Page 46 of 157

Re: Cotton Waiex 191 - N191YX

Posted:

Sun Mar 22, 2015 9:50 pmby Bryan Cotton

Possibly - page C08, center controls. That was the page where you nearly panicked before you realized it didn't apply to you.

Re: Cotton Waiex 191 - N191YX

Posted:

Mon Mar 23, 2015 12:03 pmby Sonex1462

Hi Bryan, For my Sonex it is on SNX-C09. Sonex PN SNX-C06-15. It also says Gardner Spring #36108G or Equal.

Re: Cotton Waiex 191 - N191YX

Posted:

Mon Mar 23, 2015 11:57 pmby Bryan Cotton

Thanks John!

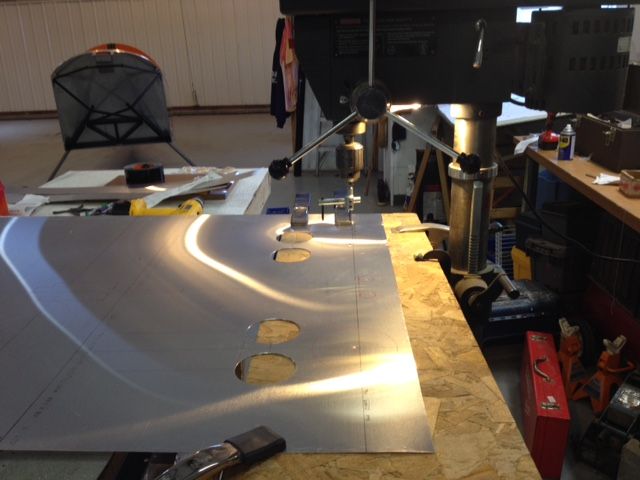

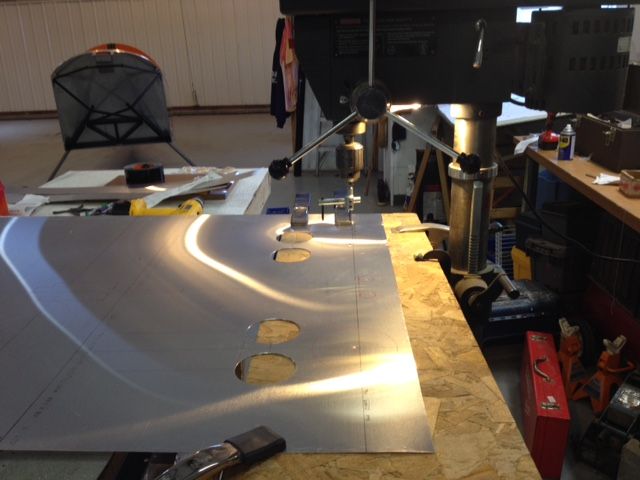

I am working the seat sling. Had to get out the steampunk drill for the holesaw:

Ryan's Waiex blog is super helpful here.

Re: Cotton Waiex 191 - N191YX

Posted:

Tue Mar 24, 2015 11:23 pmby Bryan Cotton

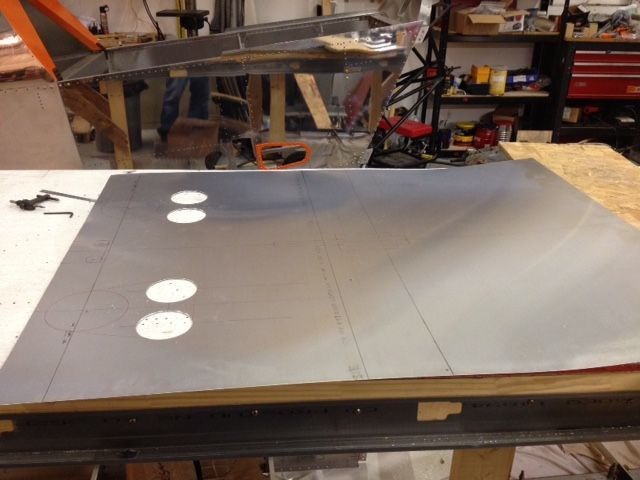

I didn't have a 4.5" holesaw so I elected to use the flycutter. I think next time rather than use a flycutter I will spread peanut butter on the general area and lure a rabid beaver into the hangar to chew through it. I hate fly cutters.

Gave up on the fly cutter and resorted to the nibbler, dremel, and files.

I didn't have any peanut butter and I don't know if they have beavers in Illinois. It came out OK, still have to clean up the rectangular holes some.

If you look closely you can see the reflection of brake-a-saurus in the background.

Re: Cotton Waiex 191 - N191YX

Posted:

Tue Mar 24, 2015 11:29 pmby wlarson861

I had to use a fly cutter for mine but I couldn't get it in the drill press. I had to use a 1/2 inch drill and run at slow speed. NOT recomended!!!! Don't know how I avoided injury! Put it on the floor on plywood and stood on the seat pan while I drilled.

Re: Cotton Waiex 191 - N191YX

Posted:

Wed Mar 25, 2015 1:48 amby ihab

Bryan Cotton wrote:... resorted to the nibbler, dremel, and files.

Sounds frustrating. :P For the straight cuts, you are aware I take it of the Olfa P-800 technique? Clamp a steel straightedge; take several scoring cuts; then snap off the part. If you have a cut that stops inside your part on both ends, then score in both directions, starting at the ends and ending up at the middle, so you don't overrun the cut line.

http://www.zenith.aero/profiles/blogs/2 ... ost:171712Ihab

Re: Cotton Waiex 191 - N191YX

Posted:

Wed Mar 25, 2015 9:16 amby Bryan Cotton

Ihab,

I have heard of the Olfa technique, and I think I did it once with 2023-T3. But you are wrong about it being frustrating. Frustration is when you screw up your hockey sticks or wing rigging. When you have at with files and it comes out good, it is therapy!

Re: Cotton Waiex 191 - N191YX

Posted:

Wed Mar 25, 2015 9:25 amby Gripdana

I'm with Bill. I used the fly cutter in the 1/2 inch drill motor also in the same way. I could not do that at work. If something happened OSHA would have a field day. But that is the beauty of home building. Your seat pan looks great Bryan.

Re: Cotton Waiex 191 - N191YX

Posted:

Wed Mar 25, 2015 2:59 pmby Rynoth

I used the fly cutter in a cordless drill at high speed with the clutch set pretty low, and just let it lightly score the surface... went deeper and deeper over the course of a minute or so, then clean hole. Since the clutch was set low, if the cutter caught it would just stop spinning, no danger twisting/torquing the material.

Cotton Waiex 191 - N191YX

Posted:

Wed Mar 25, 2015 3:10 pmby Sonex1517

I did the same with an air drill dialed way back. Just had to keep reminding myself not to put my hands anywhere near it.

Worked well.