random user submitted photo

Scott's Sonex 1629 - N629SX

Re: Scott's Sonex #1629 - Progress

Michael,

Thanks for the comments. I had seriously considered leaving the floor off, but with my panel "ahead of schedule, and fuel tank already pre-fitted with glareshield, I went ahead and close the floor up.

The biggest contributing factor to this decision is I decided to stay with the tri-gear arrangement, and the floor is not removable with the main gear legs installed. I know you can remove them and then the floor, but I made the decision to rivet the floor on. The rear fuselage bottom skin is still off and will remain off until finishing!

Thanks for the comments. I had seriously considered leaving the floor off, but with my panel "ahead of schedule, and fuel tank already pre-fitted with glareshield, I went ahead and close the floor up.

The biggest contributing factor to this decision is I decided to stay with the tri-gear arrangement, and the floor is not removable with the main gear legs installed. I know you can remove them and then the floor, but I made the decision to rivet the floor on. The rear fuselage bottom skin is still off and will remain off until finishing!

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Scott's Sonex #1629 - Progress

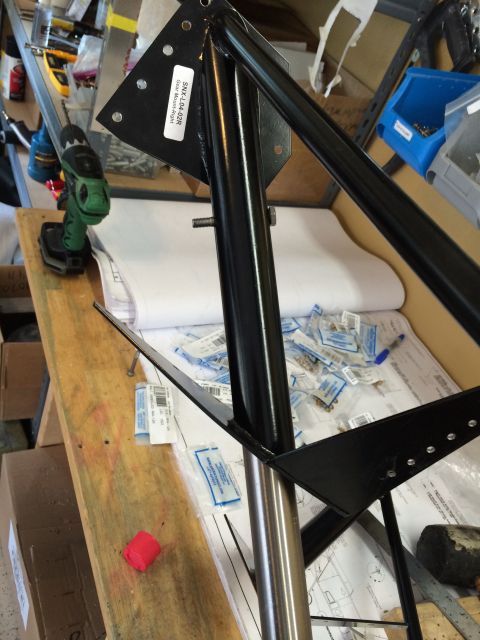

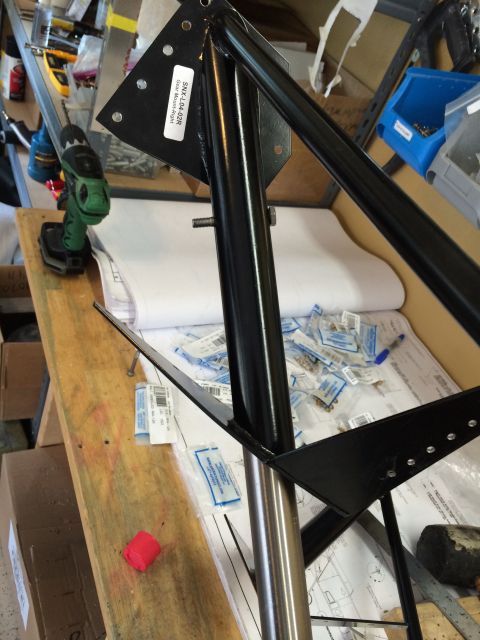

The nose gear is drilled and fitted. This probably looks strange to all of you taildragger's out there!

Working on the main gear weldments now. The carbon steel is two layers thick and the pilot hole for titanium leg retaining bolt is nuts to drill. Need some different drill bits, will try again tomorrow.

Working on the main gear weldments now. The carbon steel is two layers thick and the pilot hole for titanium leg retaining bolt is nuts to drill. Need some different drill bits, will try again tomorrow.

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Scott's Sonex #1629 - Progress

Main gear weldments are drilled thru the titanium main gear legs. That was a challenge, but have figured out the tricks for working with TI. Which is good because I still have the axles to drill and mount. The drill press is your friend. Lots and lots of cutting fluid is your drill bits friend. Slow and steady wins the race.

With that done it was time to bolt the weldments into the fuselage for the last time! A joyful moment tonight while dripping in sweat.

This weekend the workbench goes bye bye to the hanger. I'm out of space in my 1-bay of the garage where I work. Up next is fitting and aligning the axles...and soon the plane will be on its own landing gear!

With that done it was time to bolt the weldments into the fuselage for the last time! A joyful moment tonight while dripping in sweat.

This weekend the workbench goes bye bye to the hanger. I'm out of space in my 1-bay of the garage where I work. Up next is fitting and aligning the axles...and soon the plane will be on its own landing gear!

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Scott's Sonex #1629 - Progress

Congrats Scott! My project stalled out for the summer a couple months back (I'll be hitting it again once the weather cools) and it was my frustration with drilling the titanium that finally caused me to decide to take a break. glad you made it over that hump!

Ryan Roth

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

N197RR - Waiex #197 (Turbo Aerovee Taildragger)

Knoxville, TN (Hangar at KRKW)

My project blog: http://www.rynoth.com/wordpress/waiex/

Time-lapse video of my build: https://www.youtube.com/watch?v=Q8QTd2HoyAM

-

Rynoth - Posts: 1308

- Joined: Fri Jul 26, 2013 1:32 pm

- Location: Knoxville, TN

Re: Scott's Sonex #1629 - Progress

Very cool!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5486

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Scott's Sonex #1629 - Progress

Not quite "on the gear in a year" as Bryan was shooting for, but the gear is on the plan in one year! Friday night and Saturday morning was spent rearranging the garage again to remove the workbench. It's now residing at the back of Steve Stahl's hanger (Waiex #054), which I will be sharing a hanger with when ready.

The titanium main gear legs were test fitted in through the belly skin (fits really good), and the retained with a 1/4" bolt for fitting the axles. Read through the plans last night for the procedure on aligning the axles, and figured it was straight forward enough, and tackled that today.

Still need to make the final bolt attachment of the axle to the TI gear leg, but it's all drilled to 1/4" size now. The wheels and tires with brake drums are assembled, but still need to go through the steps of drilling, taping and bolting on the drum shoes to the axle, etc. It's exciting to be this close to setting it down on the landing gear and wheels!

The titanium main gear legs were test fitted in through the belly skin (fits really good), and the retained with a 1/4" bolt for fitting the axles. Read through the plans last night for the procedure on aligning the axles, and figured it was straight forward enough, and tackled that today.

Still need to make the final bolt attachment of the axle to the TI gear leg, but it's all drilled to 1/4" size now. The wheels and tires with brake drums are assembled, but still need to go through the steps of drilling, taping and bolting on the drum shoes to the axle, etc. It's exciting to be this close to setting it down on the landing gear and wheels!

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Scott's Sonex #1629 - Progress

Scott, it seems you have riveted your firewall on without fitting any of the stuff that goes on it. Also I don't see rudder pedals or cables. Do you have a plan for all that goes in that area. ( just wondering as I have always found it to be so much easier with no firewall in the way ) Keep up the good work

, it is so worth it Chuck, 591pc

, it is so worth it Chuck, 591pc

- chuckster

- Posts: 21

- Joined: Fri Mar 28, 2014 12:46 am

- Location: ramona, ca.

Re: Scott's Sonex #1629 - Progress

I don't want to speak for Scott but I believe his plan is to leave the fuel tank, glareshield, and windscreen off for ease of access while installing rudder pedals, firewall accessories, etc. I believe Scott is even planning on having the panel in position and wired before final assembly of the glareshield for ease of access.

For what it's worth, that's what I did and I had no issues. Great thought though Chuck...you can never have too much access!!

For what it's worth, that's what I did and I had no issues. Great thought though Chuck...you can never have too much access!!

Mike Farley

Waiex #0056 - N569KM (sold)

Onex #245

Waiex #0056 - N569KM (sold)

Onex #245

- MichaelFarley56

- Posts: 1485

- Joined: Thu Jun 02, 2011 11:38 pm

- Location: Columbus, Ohio

Re: Scott's Sonex #1629 - Progress

Yes sir! Mike has my back, and is correct. Right now the glareshield and instrument panel are still cleco'd in place. I'm a tall guy so reaching in from over the top of the upper longerons are workable (for me).

Once I get the silly hole drilled for the cotter pins in the axle, I can mount the axles and brakes and snug up the castle nut an drop the fuselage down on the gear.

My hole keeps getting stuck at the factory drilled hole in the middle of the axle. Sonex ran these holes down pretty deep in the axle (not sure why) - my understanding is this gets tapped to a 10-32 for the wheel pant to screw into the center hole. I'm at least an 1" away from the edge of the axle, and my pilot,hole has bottomed out twice and the tip broke off as I hit the center hole.

Any tips? Or just another couple of 1/8" cobalt drill bits?

Once I get the silly hole drilled for the cotter pins in the axle, I can mount the axles and brakes and snug up the castle nut an drop the fuselage down on the gear.

My hole keeps getting stuck at the factory drilled hole in the middle of the axle. Sonex ran these holes down pretty deep in the axle (not sure why) - my understanding is this gets tapped to a 10-32 for the wheel pant to screw into the center hole. I'm at least an 1" away from the edge of the axle, and my pilot,hole has bottomed out twice and the tip broke off as I hit the center hole.

Any tips? Or just another couple of 1/8" cobalt drill bits?

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Scott's Sonex #1629 - Progress

Scott,

Looks great with the gear hanging down. Regarding the hole that is getting you, could you plug it with a piece of aluminum or steel rod until you get a pilot hole drilled?

Looks great with the gear hanging down. Regarding the hole that is getting you, could you plug it with a piece of aluminum or steel rod until you get a pilot hole drilled?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5486

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Who is online

Users browsing this forum: No registered users and 1 guest