Upholstery

I've been sitting on cushion squabs and pads of memory foam to help deal with the cold - winter flying the Sonex.

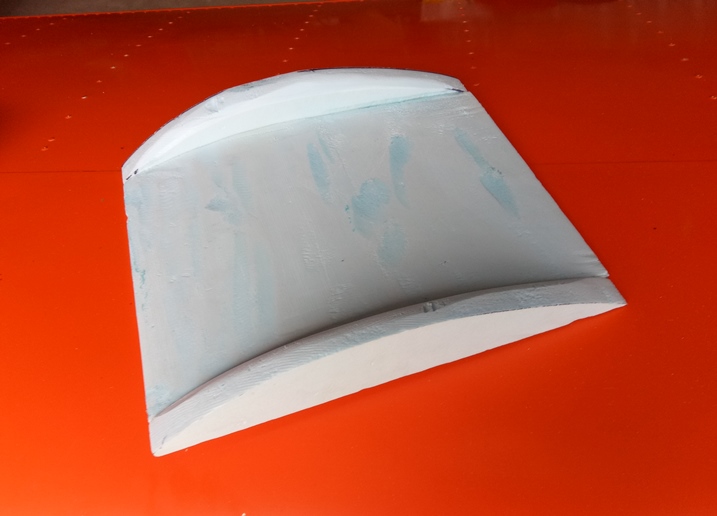

Came across these at a sale price. Memory foam, and if you flip it over and a little needle work on the "notch" - this can be made to work for a dual stick machine. I'm going to dispense with the bench padded nylon and use these which offer thicker memory foam and more insulation. In effect the finished look will be an aluminium bench and back with upholstered squabs velcroed in place.

Each cushion weighs 1.5lb

Not for everyone - but at this remaindered price....

https://www.bedbathandbeyond.com/store/ ... ey/5374570

Came across these at a sale price. Memory foam, and if you flip it over and a little needle work on the "notch" - this can be made to work for a dual stick machine. I'm going to dispense with the bench padded nylon and use these which offer thicker memory foam and more insulation. In effect the finished look will be an aluminium bench and back with upholstered squabs velcroed in place.

Each cushion weighs 1.5lb

Not for everyone - but at this remaindered price....

https://www.bedbathandbeyond.com/store/ ... ey/5374570