Hot Air

Posted:

Fri Sep 20, 2024 7:09 pmby Skippydiesel

My Legacy/Rotax 912ULS, fitted with custom/home made cowling, has a hot air in the vicinity of the carburettor air inlets.

The under cowl temperature, 50 mm in from the top of the firewall, is roughly 20 degrees centigrade above ambient. I would like it to be no more than + 10C or lower.

I am considering two small (70x70mm?) exit air vents Located;

near the rear edge of the top cowling, above each carburettor

on each side of the lower cowling near the rear edge, a bit below each carburettor

The idea is to encourage greater air movement in the vicinity of the carbs, in the hope that cooler air from the front of cowling inlets, will get to the back of engine bay quicker, with less temperature rise.

Any thoughts / ideas would be most welcome.

Re: Hot Air

Posted:

Fri Sep 20, 2024 7:22 pmby Bryan Cotton

Borrow some ideas from us AeroVee guys

viewtopic.php?f=7&t=4465

Re: Hot Air

Posted:

Sat Sep 21, 2024 7:25 pmby Skippydiesel

Very nice Bryan - thanks.

If possible I would like to avoid significant modification to the cowling (not fond of composite work).

Seems to me that to have such high temperatures near the upper firewall, the air in this area may be trapped & likly under relativly high pressure. If I cut a couple of holes to allow the air to escape, (better) flow will result and the air likly be cooler.

If a couple of strategically placed air outlets will acheive cooler air in the vicinity of the carburettors , this would be my preferred option SUBJECT to no/minimal negative impact (KISS).

Where would you place the holes -

Rear of upper cowling ?

Rear of lower cowling near cowling upper/lower join?

Speculating;

Upper cowling -

Exit into moderately high pressure. Exit air flow may be compromised (by how much?)

Hot/warm air & any fumes will not enter cockpit.

On shutdown, hot air has a good escape route, speeding cooling and reducing incidence of fuel vaporisation.

Oil "spatter/fumes (if any) may collect on windscreen.

Lower cowling sides -

Exit into low pressure area. May increase exit air flow (more efficient?).

Cockpit fresh air vents will be downstream of cowling exit air. Warm, possibly CO contaminated air, entering cockpit.

On shutdown, vents not best placed for hot air to exit (some benefit).

General-

The introduction of an alternative air exit, may impact negatively on existing cooling air flow, through coolant radiator (unlikly) oil cooler (more likly).

Additional vents will have an aesthetic impact on existing very "clean" cowling.

Re: Hot Air

Posted:

Sun Sep 22, 2024 8:36 amby GordonTurner

Hi Skippy

I think you likely have the top and bottom pressures reversed, ie pressure is low at the top of the cowling and higher at the bottom. Otherwise the airframe would be generating negative lift.

Re: Hot Air

Posted:

Sun Sep 22, 2024 12:13 pmby Kai

Skippydiesel wrote:Where would you place the holes -

Rear of upper cowling ?

Rear of lower cowling near cowling upper/lower join?

Speculating;

Upper cowling -

Exit into moderately high pressure. Exit air flow may be compromised (by how much?)

Hot/warm air & any fumes will not enter cockpit.

On shutdown, hot air has a good escape route, speeding cooling and reducing incidence of fuel vaporisation.

Oil "spatter/fumes (if any) may collect on windscreen.

Lower cowling sides -

Exit into low pressure area. May increase exit air flow (more efficient?).

Cockpit fresh air vents will be downstream of cowling exit air. Warm, possibly CO contaminated air, entering cockpit.

On shutdown, vents not best placed for hot air to exit (some benefit).

General-

The introduction of an alternative air exit, may impact negatively on existing cooling air flow, through coolant radiator (unlikly) oil cooler (more likly).

Additional vents will have an aesthetic impact on existing very "clean" cowling.

During flight the air heat in the cowling should be managable, taken into account the air supply from the cooling air intakes, as well as the suction from the outlets. The fun begins when the engine is stopped after flight. Then you have this nicely cowled monstrous lump of hot metal in there without as much as a trifle cooling, cooking anything you might have of semi conductors present. So the object of the exercise must be to get fresh air in there circulating when the plane is at rest. Cooling air supply is already present- fresh air will enter through the outlet chutes, and it rises when heated (thermosyphon): you need to get rid of this. So as an experiment two groups of ø10mm holes were drilled in the top rear of the cowling in two places, symmetrical along the cowling centre line. See the pic for one group.

Did not notice any cooling difference at all during flight after the mod. However, there was a marked, though not tremendous difference with the hot engine stopped.

Re: Hot Air

Posted:

Sun Sep 22, 2024 6:17 pmby Skippydiesel

GordonTurner wrote:Hi Skippy

I think you likely have the top and bottom pressures reversed, ie pressure is low at the top of the cowling and higher at the bottom. Otherwise the airframe would be generating negative lift.

Upper cowling -

Exit into moderately high pressure. Exit air flow may be compromised (by how much?)Note the word MODERATELY as in not as much as other areas - Prop blast and attack angle of cowling likly to result in higher pressure than sides of cowling - Pressure relativly much higher on lower surfaces.

Re: Hot Air

Posted:

Sun Sep 22, 2024 6:24 pmby Skippydiesel

Hi Kai,

"..........groups of ø10mm holes........" x 9 = 90mm x 2 = 180mm. This is a much bigger total, than the 2x 25 mm holes, I was considering as a start point.

Disappointing that you saw no reduction in, in flight, undercowl temperatures. Why do you think there was no change?

Where in the cowling did you place your thermocouple ?

What are your, in flight, OAT & under cowl temps?

Re: Hot Air

Posted:

Sun Sep 22, 2024 9:39 pmby Kai

Well,

I do not think it was disappointing. What bothered me were the after flight temps.

No idea- could have been that the introduced leak was too small to make a difference?

I used temp strips. One was placed up front under the cowling over the gearbox. The other was sitting on top of the ignition modules. It´s three years ago that I did this, and I did not make a note of temps. Though lower after the holes, the module temps were still too high. I got hold of some aftermarket modules that were positioned on the firewall at the bottom of the cowling, close to the outlet chutes. The modules now never get hotter than luke warm.

OAT during the excuses we have had for summers these past years were 10-20C.

Re: Hot Air

Posted:

Mon Sep 23, 2024 1:16 pmby builderflyer

[quote

During flight the air heat in the cowling should be managable, taken into account the air supply from the cooling air intakes, as well as the suction from the outlets. The fun begins when the engine is stopped after flight. Then you have this nicely cowled monstrous lump of hot metal in there without as much as a trifle cooling, cooking anything you might have of semi conductors present. So the object of the exercise must be to get fresh air in there circulating when the plane is at rest. Cooling air supply is already present- fresh air will enter through the outlet chutes, and it rises when heated (thermosyphon): you need to get rid of this. So as an experiment two groups of ø10mm holes were drilled in the top rear of the cowling in two places, symmetrical along the cowling centre line. See the pic for one group.

Did not notice any cooling difference at all during flight after the mod. However, there was a marked, though not tremendous difference with the hot engine stopped.[/quote]

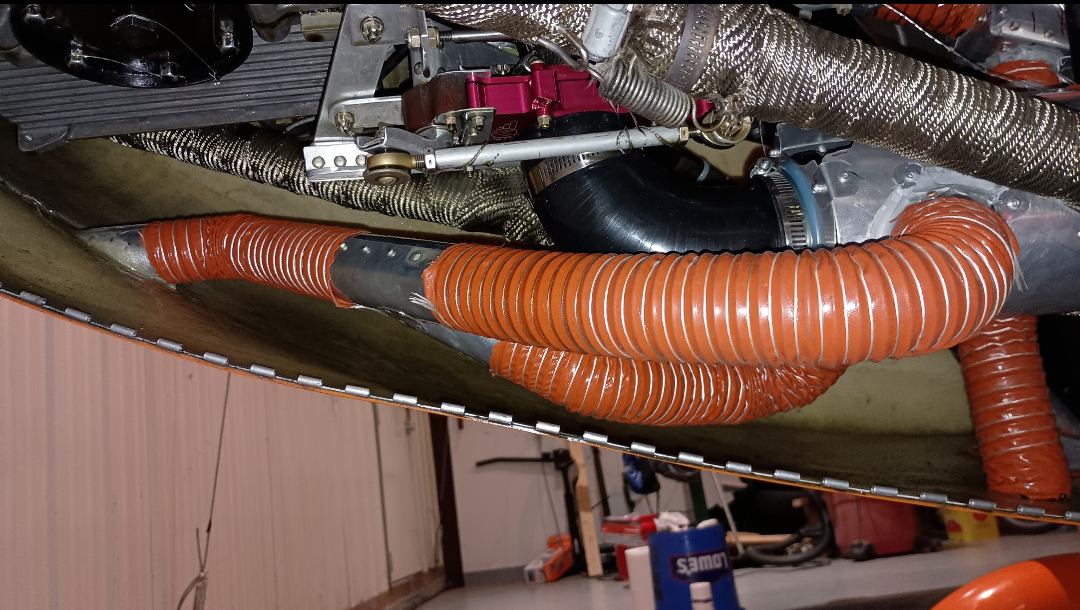

Just to back up what Kai said here........I finally (after 19 years) got tired of burning out ignition coils on the back of my Jabiru 3300 after shutdown. So I recently added two 2" (50mm) diameter vents above the coils, as seen in the attached photo, to let heat escape after shutdown. During flight there is no noticeable difference in temps at the back of the engine but only time will tell if the coils stop burning out after a flight. My disappointment so far is the small amount of heat I feel exiting the vent holes after shutdown..........expected more.

Art,,,,,,,,,,,,,.Sonex taildragger #95,,,,,,,,,,,,,,,,,Jabiru 3300 #261

Re: Hot Air

Posted:

Mon Sep 23, 2024 2:46 pmby AlexZ

Kai wrote:The fun begins when the engine is stopped after flight. Then you have this nicely cowled monstrous lump of hot metal in there without as much as a trifle cooling, cooking anything you might have of semi conductors present. So the object of the exercise must be to get fresh air in there circulating when the plane is at rest. Cooling air supply is already present- fresh air will enter through the outlet chutes, and it rises when heated (thermosyphon): you need to get rid of this. So as an experiment two groups of ø10mm holes were drilled in the top rear of the cowling in two places, symmetrical along the cowling centre line. See the pic for one group.

Maybe this is an idea. A little hinged flap on top with weight that will open it at low speed.

https://youtu.be/rM0AE6a9H2U?si=MXAnlppAS9nV-qTF