random user submitted photo

Joggle technique

2 posts

• Page 1 of 1

Joggle technique

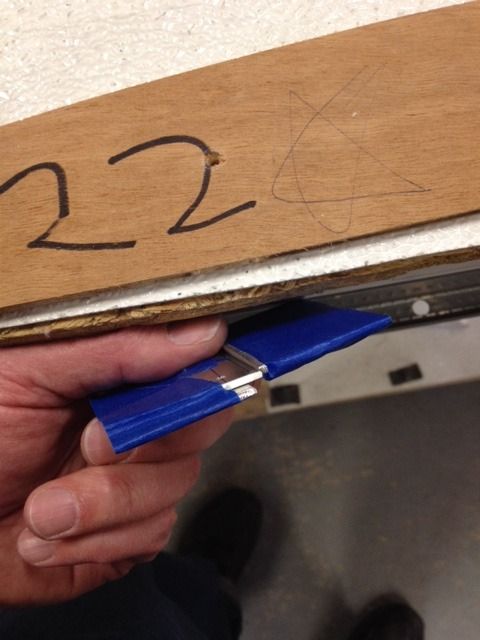

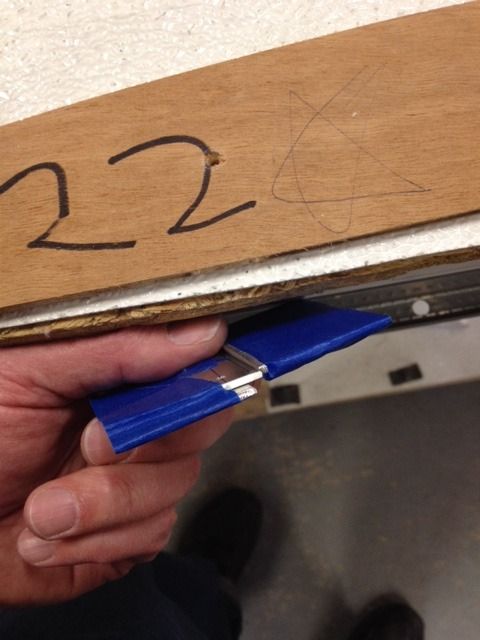

I first figured out this technique when I was installing a leading edge landing light in a C140. Shown below are the instrument panel cross tie plates. The bottom of my panel was .070" high, so I either needed to shim or joggle. I took a couple of .090" scrap pieces and put a radius on one edge. Then I taped them to the piece I wanted to joggle:

Then you put the part in the vise and honk down on it. Make sure you polish the edges first!

Came out good, no extra shim weight required, and I have .070" of extra legroom.

The .090" shims worked good for this case due to springback. Always good to work it out in scrap first.

Then you put the part in the vise and honk down on it. Make sure you polish the edges first!

Came out good, no extra shim weight required, and I have .070" of extra legroom.

The .090" shims worked good for this case due to springback. Always good to work it out in scrap first.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5071

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Joggle technique

thanks for the tip!

-

kevinh - Posts: 369

- Joined: Mon Feb 23, 2015 10:46 pm

- Location: San Mateo, CA

2 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 5 guests