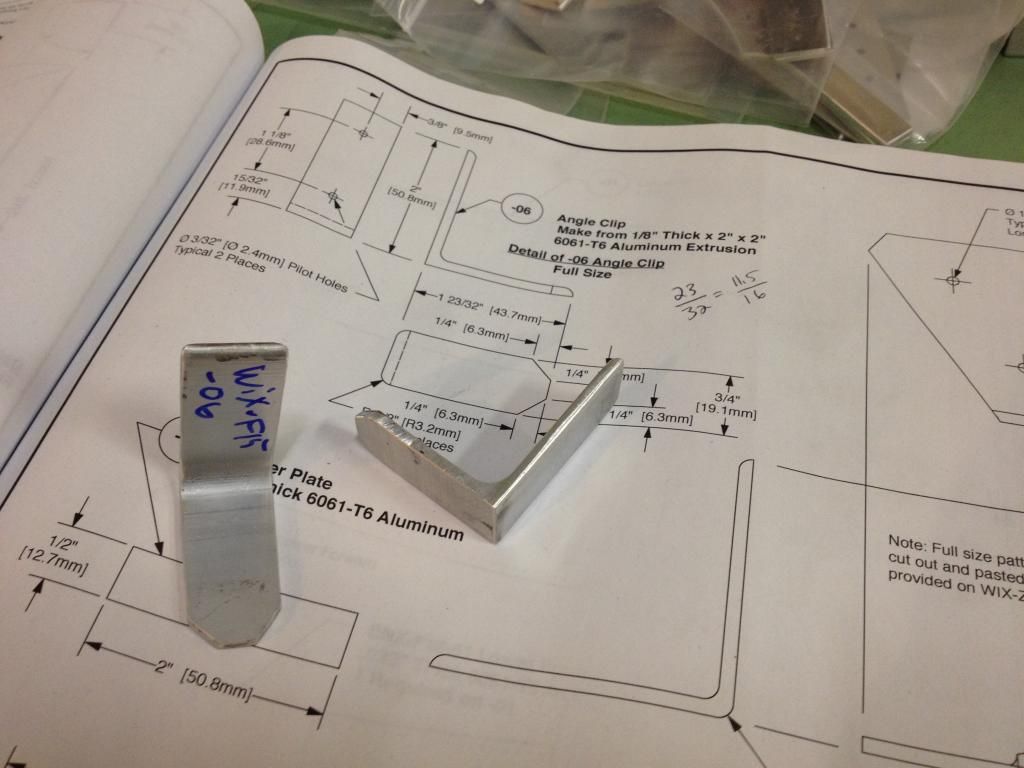

This weekend I got very little done. Cleaning and organizing of the hangar, fixing a couple cabinets and home, and I made these two angle clips:

I looked for these clips for a long time before I realized I had to make them.

I looked for these clips for a long time before I realized I had to make them.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

FYI on those clips.. you will probably need to radius one of the edges a lot more than what the plans show... the plans seem to assume that the inner radius of all the angles is 1/8", but on all the angle that has flanges larger than 1", the inside corner radius is more like 3/16". You'll see what I mean when it's time to locate those clips and they won't quite sit flush on the inside of another angle.

There are several other instances where this happens in the fwd fuselage, anytime one part nests in the inside angle of another part.

There are several other instances where this happens in the fwd fuselage, anytime one part nests in the inside angle of another part.

Ryan Roth

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

-

Rynoth - Posts: 1308

- Joined: Fri Jul 26, 2013 1:32 pm

- Location: Knoxville, TN

Re: Cotton Waiex 191 - N191YX

Thanks. Glad I skipped setting up the router and just laid to it with the angle sander instead.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Rynoth wrote:FYI on those clips.. you will probably need to radius one of the edges a lot more than what the plans show... the plans seem to assume that the inner radius of all the angles is 1/8", but on all the angle that has flanges larger than 1", the inside corner radius is more like 3/16". You'll see what I mean when it's time to locate those clips and they won't quite sit flush on the inside of another angle.

There are several other instances where this happens in the fwd fuselage, anytime one part nests in the inside angle of another part.

I think you will find that on all Sonex / Waiex parts, that they were drawn when the inside radius of standard extruded angles was smaller than today, and more material must be removed from parts that nest in them than shown.

David A.

- DCASonex

- Posts: 935

- Joined: Mon Sep 12, 2011 8:04 pm

- Location: Western NY USA

Re: Cotton Waiex 191 - N191YX

David,

My observation has been that the 1" angles have the small radius, and the wider angles have the larger radius. I remade my lower tail mount angle from some leftover 1/8" thick 1.5" wide stock that I bought for my hummelbird in the 1990's. Those angles, as well as the larger angles in the Waiex kit seem to have a 1/16"-ish radius.

My observation has been that the 1" angles have the small radius, and the wider angles have the larger radius. I remade my lower tail mount angle from some leftover 1/8" thick 1.5" wide stock that I bought for my hummelbird in the 1990's. Those angles, as well as the larger angles in the Waiex kit seem to have a 1/16"-ish radius.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Here is my technique for getting the hole for the flap pivot blocks centered and perpendicular to the bolt holes.

First I put a piece of white masking tape over the inside face of the block. With a couple of long 3/16" bolts sticking through I draw parallel lines on the outside of the bolts:

Then I use another ruler to make lines a fixed distance from each bolt. These lines give me a good way to find the center. It is easier to measure to a line than a hole.

Finally I transfer that midpoint measurement up to the edge and draw a line across where I need to holesaw.

You can see I use 4 bolts to make the holes level with the plane of the vise. Long 3/16" rods would be better.

First I put a piece of white masking tape over the inside face of the block. With a couple of long 3/16" bolts sticking through I draw parallel lines on the outside of the bolts:

Then I use another ruler to make lines a fixed distance from each bolt. These lines give me a good way to find the center. It is easier to measure to a line than a hole.

Finally I transfer that midpoint measurement up to the edge and draw a line across where I need to holesaw.

You can see I use 4 bolts to make the holes level with the plane of the vise. Long 3/16" rods would be better.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Here is how I tweak a holesaw size down a little bit:

I am going for that nice fit for the flap drive blocks.

I am going for that nice fit for the flap drive blocks.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

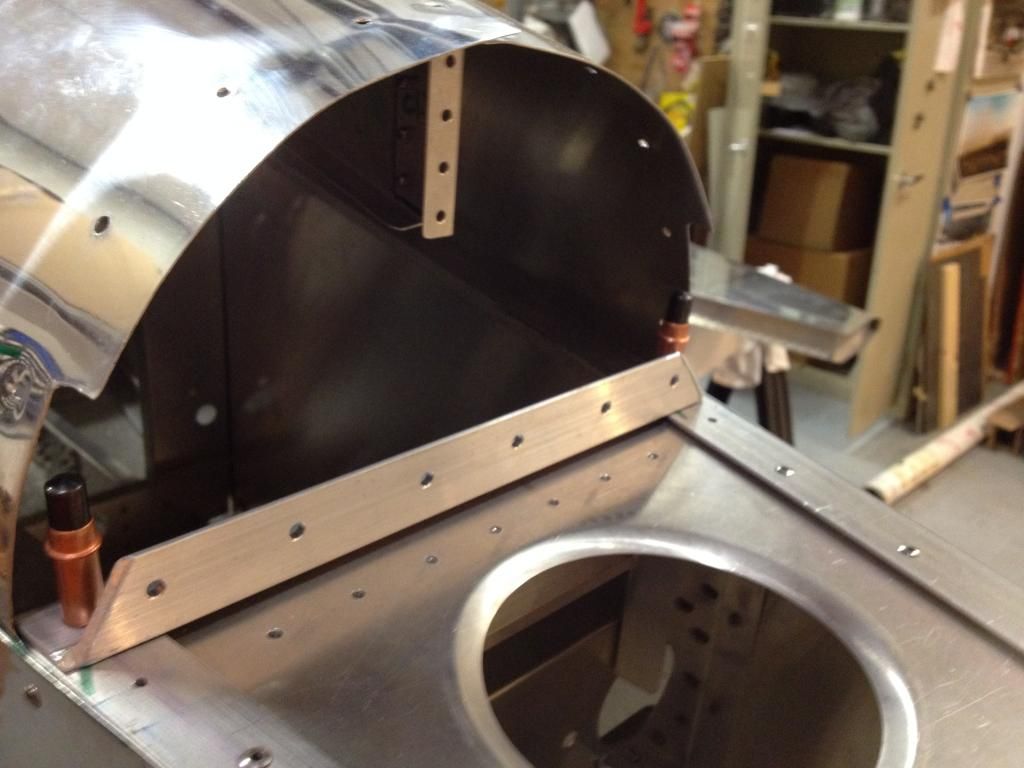

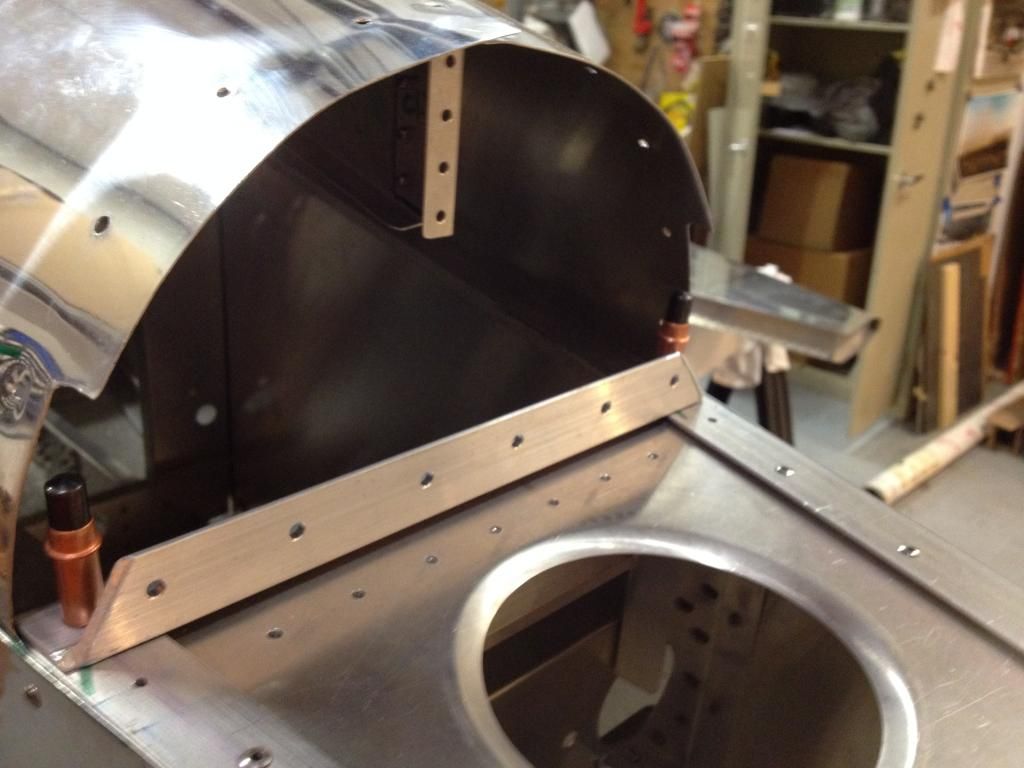

Here I am working on the striker plates. I rounded off the edges with a 1/8"R router bit first.

I drilled a bunch of holes. Then I chocked up a little high speed dremel cutting tool in the drill press, turned the speed up to 3100 RPM, set up a fence, and connected the dots. Didn't get a picture. Finished it with a file. Here they are clecoed on.

I am getting close to forward fuselage assembly.

I drilled a bunch of holes. Then I chocked up a little high speed dremel cutting tool in the drill press, turned the speed up to 3100 RPM, set up a fence, and connected the dots. Didn't get a picture. Finished it with a file. Here they are clecoed on.

I am getting close to forward fuselage assembly.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5493

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Who is online

Users browsing this forum: No registered users and 6 guests