random user submitted photo

Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

Bryan,

I can definitely see that 0.2 degrees difference in the hockey stick bend. Glad your not loosing any sleep over than anymore! :shock:

Get this area buttoned up and start building the foreword fuselage. It will be therapeutic after your recent rebuild.

I can definitely see that 0.2 degrees difference in the hockey stick bend. Glad your not loosing any sleep over than anymore! :shock:

Get this area buttoned up and start building the foreword fuselage. It will be therapeutic after your recent rebuild.

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton Waiex 191 - N191YX

Thanks Scott- getting this buttoned up is the plan.

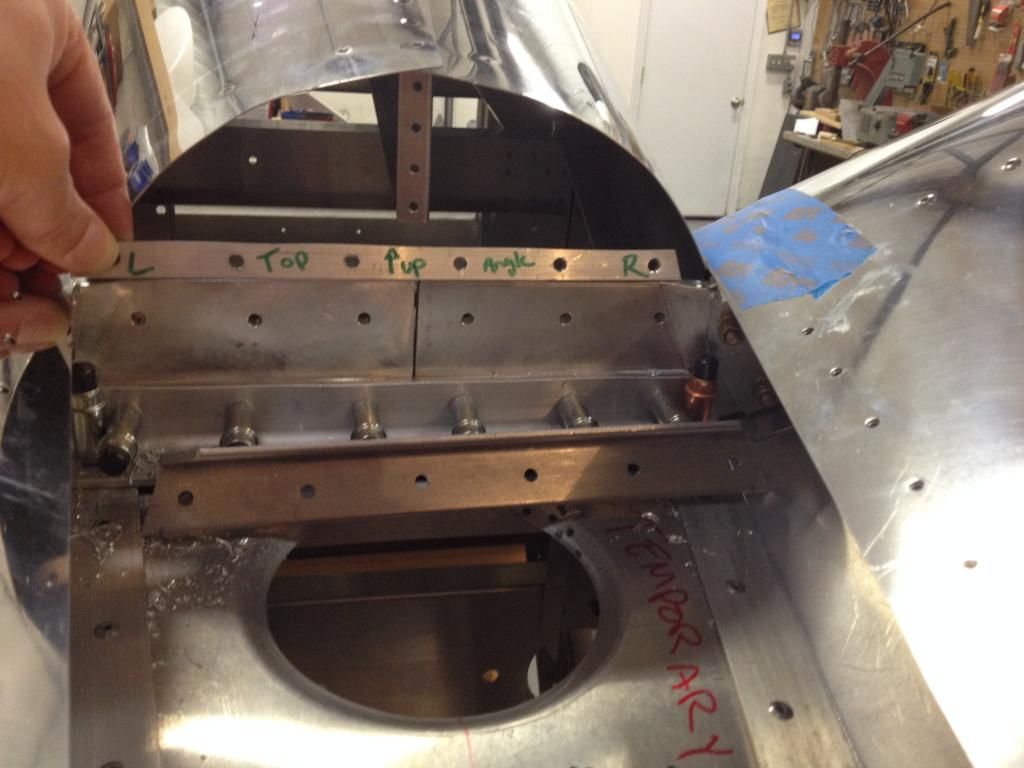

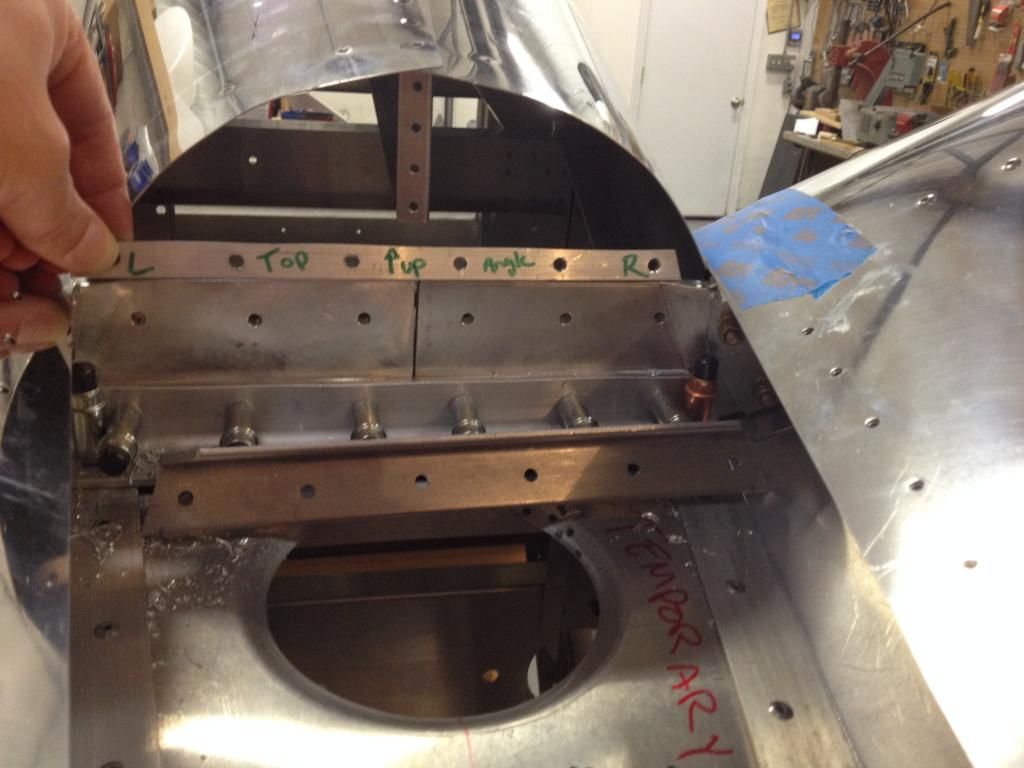

Here is a drill block I made to help transfer holes:

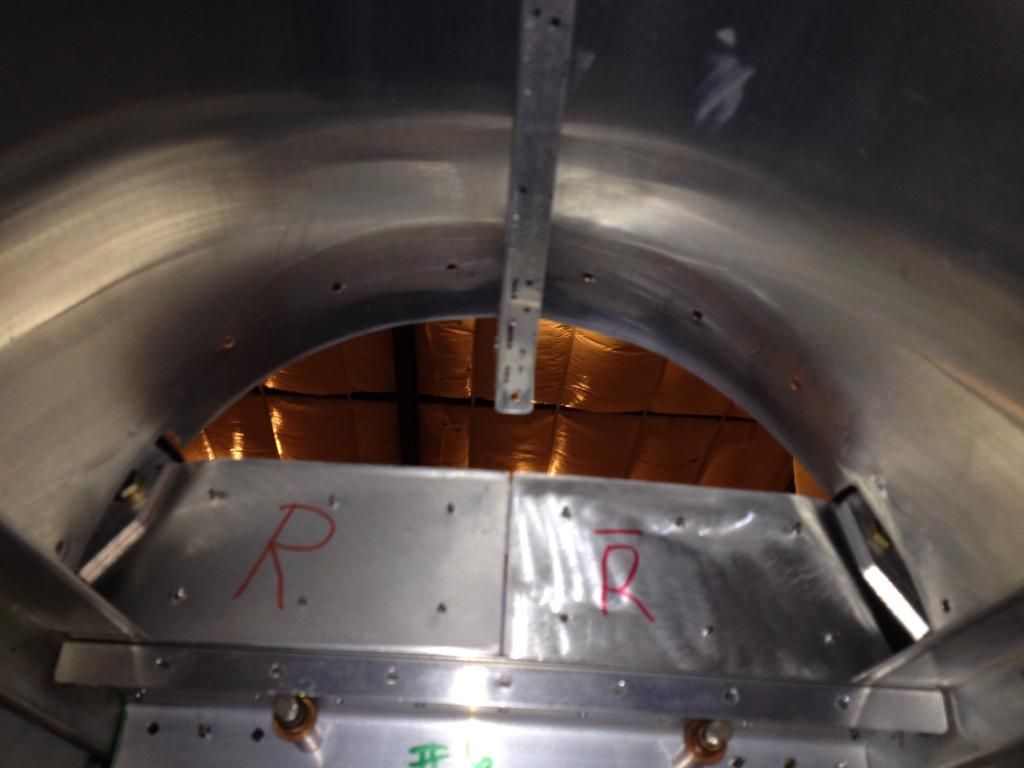

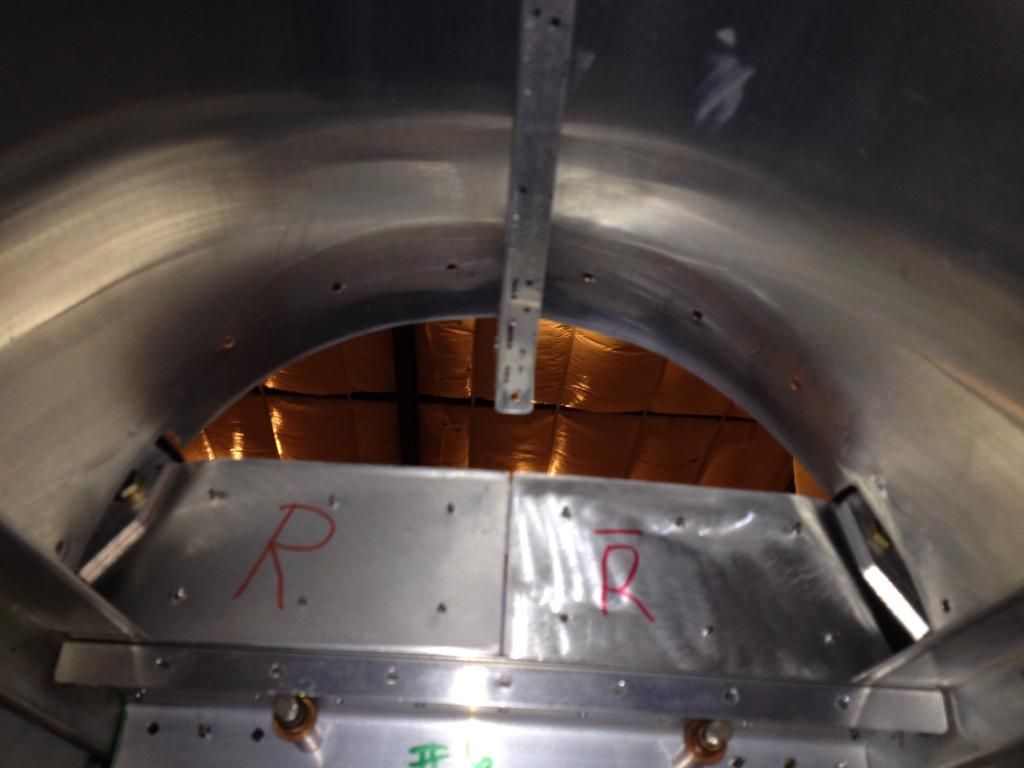

Front side clecoed in:

Back side:

We also did a bunch of countersinking for the aft spar tunnel. Adam's first go with a micro countersink.

Here is a drill block I made to help transfer holes:

Front side clecoed in:

Back side:

We also did a bunch of countersinking for the aft spar tunnel. Adam's first go with a micro countersink.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Adam has destroyed his first countersink. He has a talent there I think. I neglected to get a picture. Two more 120's on order.

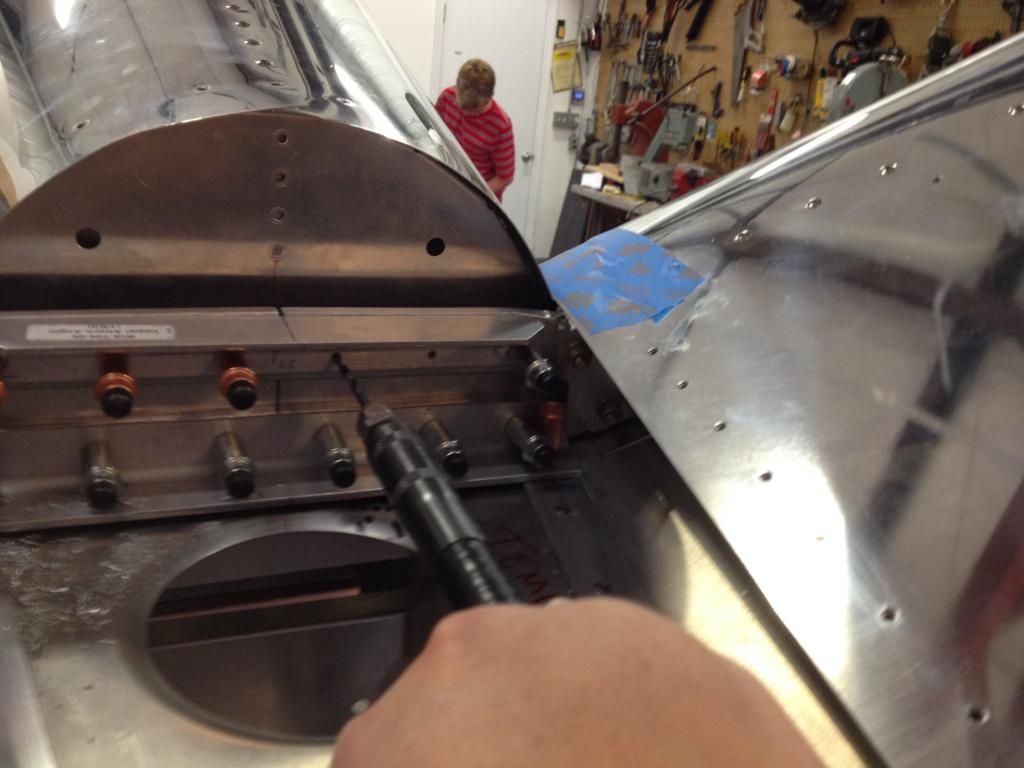

Here is my technique to not screw up the hockey stick again. Thought I would share it. I took a piece of 1/8" scrap and transferred the holes from the upper angle. You can see the scrap clecoed on:

To upsize to the next hole, I use the drill press to put a straight hole through the scrap and the angle:

I am only doing two holes at a time, one per hockey stick. Now the whole thing is clecoed in. I have 1/4" that I can insert the snake drill into before I drill anything. This ensures the bit is straight. Also if the hole gets screwed up, it is usually on the entry and that part is scrap:

I plan to do this with the 7/8" square angle reinforcements too. Instead of using scrap the pilot drilled blocks will get the drill going straight. Between that, the angle, and the shim it is 1.125" of depth that will be done on the drill press

Here is my technique to not screw up the hockey stick again. Thought I would share it. I took a piece of 1/8" scrap and transferred the holes from the upper angle. You can see the scrap clecoed on:

To upsize to the next hole, I use the drill press to put a straight hole through the scrap and the angle:

I am only doing two holes at a time, one per hockey stick. Now the whole thing is clecoed in. I have 1/4" that I can insert the snake drill into before I drill anything. This ensures the bit is straight. Also if the hole gets screwed up, it is usually on the entry and that part is scrap:

I plan to do this with the 7/8" square angle reinforcements too. Instead of using scrap the pilot drilled blocks will get the drill going straight. Between that, the angle, and the shim it is 1.125" of depth that will be done on the drill press

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

I am declaring victory on the top row of bolts:

I bought new material to remake the reinforcements. Too bad I bought 3/4" square instead of 7/8" square. Did I say that already? I forget. The 7/8" is in the way.

I bought new material to remake the reinforcements. Too bad I bought 3/4" square instead of 7/8" square. Did I say that already? I forget. The 7/8" is in the way.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

I am remaking the reinforcement blocks. Pictured is my portable handheld milling machine I used to radius the edge. Makes a heck of a mess.

Dimpled and countersunk aft spar tunnel pieces.

Dimpled and countersunk aft spar tunnel pieces.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Nice work. I should have gotten a micro stop attachment. I love the use of non metal working tools for aluminum! I curious to see how you tackle the TI work!

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton Waiex 191 - N191YX

6061-T6 is the pine of metals.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

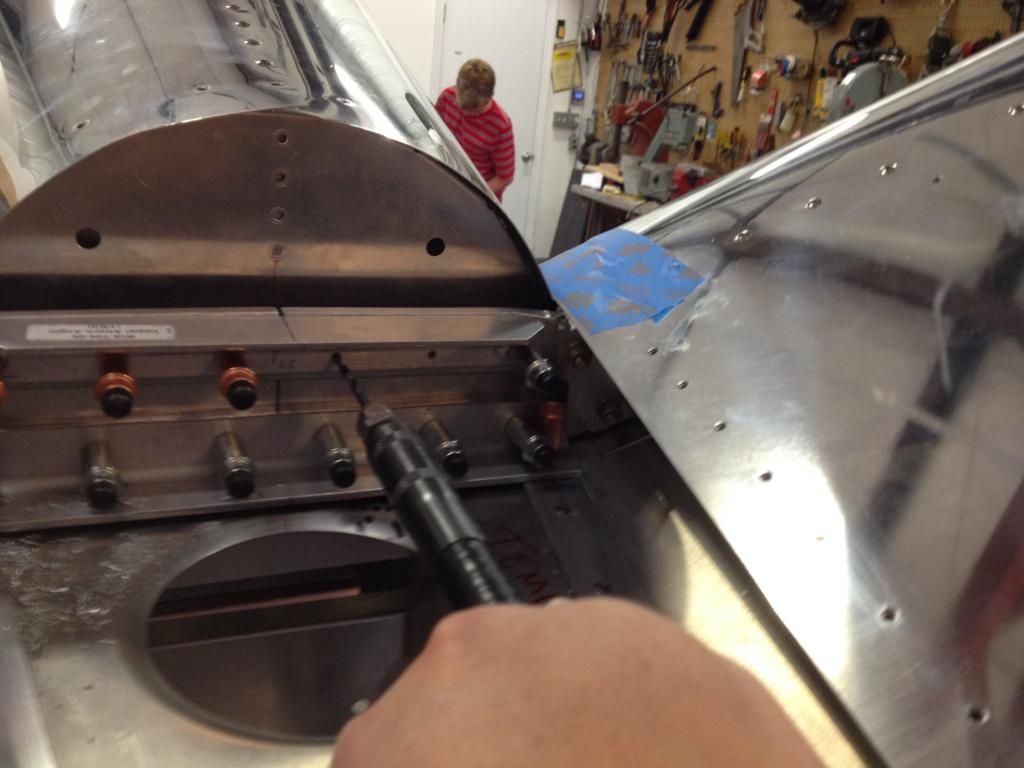

Here is my setup for drilling in those blocks. The inside holes have been brought up to #30 in the blocks, angle, and shim. Only the hockey stick to go. The hockey stick has a #40 right now. Because of the thickness of the stackup, clecos are no good. I have drill bits holding alignment and C clamps to clamp it. Since I took this picture I brought those holes up to #30 in the hockey stick and it came out well.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

This picture is mostly the same as the prior one - except all the holes have been taken up to 3/16". I am officially recovered. Yay! You might notice one difference - I am using AN3 bolts rather than drill bits to hold the horizontal holes in the block aligned. I cut the threads off with a dremel, put some taper on the tip, then chocked up the bolt in the drill press to polish off the cad plate with scotch brite. Makes the fit a little looser, maybe by a couple thou, so as not to beat up the holes.

I have some clever ideas how to drill the last two 1/4" vertical holes that are used to bolt the tail down. You straight tailed heathens may not be interested but the fork tail devils among you may be. Stay tuned.

I have some clever ideas how to drill the last two 1/4" vertical holes that are used to bolt the tail down. You straight tailed heathens may not be interested but the fork tail devils among you may be. Stay tuned.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5496

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Who is online

Users browsing this forum: Google [Bot] and 2 guests