random user submitted photo

Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

Do you still need to fabricate the solid aluminum blocks for the service bulletin?

John Gillis

SEL Private, Comm Glider, Tow pilot (Pawnee Driver)

Waiex N116YX, Jabiru 3300, Tail dragger,

First flight, 3/16/2013. 403 hours and climbing.

Home: CO15. KOSH x 5

Flying a B-Model Conversion (Super Bee Baby!)

-

fastj22 - Posts: 1594

- Joined: Sun Aug 21, 2011 5:56 pm

- Location: Mile High

Re: Cotton Waiex 191 - N191YX

John,

I have already fabricated and pilot drilled those blocks.

I have already fabricated and pilot drilled those blocks.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

I am teaching Adam to be lazy. We have a bunch of 1/4" holes to drill for the southcos. Of course we go up in steps. Showed him how we change one drill size at a time then run it through each hole. Common sense of course but having it told to you and then doing it is a shortcut to the lazy way of thinking.

The next lesson in lazy is how to deburr the 1/4" holes in stainless. We used a ball stone in the dremel. Works great and is fast.

None of you guys ever answered one of my questions - is 1/4" for the southcos good or should I go to 5/16"? Replies gratefully accepted. Not too late for me to take advantage of it.

The next lesson in lazy is how to deburr the 1/4" holes in stainless. We used a ball stone in the dremel. Works great and is fast.

None of you guys ever answered one of my questions - is 1/4" for the southcos good or should I go to 5/16"? Replies gratefully accepted. Not too late for me to take advantage of it.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

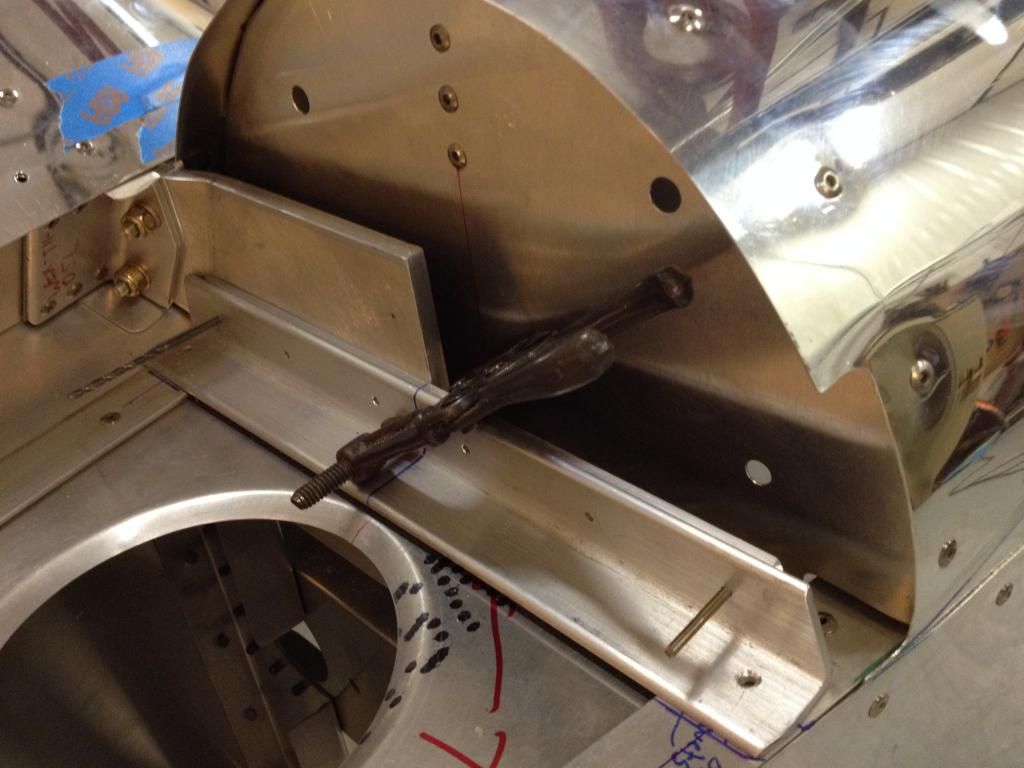

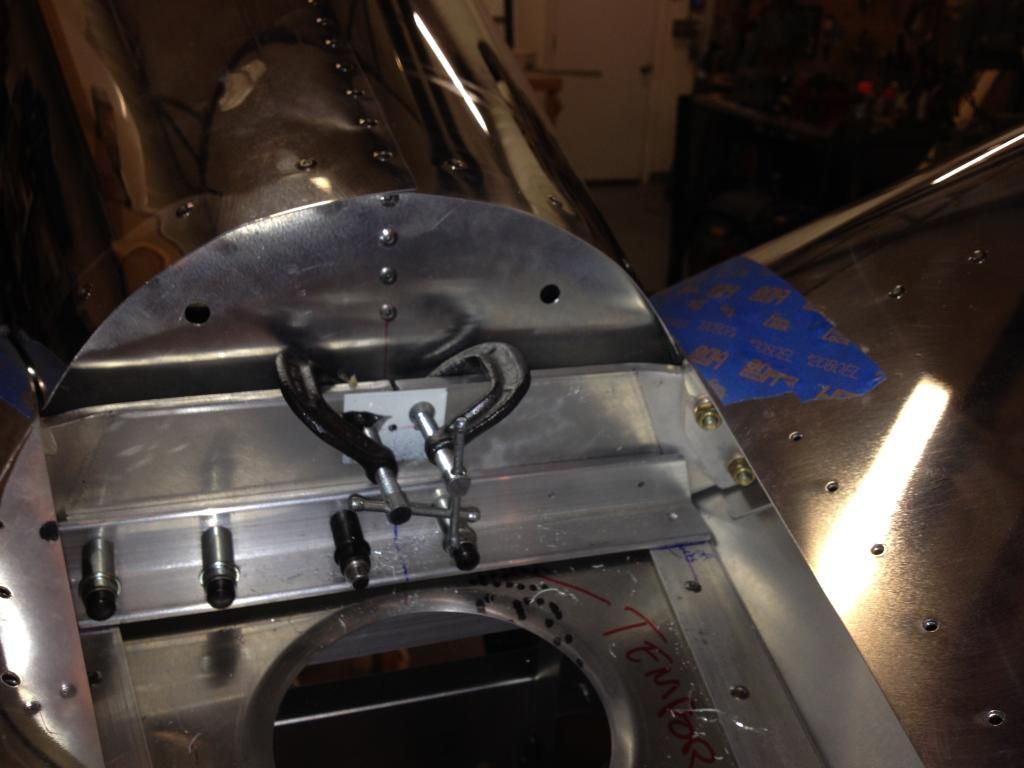

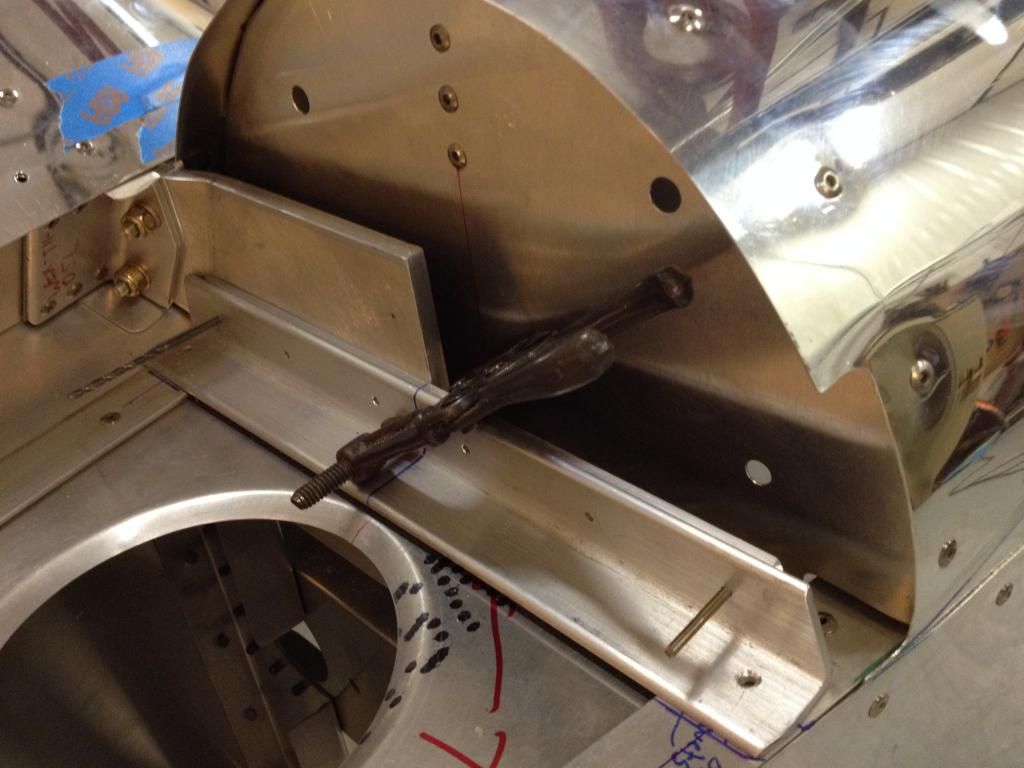

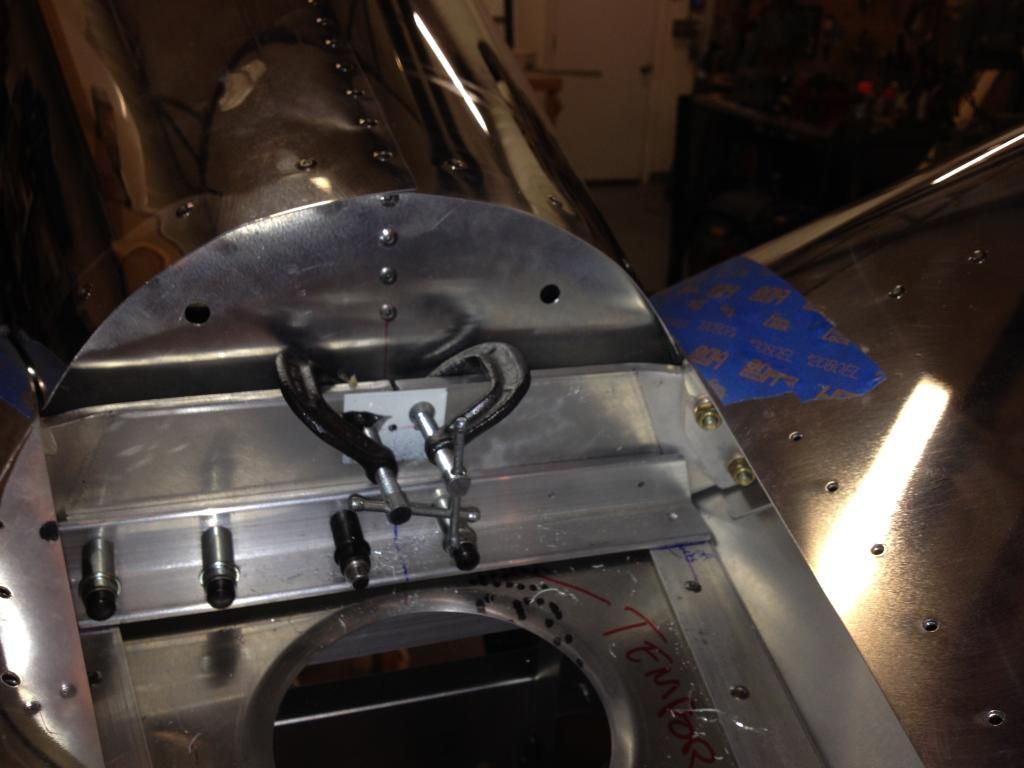

So, I am remaking the WIX-F22-06 angle. First one was the Sonex part. The holes did not line up perfectly with the verticals so I remade it. Second one did not have edge distance due to the new hockey stick bend (I think) so I made #3 with a longer flange. Found out it interfered with the WIX-F22-04 angle. Put a step in the #3 angle and didn't like it. Decided to use a shim. Made #4 using the shim to offset the holes but screwed up somehow - offset at .020 on one end, .049 at the other end for a .032 shim. I don't want to jinx myself, but #5 looks good.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Shim story:

The F22-04 angle was .032. I don't have much .032 stock. I had considered using .040 as I have a bunch of that. But in hunting around the hangar, I found the roof of the old 140 fuselage. It was the airplane Adam and Matthew both took their first rides in, when they were 5. The roof was .032. I hacked out a piece. Now every time we fly the Waiex we will be flying a part of the 140.

Lest you think I am a parts waster, I saved the roof for the window frames and stiffeners. Any restorer worth his or her salt will use a new piece of metal for the roof.

The F22-04 angle was .032. I don't have much .032 stock. I had considered using .040 as I have a bunch of that. But in hunting around the hangar, I found the roof of the old 140 fuselage. It was the airplane Adam and Matthew both took their first rides in, when they were 5. The roof was .032. I hacked out a piece. Now every time we fly the Waiex we will be flying a part of the 140.

Lest you think I am a parts waster, I saved the roof for the window frames and stiffeners. Any restorer worth his or her salt will use a new piece of metal for the roof.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Working the tail mounting. On my next Waiex I am definitely doing this with the turtledeck off. I think Ryan tried to tell me that.

I ended up shimming the lower angle back like Ryan did.

I ended up shimming the lower angle back like Ryan did.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Some backwards progress- took out the aft turtledeck bulkhead. Waiex builders, don't rivet it in until the tail is on for keeps. Impossible to clamp when it is on and impossible to tighten the nuts.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

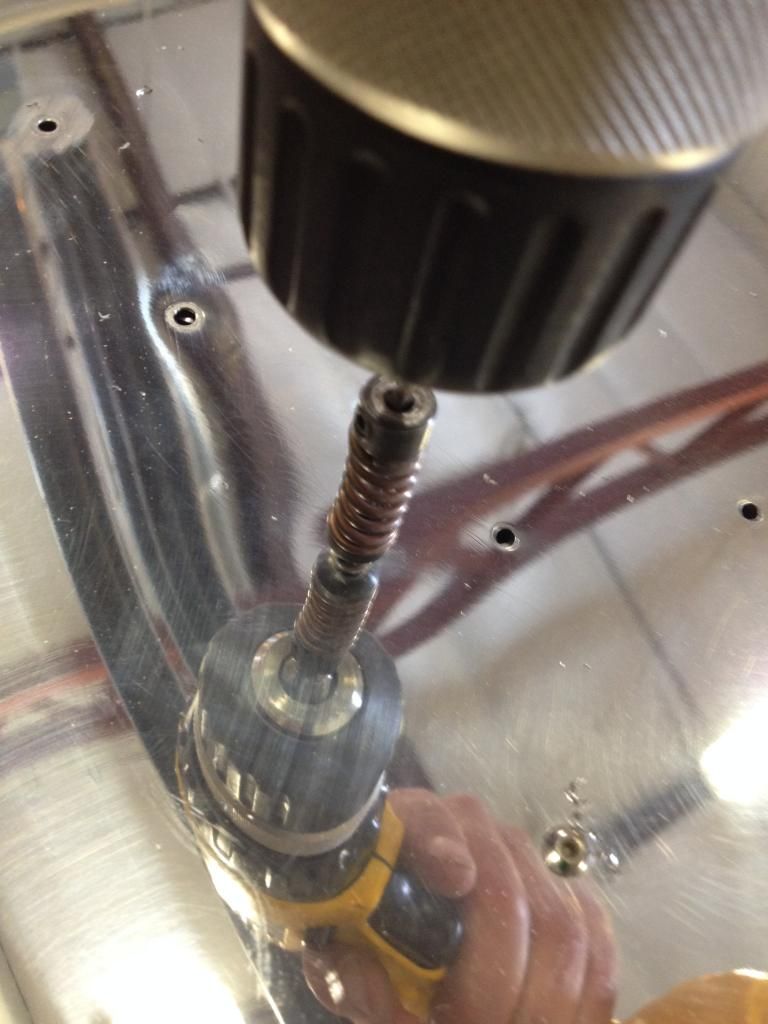

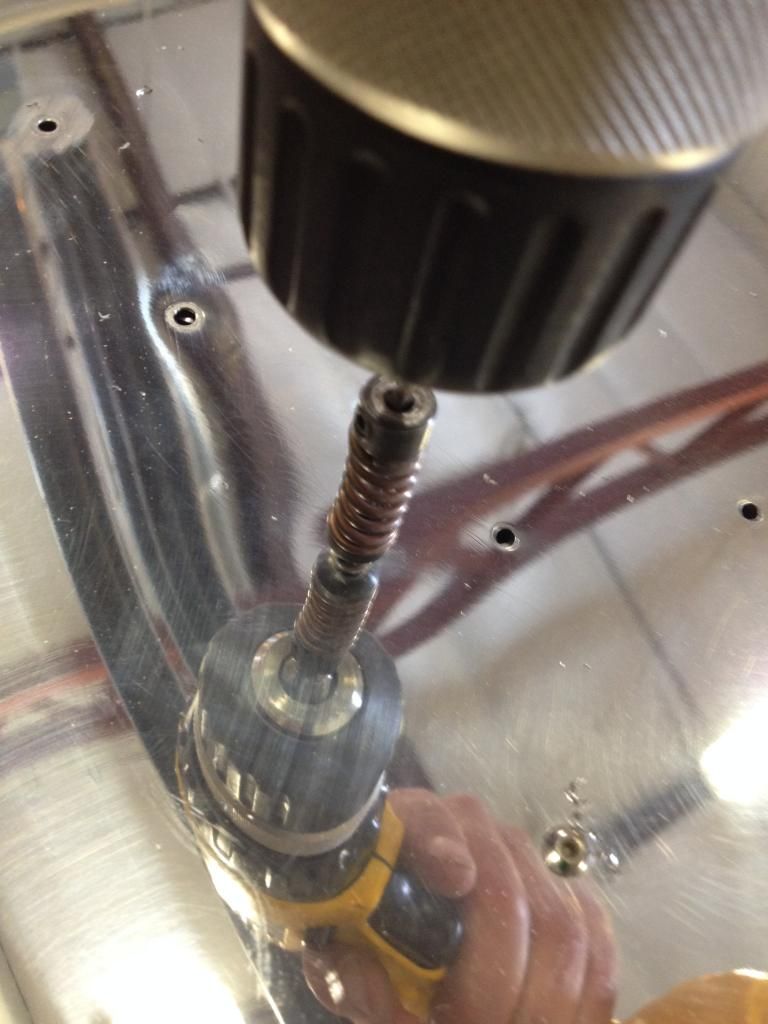

I am bummed out. Destroyed a hockey stick, angle, shim, and the .75" beef up block. This hole was #21 but is screwed up enough that I am not sure I can save it with a .25" hole.

Control-Z

I have figured out that the drill stop is a lifesaver when drilling out these infernal steel rivets.

This part is too critical to screw with.

Control-Z

I have figured out that the drill stop is a lifesaver when drilling out these infernal steel rivets.

This part is too critical to screw with.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5490

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Sorry to hear that Bryan. I too had issues with parts today and had to redrilled and remake some small angles. Hopefully you can recover from this quickly.

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton Waiex 191 - N191YX

May I help help you to drill rivets out?

Take a used mandrel and insert the mandrel into the rivet that you want to remove. From the side that you pulled and the side of the mandrel that did not broke of. Now a few light taps with a light hammer, knock the centre piece from the mandrel.

Now drill the rivet out with the same size drill that you used to updrill. Prevebly an electric drill, the rivet must not spin!

Practice first on some junk

Take a used mandrel and insert the mandrel into the rivet that you want to remove. From the side that you pulled and the side of the mandrel that did not broke of. Now a few light taps with a light hammer, knock the centre piece from the mandrel.

Now drill the rivet out with the same size drill that you used to updrill. Prevebly an electric drill, the rivet must not spin!

Practice first on some junk

- hsjvorster

- Posts: 12

- Joined: Thu Jun 23, 2011 5:09 am

Who is online

Users browsing this forum: No registered users and 12 guests