Page 1 of 1

Fairlead Mount Blocks

Posted:

Wed Apr 10, 2024 8:28 pmby BobDz

I've been experimenting...

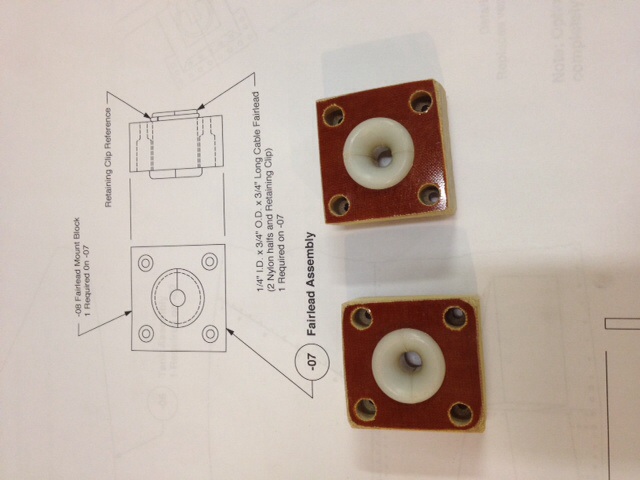

Got tired of waiting for parts so I ordered 3/4" phenolic on my own. HDPE came up as an alternative. For fun, I ordered a piece of that as well.

The mounting block is a pretty "inert" piece. In a simpler world it would probably be a block of wood. Not much force or stress applied to this piece. It's sole purpose is to provide a stable hole for the nylon cable fairleads. Pretty simple.

So I made both. Here are the results of my "experiment ".

HDPE is much lighter in weight.

HDPE is quite a bit cheaper.

HDPE machines VERY easily.

Phenolic is a bit more difficult to machine.

Can't think of a reason not to use HDPE.

Re: Fairlead Mount Blocks

Posted:

Wed Apr 10, 2024 10:46 pmby Bryan Cotton

I was going to say wear, but then I remembered the nylon insert.

How much weight does it save?

Re: Fairlead Mount Blocks

Posted:

Sat Apr 13, 2024 12:00 pmby BobDz

Bryan

1.1 ounce each

Re: Fairlead Mount Blocks

Posted:

Sat Apr 13, 2024 12:43 pmby Area 51%

That must be extremely light stuff you're working with. Each of my blocks is just barely over an ounce to start with.

Re: Fairlead Mount Blocks

Posted:

Sat Apr 13, 2024 4:06 pmby peter anson

When I built my Sonex I made nearly all the phenolic parts from nylon; fairleads, rudder pedal bearings and flap tube bearings. On the bearing blocks I added an aluminium plate to spread the bolt load which I don't think was called in the original drawings. I wasn't trying to experiment; it was just a matter of using material that was available. In fact the only place I used phenolic material was for the the canopy latch striker plates because I happened to have some 1/4" sheet. After 12 years and 500 hours all the nylon parts are still working fine and have presented no problems.

Peter

Re: Fairlead Mount Blocks

Posted:

Sat Apr 13, 2024 5:32 pmby BobDz

Area 51% wrote:That must be extremely light stuff you're working with. Each of my blocks is just barely over an ounce to start with.

I have to say that I wasn't impressed with the phenolic I received. It was heavy, and very hard to drill. Not like any phenolic I had used before.

Re: Fairlead Mount Blocks

Posted:

Sat Apr 13, 2024 5:39 pmby BobDz

Peter

I'm actually wondering why Derlin is called out in the plans for thr Flap Tube mounting blocks. Derlin is typically used for machined parts like gears and splined shafts - things that require high strength. I would have thought UHMW plastic would have been used. In the woodworking world UHMW is called "slippery plastic". It's a great bearing material, especially in a situation like the Flap Tube which isn't high stress, or high use.

I'm pretty sure I'm using UHMW.