random user submitted photo

Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

It seems you can't get the tank out with the angles in. But that is ok.

I did a bunch of little tasks tonight then set up for a leak check:

Filled with H2O, coffee can under the sump:

I put a milk crate on my old arc welder dolly, so I can roll it out of the garage and drain it without any lifting.

I did a bunch of little tasks tonight then set up for a leak check:

Filled with H2O, coffee can under the sump:

I put a milk crate on my old arc welder dolly, so I can roll it out of the garage and drain it without any lifting.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Bryan,

Good job on installing the oops fittings, thanks for all the good pics of the process. I think that is the way to go with the tanks before install into the plane. You are saving yourself a lot of grief later on.

WaiexN143NM

Michael Radtke

Good job on installing the oops fittings, thanks for all the good pics of the process. I think that is the way to go with the tanks before install into the plane. You are saving yourself a lot of grief later on.

WaiexN143NM

Michael Radtke

- WaiexN143NM

- Posts: 1206

- Joined: Mon Sep 15, 2014 1:04 am

- Location: palm springs CA

Re: Cotton Waiex 191 - N191YX

Thanks Michael!

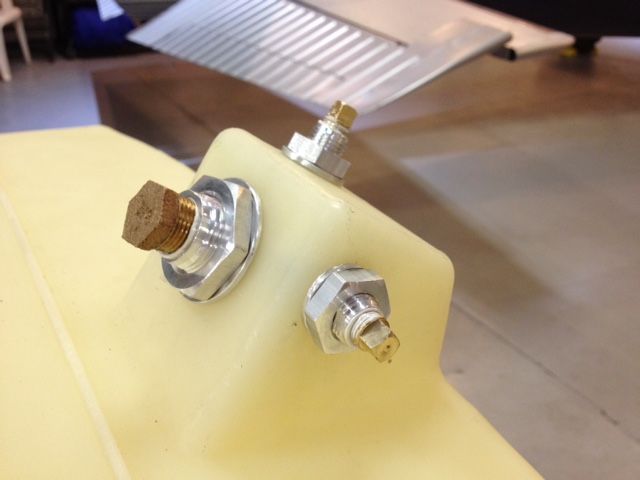

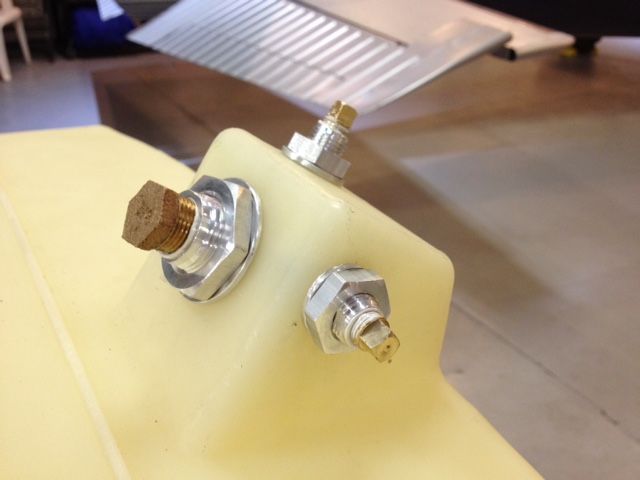

Had a little water in the coffee can. How tight do you sock down the oops fittings? Looks like I need to make two tighter.

Had a little water in the coffee can. How tight do you sock down the oops fittings? Looks like I need to make two tighter.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Hi Bryan!

Let us know if any more drips! Slowly snug up till it stops! Good luck!

WaiexN143NM

Michael Radtke

Let us know if any more drips! Slowly snug up till it stops! Good luck!

WaiexN143NM

Michael Radtke

- WaiexN143NM

- Posts: 1206

- Joined: Mon Sep 15, 2014 1:04 am

- Location: palm springs CA

Re: Cotton Waiex 191 - N191YX

Bryan,

The tool for grinding the inside surface flat should make it square to the hole, but the hole its self might not be square with the outside surface, thus inside and outside surfaces might not be parallel. Back off the nuts and eye-ball the gap between them and the tank's exterior while pulling out on fitting so it sits square inside. If not good, that hard outside washer may have to be replaced with a more compliant material. O-rings work for that, but then really need to undercut the underside of the nuts to make retaining grooves to keep O-rings from squishing out to the side.

David A..

The tool for grinding the inside surface flat should make it square to the hole, but the hole its self might not be square with the outside surface, thus inside and outside surfaces might not be parallel. Back off the nuts and eye-ball the gap between them and the tank's exterior while pulling out on fitting so it sits square inside. If not good, that hard outside washer may have to be replaced with a more compliant material. O-rings work for that, but then really need to undercut the underside of the nuts to make retaining grooves to keep O-rings from squishing out to the side.

David A..

- DCASonex

- Posts: 935

- Joined: Mon Sep 12, 2011 8:04 pm

- Location: Western NY USA

Re: Cotton Waiex 191 - N191YX

David,

I think I ground reasonably perpendicular. I was careful about that.

Here is my leak check setup, rev 2:

I pressurized the tank and put soapy water on the joints. The big fitting was blowing a lot of bubbles. Took me a few iterations of tightening it before they stopped. I was being conservative. I think my O-rings look like a good fit. After I got the bubbles to stop at the fittings, found my next big leak at the balloon. I had mistakenly used a red one that I had used on the C140 leak check back in 2012. I switched to an orange balloon and it was better. Gotta stick to the color scheme. Lesson learned.

I think I ground reasonably perpendicular. I was careful about that.

Here is my leak check setup, rev 2:

I pressurized the tank and put soapy water on the joints. The big fitting was blowing a lot of bubbles. Took me a few iterations of tightening it before they stopped. I was being conservative. I think my O-rings look like a good fit. After I got the bubbles to stop at the fittings, found my next big leak at the balloon. I had mistakenly used a red one that I had used on the C140 leak check back in 2012. I switched to an orange balloon and it was better. Gotta stick to the color scheme. Lesson learned.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Twenty four hours later the balloon was still inflated. I declared victory on the leak check.

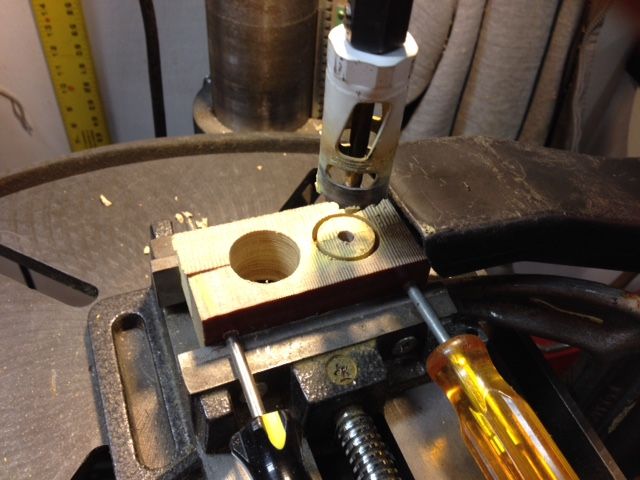

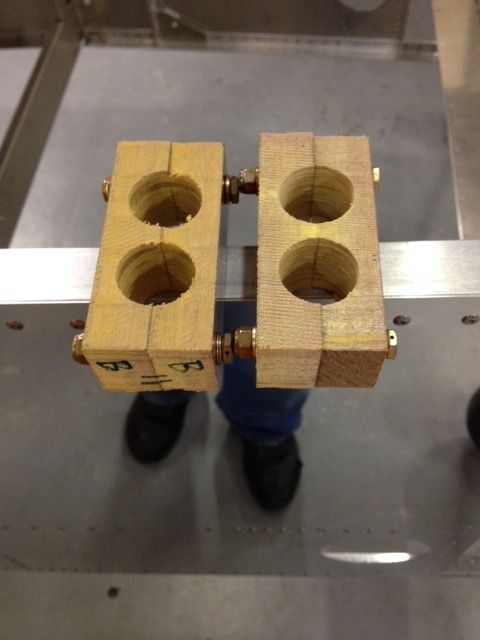

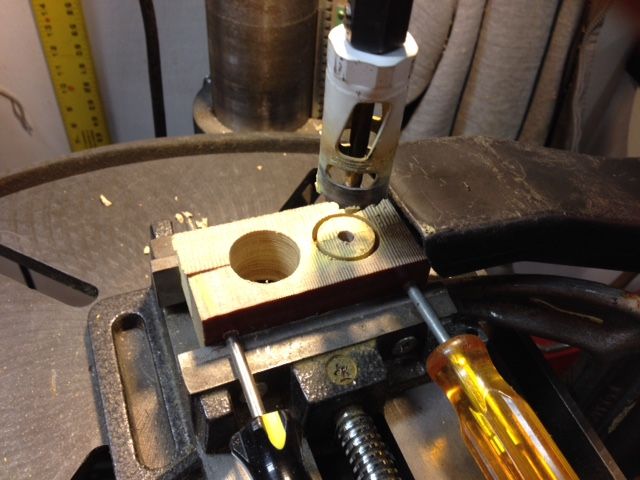

I made rudder pedal blocks tonight. Used my template to transfer holes to phenolic:

Holesaw time:

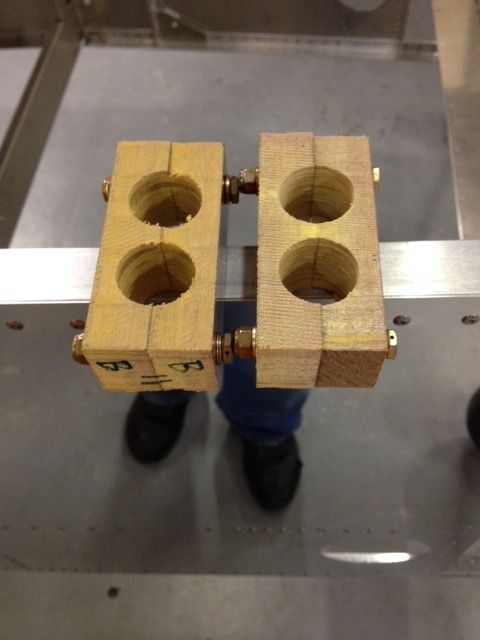

Done except for some belt sander work:

I made rudder pedal blocks tonight. Used my template to transfer holes to phenolic:

Holesaw time:

Done except for some belt sander work:

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Thanks for all your great posts Bryan. Very interesting!

-

kevinh - Posts: 372

- Joined: Mon Feb 23, 2015 10:46 pm

- Location: San Mateo, CA

Re: Cotton Waiex 191 - N191YX

Thanks Kevin! Since you are taking notes for your build, definitely make your phenolic blocks to your parts and not just to the print. I used a transfer punch to transfer holes from my flap bracket to a piece of aluminum scrap. First set we made by measurement and people are just not accurate enough. If you are not going the machined angle kit route, I would make the template to the print and make all the angles and phenolic to the template.

The advantage of the template is you can rivet the angles in and still make phenolic blocks that will bolt up!

The advantage of the template is you can rivet the angles in and still make phenolic blocks that will bolt up!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Spent some sad time in the hangar last Tuesday making progress. Adam was there earlier but I didn't tell him about the accident until today.

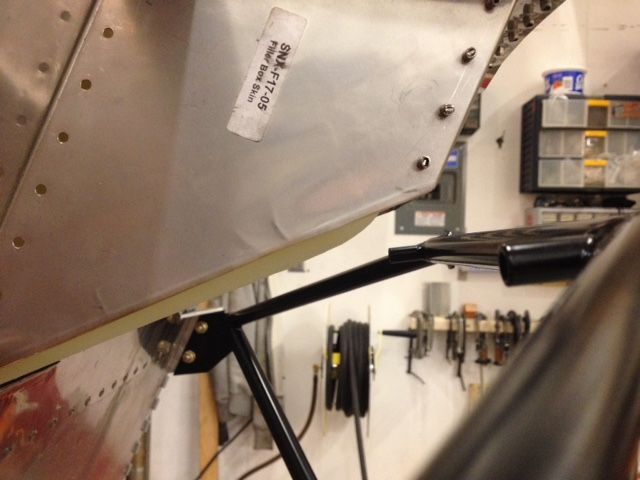

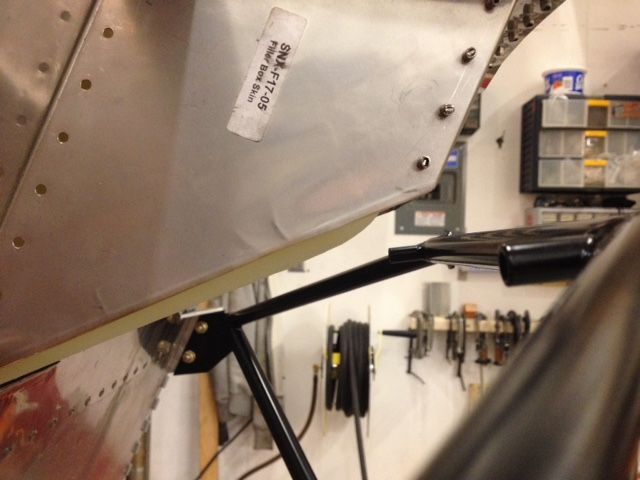

My fuel filler box is too small. So, I decided to cut off the floor and modify it.

Here is the floor cut out.

You can see how much the filler neck would interfere by in this picture:

RIP Jeremey and Mike.

My fuel filler box is too small. So, I decided to cut off the floor and modify it.

Here is the floor cut out.

You can see how much the filler neck would interfere by in this picture:

RIP Jeremey and Mike.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5489

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Who is online

Users browsing this forum: No registered users and 17 guests