random user submitted photo

Cotton Waiex 191 - N191YX

Re: Cotton Waiex 191 - N191YX

One of the holes in the Ti gear leg was 1/32" in too far. So i shortened the other leg by 1/32" to put the axle in the right spot. I don't have a lathe. Ti is pretty when it burns.

Legs are located, axles stuck on at the moment.

On the gear some year!

Legs are located, axles stuck on at the moment.

On the gear some year!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Yes it is pretty. My son had a pretty interesting fire from cutting Ti at work. That stuff can be volatile at times. I'm glad it worked out for you. Looks Good!

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Re: Cotton Waiex 191 - N191YX

I was fairly careful. Cleaned up all the sawdust. Had pieces of steel to catch the sparks. I would have preferred to do a better job on the holes, but they are done and I am moving on!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Try 1 for gear alignment. Went to my extrusion collection and found .5" square tube which was nearly the perfect length, and 3/16" thick 1.5" angle which was over long. Decided to use the square tube as it was less unwieldy.

Found the tube had a twist in it so I am going to switch to the angle. I got a piece of oak from the scrap pile which I sawed in half to block the extrusion off the angle.

I have a #30 pilot hole in each axle, just on one side. When I have things aligned I will transfer that hole to the Ti gear just deep enough to get it located, then I will head to the drill press/V block. After I have the hole to 1/4" I will run the bit through to put the hole in the other side of the axle.

Found the tube had a twist in it so I am going to switch to the angle. I got a piece of oak from the scrap pile which I sawed in half to block the extrusion off the angle.

I have a #30 pilot hole in each axle, just on one side. When I have things aligned I will transfer that hole to the Ti gear just deep enough to get it located, then I will head to the drill press/V block. After I have the hole to 1/4" I will run the bit through to put the hole in the other side of the axle.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Awesome Bryan, that's pretty much how I did it.

T-minus 7:22 mins central time until the New Year

T-minus 7:22 mins central time until the New Year

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Re: Cotton Waiex 191 - N191YX

Thanks Scott, good to hear. I was amazed that I remembered where I put the gear aligning tool, those little tube pieces. I will not make it on the gear by the new year, our battle cry is now on the gear in the new year. Still we are getting close.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

This is how deep I transferred the hole. Not much.

Lots of Ti swirleys and oil. This Ti should never rust.

Happy New Year all!

Lots of Ti swirleys and oil. This Ti should never rust.

Happy New Year all!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

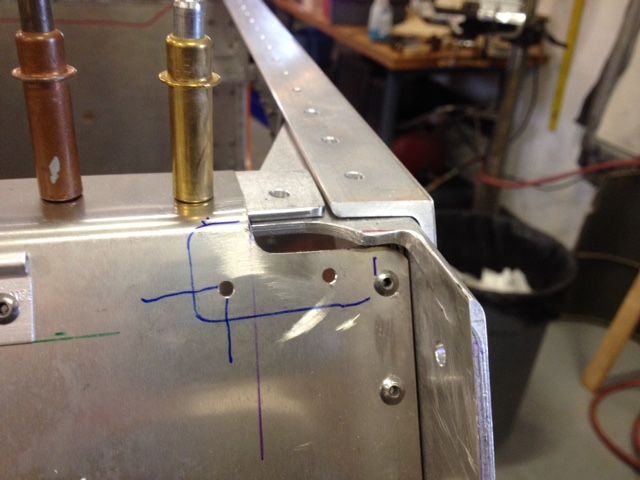

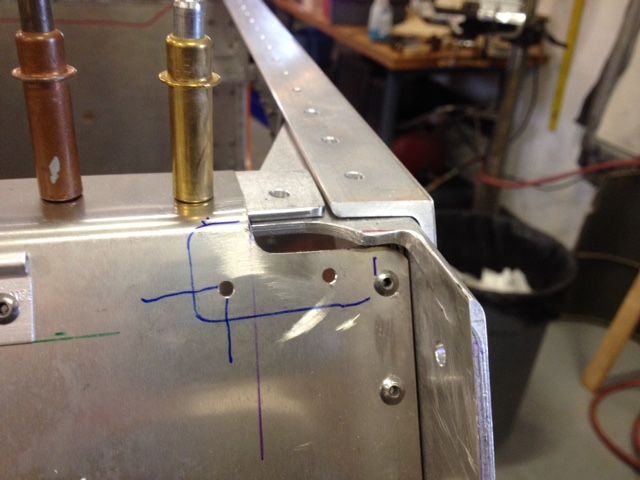

I got a little crazy trimming the bottom corners of the firewall. Had these big gaps.

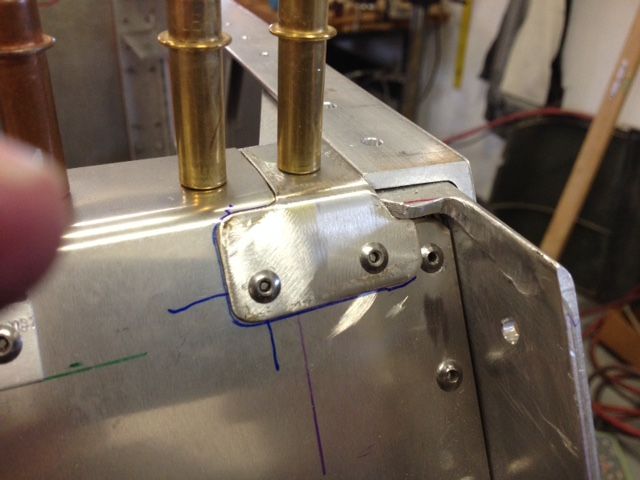

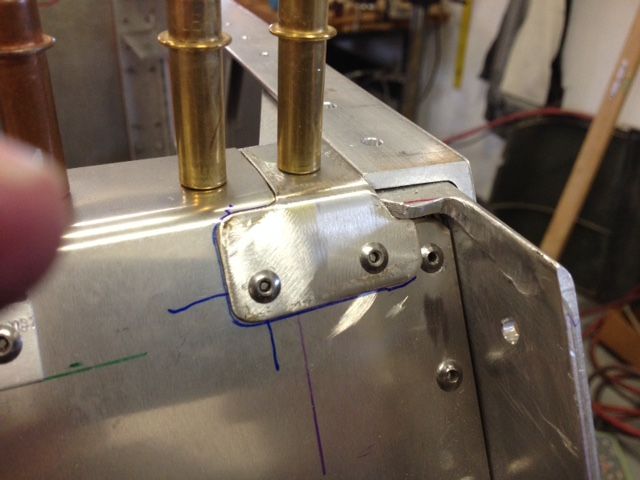

Patched them.

This nut and washer, the bottom most one, was hard to get on. Taped the washer to the nut and was able to slide them in place.

Three out of 8 bolts so far, mount is going on!

Patched them.

This nut and washer, the bottom most one, was hard to get on. Taped the washer to the nut and was able to slide them in place.

Three out of 8 bolts so far, mount is going on!

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

Those with sharp eyes may have noticed the picture above is wrong on two accounts. One is that I used a nylock nut rather than an all metal locknut. The other is that it is a 3/16" rather than a 1/4" fastener. In my ignorance I thought the -S100 bolts were sort of the same thing as the -S54 bolts but nearly twice as long. I am less ignorant now and I used the right bolts!

As others have mentioned I had to trim the bottom most bolts so they didn't hit the gear tubes. I would like to hear from those with stronger Kung-Fu than I on how they torqued them. Mine are guten tight right now.

These bolts were a little long but I had plenty of washers:

Actually they were too short, the washers prevent a cycle on the locking part of the nut, and make it obvious that something is amiss. I will buy some -S102's on my next order.

I have a #30 hole drilled through my tailwheel spring mount and the Ti rod. Getting closer to having a tailwheel.

One of these days I am going to need to assemble my wheels.

As others have mentioned I had to trim the bottom most bolts so they didn't hit the gear tubes. I would like to hear from those with stronger Kung-Fu than I on how they torqued them. Mine are guten tight right now.

These bolts were a little long but I had plenty of washers:

Actually they were too short, the washers prevent a cycle on the locking part of the nut, and make it obvious that something is amiss. I will buy some -S102's on my next order.

I have a #30 hole drilled through my tailwheel spring mount and the Ti rod. Getting closer to having a tailwheel.

One of these days I am going to need to assemble my wheels.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cotton Waiex 191 - N191YX

I chucked the wheels on. Still need to get some of the right bolts so I can fasten for keeps. I am using scrap hamsterwheel plywood as wheel spacers for the picture. Still, does me good.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5492

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Who is online

Users browsing this forum: No registered users and 8 guests