random user submitted photo

Auto Pilot in a Onex

12 posts

• Page 1 of 2 • 1, 2

Auto Pilot in a Onex

Where is everyone installing pitch and roll servos in the Onex?

CFI, CFI—I, MEI, MEI-I, ATP, A&P

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

- N21X

- Posts: 61

- Joined: Mon Aug 27, 2018 5:29 pm

Re: Auto Pilot in a Onex

N21X wrote:Where is everyone installing pitch and roll servos in the Onex?

I installed both about a year ago. The roll servo is installed on the right side (pilot's perspective) of the floor just forward of the main spar. (It could have been installed on the left side.) In that position it is out of the way and almost impossible to step on it or kick it.

The pitch servo is installed on the right side of the floor (pilot's perspective) just aft of the rear spar carry thru.

Here is an email I sent to another OneX builder who asked a similar question.

I took some photos of my roll servo installation. I couldn’t get great shots because it was difficult to place and point the camera in such a tight space.

https://jasflyer.com/cabinheat/Bell%20Crank.jpg The silver oblong piece in the middle of the picture is a bell crank I fabricated from 1/8" thick aluminum. It is designed to be connected to ONX-C03-10. When I made this piece I didn’t know how far below the pivot point the servo push rod would need to be connected. As you can see I drilled 4 holes. I ended up using the top one. The lower holes resulted in over control by the servo. So the lesson I learned that I can pass on to you is: your bell crank will only need to extend about 3 inches below the bottom of ONX-C03-10. I suggest you drill more than one hole, then experiment to find the one that gives you the correct servo/control response.

https://jasflyer.com/cabinheat/Roll%20Servo.jpg It was very difficult to get a good picture of this because the control stick frame (ONX-C03-03) blocked the view. (In practice this is a good thing, because the control stick frame also covers and protects the servo from being stepped on!) You’ll want to place the servo as far right as possible. This provides the best geometry for the servo push rod. Also place it as far back as possible. Keep in mind where the electrical connector is. I had a devil of a time screwing mine in because it is so close to the spar.

I custom designed and fabricated the servo mount tray. It has three sides and no bottom. The servo connects to the front of the tray using the mounting hardware that came with the MGL servo. At the bottom of the three sides are ‘feet’ bent away at a 90 degree angle, which are then riveted to the fuselage floor.

I’d estimate it took me about 1 hour to fabricate the bell crank, 2 hours to fabricate the tray and another 2 hours to install the whole mess in the plane.

Let me know if you have any questions. Good luck.

-- Michael

OneX N169XE

author of the 'Flight Data Viewer'

OneX N169XE

author of the 'Flight Data Viewer'

- XenosN42

- Posts: 421

- Joined: Thu Jul 24, 2014 4:45 pm

- Location: PA, USA

Re: Auto Pilot in a Onex

Merle located the roll servo in the right stub wing on N362DV. I don't have pitch in it, but would recommend it if your going to fly any distance.

Vince Homer

Vince Homer

- vhhomer

- Posts: 37

- Joined: Mon Dec 10, 2012 1:48 am

Re: Auto Pilot in a Onex

Michael,

Thank you for the great info!

Thank you for the great info!

CFI, CFI—I, MEI, MEI-I, ATP, A&P

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

- N21X

- Posts: 61

- Joined: Mon Aug 27, 2018 5:29 pm

Re: Auto Pilot in a Onex

Could you send me some pics/details of the pitch servo you installed aswell? Have you flown the autopilot?

CFI, CFI—I, MEI, MEI-I, ATP, A&P

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

- N21X

- Posts: 61

- Joined: Mon Aug 27, 2018 5:29 pm

Re: Auto Pilot in a Onex

N21X wrote:Could you send me some pics/details of the pitch servo you installed aswell? Have you flown the autopilot?

Hi,

I'll take a few pictures of the pitch servo installation when I go to the airport later on this week. Should be before Friday.

I installed the servos in N169XE last October and I've flown using it often. On a recent flight I just want to go up to relax and enjoy a cool, 100% clear day. The flight was about an hour and I had the auto pilot on about 95% of the time. That included much of the climb, and about half of the descent.

I have an MGL Discovery iEFIS. Once I figured out the correct configuration parameters the servos worked very well. If you have that combination AND install the servos as I did let me know and I'll send you the parameters, so that you can use them as a starting point.

-- Michael

OneX N169XE

author of the 'Flight Data Viewer'

OneX N169XE

author of the 'Flight Data Viewer'

- XenosN42

- Posts: 421

- Joined: Thu Jul 24, 2014 4:45 pm

- Location: PA, USA

Re: Auto Pilot in a Onex

Here is how I attached a Garmin servo to the elevator idler arm in my Onex that I am still building.

Thanks,

Jim Stroud

Thanks,

Jim Stroud

- Attachments

-

archive (14).zip

archive (14).zip- (240.46 KiB) Downloaded 373 times

- stroudj002

- Posts: 15

- Joined: Wed Dec 05, 2018 6:45 pm

Re: Auto Pilot in a Onex

N21X wrote:Could you send me some pics/details of the pitch servo you installed as well? Have you flown the autopilot?

Hi,

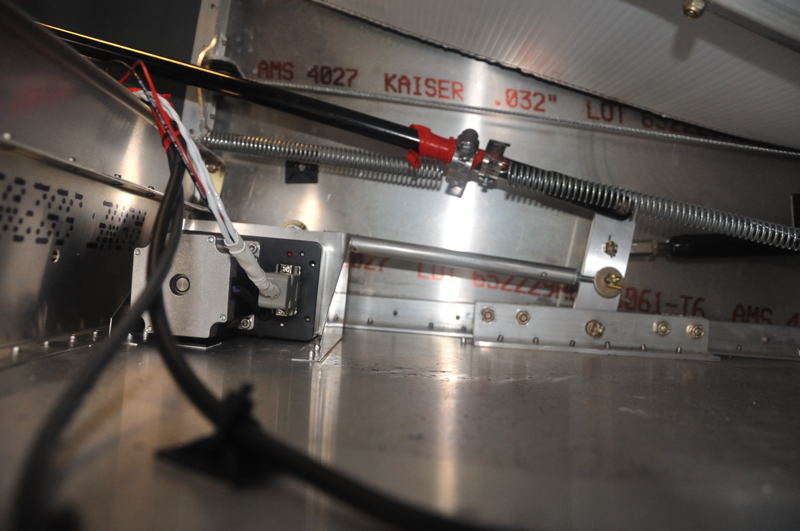

Here is a picture of the pitch servo installation. The servo is located just aft of the rear spar carry thru. This picture shows more detail about the mounting tray I fabricated. The roll servo uses the same tray.

-- Michael

OneX N169XE

author of the 'Flight Data Viewer'

OneX N169XE

author of the 'Flight Data Viewer'

- XenosN42

- Posts: 421

- Joined: Thu Jul 24, 2014 4:45 pm

- Location: PA, USA

Re: Auto Pilot in a Onex

So I installed the pitch just forward of the idler, all good, just need to connect and ensure the arm doesn't overtravel.

I installed the roll servo forward of spar all the way to the right. Connecting to the control stick it seems that a problem would exist because the roll has both pitch and roll connected to the rod arm. Has anyone flown this setup and are there any issues?

I installed the roll servo forward of spar all the way to the right. Connecting to the control stick it seems that a problem would exist because the roll has both pitch and roll connected to the rod arm. Has anyone flown this setup and are there any issues?

CFI, CFI—I, MEI, MEI-I, ATP, A&P

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

US ARMY Veteran

Rv9a - Flying

Rv3a - Flying

Onex #165 (Flush riveted w/AM 13 AEROMOMENTUM 127hp & a 59” 4 blade prop)

- N21X

- Posts: 61

- Joined: Mon Aug 27, 2018 5:29 pm

12 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 14 guests