95.1 Degrees….

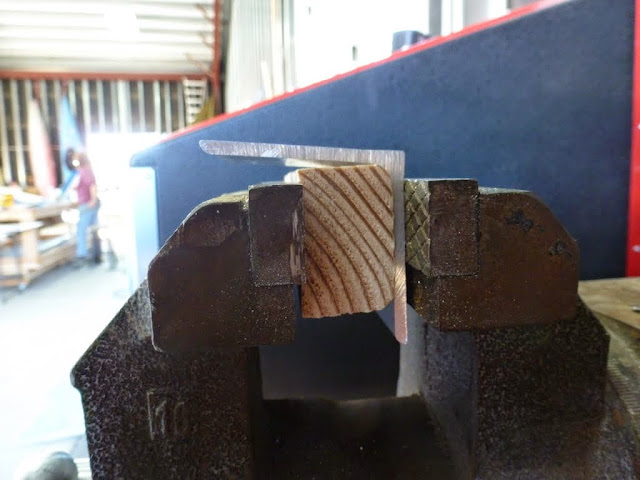

So there’s this bracket you need to make in the stabilizer skeleton to hold the aft root rib to the forward spar. You have to open up a 2”x2” angle from 90 degrees to 95.1 degrees. Aside from not knowing how to measure that 0.1 degree, the bending was made easier with a claw hammer and my big Chinese vise:

Careful measurement showed that I got it to 95.5 – but a quick rap with the hammer drove it back down to where it needed to be:

A quick pass on the belt sander took the little bit of curve out of the outside flats, and it matched the drawing – as close as I could tell.

Making all these brackets and clips is kind of fun!

Paul

Careful measurement showed that I got it to 95.5 – but a quick rap with the hammer drove it back down to where it needed to be:

A quick pass on the belt sander took the little bit of curve out of the outside flats, and it matched the drawing – as close as I could tell.

Making all these brackets and clips is kind of fun!

Paul