Bryan:

I'll quote my B-I-L:

"That looks great, if you can't make it fly it we can turn it into one heck of a BBQ smoker!"

SonexBuilders.net

A Forum for Sonex Aircraft Builders and Enthusiasts

http://sonexbuilders.net/

Cotton Waiex 191 - N191YX

Page 37 of 157

Re: Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

Scott,

My former co-workers back in Stratford used to tell me I may as well put chains on my hummelbird fuselage and hang it off the swing set. I haven't proved them wrong yet!

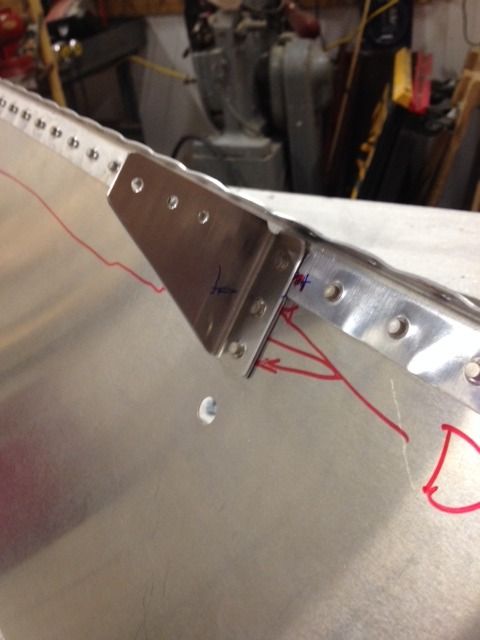

The issue with my new flange is I had to remake this clip and add a shim:

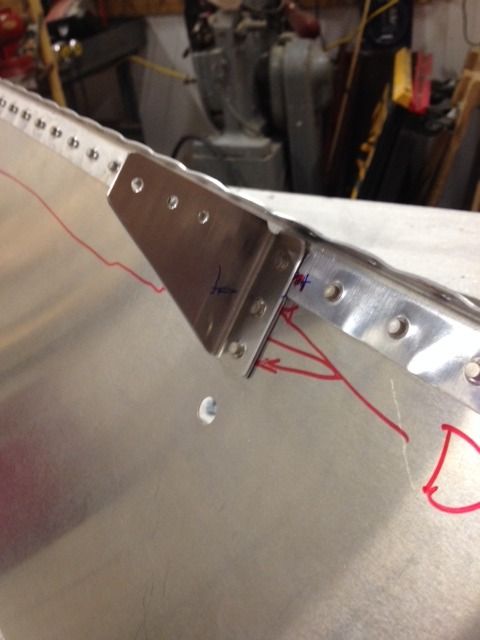

All flush riveted up:

I have the nose torn back off for deburr. Then we can rivet.

My former co-workers back in Stratford used to tell me I may as well put chains on my hummelbird fuselage and hang it off the swing set. I haven't proved them wrong yet!

The issue with my new flange is I had to remake this clip and add a shim:

All flush riveted up:

I have the nose torn back off for deburr. Then we can rivet.

Re: Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

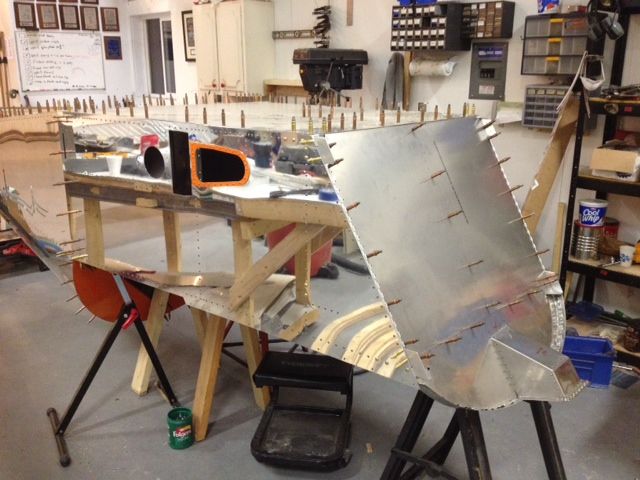

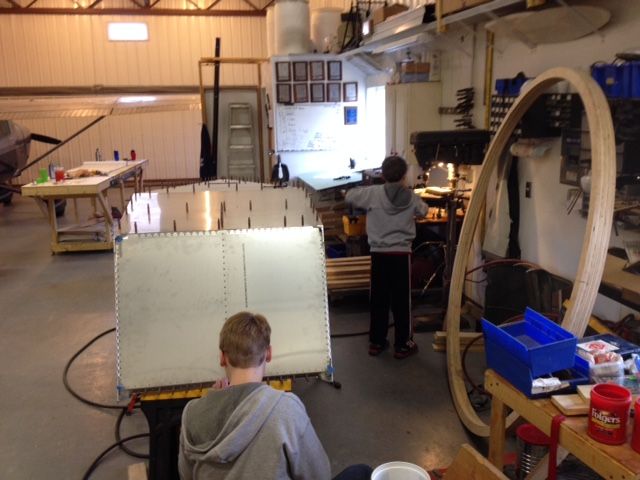

We have the forward frame of the tailcone all deburred, bolted and riveted up.

The tailcone is upside down again waiting for the nose to go back on.

Is this a good time to close out the upper crossmember? Seems like the bottom is off just so we could bolt it up but I could not find a reference on the plans to rivet it.

The tailcone is upside down again waiting for the nose to go back on.

Is this a good time to close out the upper crossmember? Seems like the bottom is off just so we could bolt it up but I could not find a reference on the plans to rivet it.

Re: Cotton Waiex 191 - N191YX

I thought that was called for when finishing the Turtledeck. In any case, you'll be drilling a lot of holes in the cross tie box wheen you install piano hinges for the seat pan, so if it's still not riveted, it'll make deburring those holes easier.

Re: Cotton Waiex 191 - N191YX

One of the things that was done on my cross tie box was to cut a semi circle opening in each end on the bottom cover so as to allow access to the nuts on the inside. During annual it makes checking these for proper torque much easier.

Be nice if I had a photo ...

Dale

N319WF

Be nice if I had a photo ...

Dale

N319WF

Re: Cotton Waiex 191 - N191YX

Here is another tool idea. There were some tight spots where I could not countersink the holes in the forward wing attach. I had this coupler and modified it by running the ID up to 1/4". Hacked the head off an AN4 bolt for one side and the microstop went into the other side.

In hindsight my angle sander would have worked too. It takes a 1/4" arbor.

In hindsight my angle sander would have worked too. It takes a 1/4" arbor.

Re: Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

I started working the motor mount. It is tight to get the lower motor mount between the angles, but once you get it in it is loose.

I have the fuselage all level again. I think I will put some angles on the floor, the 4 and something inch distance as specified, then use plumb bobs. It will make more sense when I have pictures to post.

I have the fuselage all level again. I think I will put some angles on the floor, the 4 and something inch distance as specified, then use plumb bobs. It will make more sense when I have pictures to post.