random user submitted photo

Gear leg length

13 posts

• Page 1 of 2 • 1, 2

Gear leg length

So my plans say 34" for length, but my parts are 1/8" longer than that. I am tempted to leave that 1/8" on and deprive myself of the joy of cutting the ti rod. Anybody else guilty?

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5491

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Gear leg length

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Re: Gear leg length

This is an old photo. The SB has been done on the bolts.

Dana Baker

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

Scratch Built

First Flight March 8, 2015

Sonex #1534 - N1534S "Aluminum Foil"

Aerovee-Dual Controls-Tail Dragger

- Gripdana

- Posts: 479

- Joined: Fri Jan 11, 2013 5:59 pm

Gear leg length

I am with Dana - the extra is sticking out the top a little bit.

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

Robbie Culver

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

-

Sonex1517 - Posts: 1670

- Joined: Fri Jun 03, 2011 10:11 am

- Location: T25 Aero Estates, Frankston, TX

Re: Gear leg length

Well, I guess I'll have to slide that hole down a bit then.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5491

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Gear leg length

I am also going to install AN4H-30 bolts at the recommendation of someone who suffered through a failure.

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

Robbie Culver

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

-

Sonex1517 - Posts: 1670

- Joined: Fri Jun 03, 2011 10:11 am

- Location: T25 Aero Estates, Frankston, TX

Re: Gear leg length

What is the AN4H-30 bolt and why is it needed? Is it hard to find or install?

Waiex 158 New York. N88YX registered.

3.0 Liter Corvair built, run, and installed.

Garmin panel, Shorai LiFePo batteries.

3.0 Liter Corvair built, run, and installed.

Garmin panel, Shorai LiFePo batteries.

- GordonTurner

- Posts: 668

- Joined: Tue Feb 21, 2012 1:14 am

- Location: NY, NY

Re: Gear leg length

Typed in a long reply and my darn iphone lost it. Trying again on from Ubuntu.

Gordon,

AN4H is a 1/4" AN bolt with a drilled head for safety wire. I assume it is wired so the bolt doesn't fall out if it breaks, but I don't know.

No problems drilling the Ti. I drilled up in 3 steps, #30, 3/16", and 1/4". Slow going with the #30, lots of clearing of the chips and time to cool down. Bought fancy "cold fire" bits for the 3/16" and 1/4". The 3/16" worked ok, the 1/4" bit died immediately. Took out a plane jane black oxide 1/4" bit from sears and it drilled through no problem. I used the idea attributed to Bob Mika, didn't drill through until the very end so the hole would hold oil. That was genius. I used MM air tool oil rather than WD40. Started with WD40 but it was working poorly for me.

So my gear legs fit tight in the sockets, which is good. Hard to align the 1/4" hole in the motor mount with the 1/4" hole in the gear leg due to friction. I think I will taper a 1/4" steel rod and tap it in. Anybody want to share their technique? I plan to align the holes then finish drilling through the back of the motor mount.

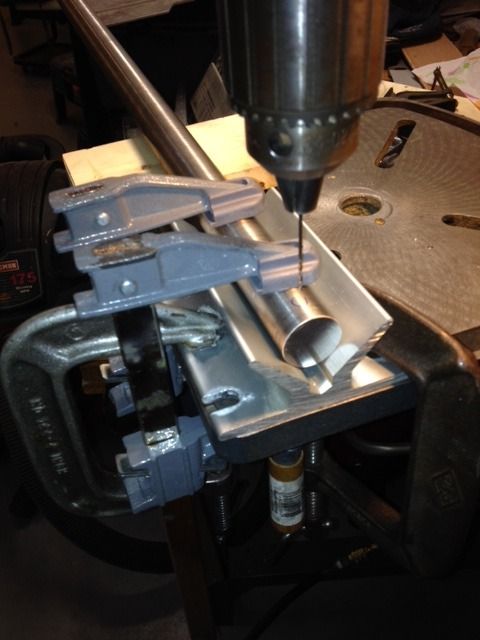

Here is my drill press setup:

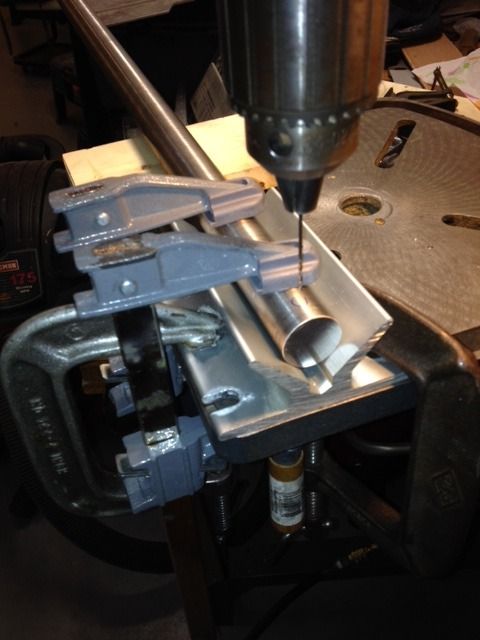

Here is the first leg stuck in:

Gordon,

AN4H is a 1/4" AN bolt with a drilled head for safety wire. I assume it is wired so the bolt doesn't fall out if it breaks, but I don't know.

No problems drilling the Ti. I drilled up in 3 steps, #30, 3/16", and 1/4". Slow going with the #30, lots of clearing of the chips and time to cool down. Bought fancy "cold fire" bits for the 3/16" and 1/4". The 3/16" worked ok, the 1/4" bit died immediately. Took out a plane jane black oxide 1/4" bit from sears and it drilled through no problem. I used the idea attributed to Bob Mika, didn't drill through until the very end so the hole would hold oil. That was genius. I used MM air tool oil rather than WD40. Started with WD40 but it was working poorly for me.

So my gear legs fit tight in the sockets, which is good. Hard to align the 1/4" hole in the motor mount with the 1/4" hole in the gear leg due to friction. I think I will taper a 1/4" steel rod and tap it in. Anybody want to share their technique? I plan to align the holes then finish drilling through the back of the motor mount.

Here is my drill press setup:

Here is the first leg stuck in:

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5491

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Gear leg length

Bryan,

I had a different gear arrangement, but did the drilling in stages similar to how you're doing it. Every stage I updrilled I would start with the gear In the weldments (or motor mount for your case), then remove the TI leg and finish in the drill press, then transfer back to the mount so I could finish the through drilling of the mount so the hole was straight. Not sure if that makes sense or helps you out...but it mostly worked for me.

I had a different gear arrangement, but did the drilling in stages similar to how you're doing it. Every stage I updrilled I would start with the gear In the weldments (or motor mount for your case), then remove the TI leg and finish in the drill press, then transfer back to the mount so I could finish the through drilling of the mount so the hole was straight. Not sure if that makes sense or helps you out...but it mostly worked for me.

Scott Meyer

Sonex 1629 - Sold...9/2019

Sonex 1629 - Sold...9/2019

- ScottM-Sonex1629

- Posts: 441

- Joined: Sun Aug 11, 2013 10:00 pm

- Location: Dublin, Ohio (MRT)

Gear leg length

GordonTurner wrote:What is the AN4H-30 bolt and why is it needed? Is it hard to find or install?

Per the guy that suggested it, as Bryan explained these bolts (available through Aircraft Spruce for about $5 each) have a drilled head and drilled thread.

I believe the suggestion stemmed from broken bolts resulting in a gear failure with damage to the aircraft. The idea being that if the safety wire is done correctly, the bolts breaking would not result in the gear departing or collapsing.

I am paraphrasing. I have not had the issue personally.

Maybe someone with more knowledge than I can interject.

Robbie Culver

Sonex 1517

Chicagoland

Tails and Wings complete - finishing fuselage.

N1517S reserved

Robbie Culver

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

Sonex 1517

Aero Estates (T25)

First flight 10/10/2015

375+ hours

Jabiru 3300 Gen 4

Prince P Tip

Taildragger

N1517S

-

Sonex1517 - Posts: 1670

- Joined: Fri Jun 03, 2011 10:11 am

- Location: T25 Aero Estates, Frankston, TX

13 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 5 guests